A kind of VOC-reducing masterbatch for polypropylene and its preparation method and application

A polypropylene and masterbatch technology, applied in the field of polymer composite materials, can solve the problem of high cost of devolatilization process, achieve rich foam, improve devolatilization effect, and simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Required raw materials: microporous foamed polypropylene carrier (XP100-84) from Germany Marborui company, the polypropylene carrier cell size is less than 10 microns, and the cell density is greater than 10 9 / cm 3 , has good compatibility and adsorption to VOC remover and surfactant; the surfactant comes from DuPont Company of the United States, the surfactant does not contain any VOC, and can provide excellent performance of reducing surface tension, suitable for various System; VOC remover—pure water, purity ≥99.9%.

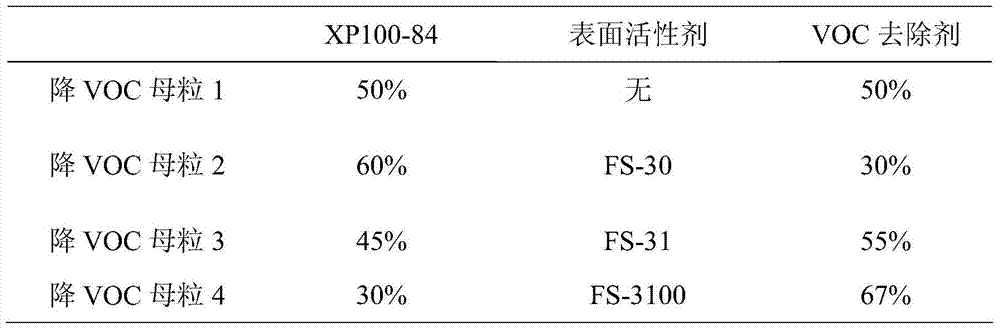

[0033] A VOC-reducing masterbatch for polypropylene, according to the mass percentage of raw materials, its components are formulated according to the following table 1:

[0034] Table 1

[0035]

[0036] According to the proportion of ingredients in Table 1, first mix the pure water and the surfactant, stir evenly, then add it to the polypropylene carrier, mix at a stirring speed of 15rpm for 10min, and evenly absorb the VOC remover in the polypr...

Embodiment 2

[0039] a. Preparation of VOC-reducing masterbatch for polypropylene

[0040]Required raw materials: Microporous foamed polypropylene carrier (XP100-84) is from Germany Marborui; domestic foamed PP is from Hefei Huitong New Material Co., Ltd.; surfactant is from DuPont, USA; VOC remover—10% weak.

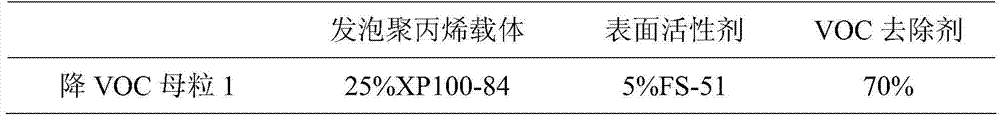

[0041] A VOC-reducing masterbatch for polypropylene, according to the mass percentage of raw materials, its components are formulated according to the following table 2:

[0042] Table 2

[0043]

[0044]

[0045] According to the above ratio, first mix pure water and surfactant, stir evenly, then add to the polypropylene carrier, mix at a stirring speed of 1000rpm for 3 minutes, so that the VOC remover is evenly adsorbed in the polypropylene carrier, and the VOC-reducing masterbatch is obtained.

[0046] b. Application of VOC-reducing masterbatches for different types of polypropylene

[0047] Required raw materials: polypropylene resin PP-045, from Shandong Hengyuan Chemic...

Embodiment 3

[0057] a. Preparation of VOC-reducing masterbatch for polypropylene

[0058] Required raw materials: Microcellular foamed polypropylene carrier (XP100-84) is from Mulberry Company in Germany; surfactant FS-31 is from DuPont Company in the United States; VOC remover—pure water, 20% propanol and butanol (1: 1) Mixture aqueous solution, 30% propanol aqueous solution, 50% ethanol aqueous solution.

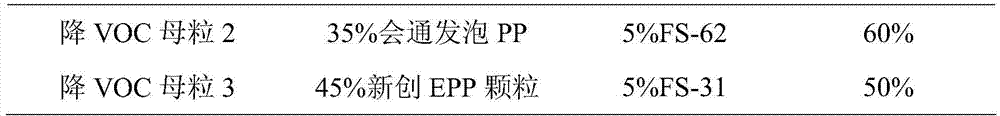

[0059] A VOC-reducing masterbatch for polypropylene, according to the mass percentage of raw materials, its components are formulated according to the following table 5:

[0060] table 5

[0061]

[0062] According to the above ratio, first mix pure water and surfactant, stir evenly, then add to the polypropylene carrier, mix at a stirring speed of 1000rpm for 3 minutes, so that the VOC remover is evenly adsorbed in the polypropylene carrier, and the VOC-reducing masterbatch is obtained.

[0063] b. Application of VOC-reducing masterbatches for different types of polypropylene

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell size | aaaaa | aaaaa |

| Cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com