A method for reactive extrusion copolymerization of vinyl monomers

A vinyl monomer, reactive extrusion technology, applied in the field of vinyl monomer reactive extrusion copolymerization, can solve the problems of production capacity constraints, additional monomers, ratio constraints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

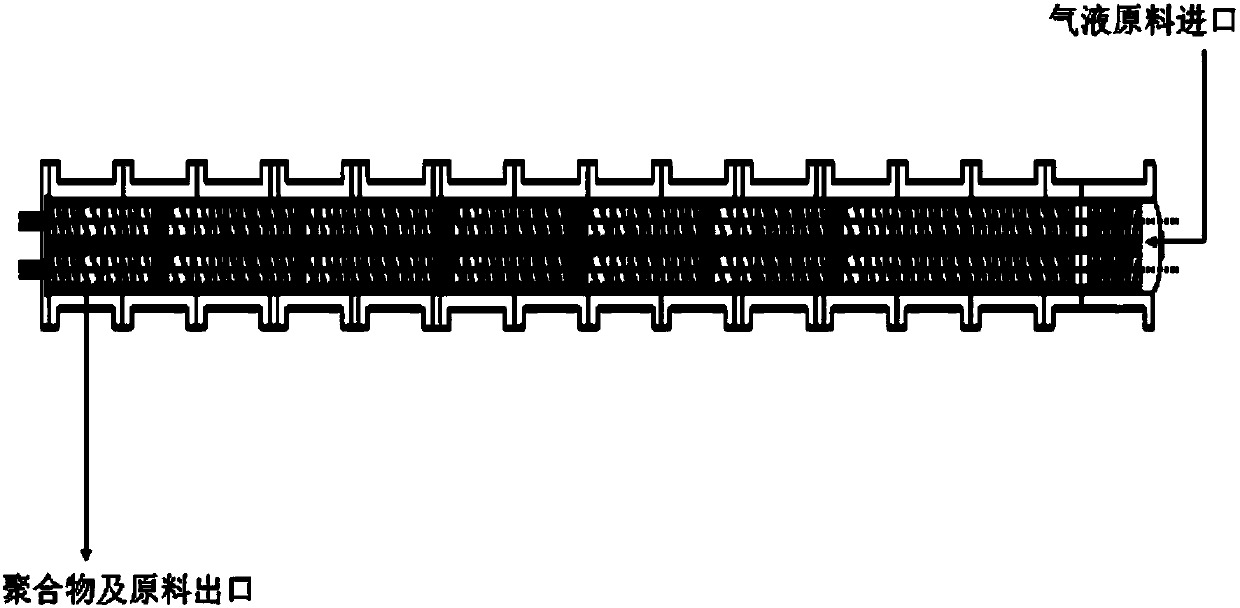

Embodiment 1

[0047] Methyl methacrylate (MMA) was selected as the vinyl monomer, maleic anhydride (MAH) was selected as the vinyl comonomer, and the mass ratio of the two was 95.2:4.8. reactivity ratio r MMA and r MAH They are 6.7 and 0.02 respectively, indicating that MMA is more likely to self-polymerize, while MAH tends to be copolymerized, which is obviously not conducive to the appearance of MAH on the copolymer molecular chain, so it is necessary to strengthen the content of MAH raw materials at the initial stage of polymerization. MAH is dissolved in MMA, the mass ratio of the two is 88.9:11.1, and the benzoyl peroxide (BPO) of the two total amount 0.93% mass fraction is added therein, then with the metering of 1.54kg / h Speed, using a diaphragm pump with an ultimate pressure of 15MPa to input a Ф35, length-to-diameter ratio: L / D=60, such as figure 1 In the reverse flow structure shown, the first screw section of the co-rotating tightly intermeshing twin-screw extruder, the tempera...

Embodiment 2

[0054] Styrene (St) was selected as the vinyl monomer, and maleic anhydride (MAH) was selected as the vinyl comonomer, and the mass ratio of the two was 97.09:2.91. Since the reactivity ratio of the two belongs to the ideal alternating copolymerization, the component ratio of the copolymer is the same as the raw material ratio, so there is no need to consider strengthening the raw material to strengthen the reaction in advance. Then choose styrene-butadiene-styrene triblock thermoplastic elastomer (SBS), molecular weight is 1.5×10 5 , dissolved in the above two mixed monomers, the mass ratio of mixed monomers to SBS is 7.5:2.5. Azobisisobutyronitrile is selected as the initiator, and the addition amount is 1.2% by mass fraction of the total amount of the two mixed monomers. Then, with a metering rate of 3.6kg / h, a diaphragm pump with an ultimate pressure of 15MPa is used to input a twin-screw power inlet with a pressure resistance of 1MPa and no leakage Ф35, the length-to-dia...

Embodiment 3

[0060] Styrene (St) was selected as the vinyl monomer, acrylonitrile (AN) and glycidyl methacrylate (GMA) were selected as the vinyl comonomer, and the mass ratio of the three was 69.9:30:0.1. Since the reactivity ratios of AN, GMA and St are all less than 1, the component ratio of the copolymer can be regarded as the same as the raw material ratio, so there is no need to consider strengthening the raw material to strengthen the reaction in advance.

[0061] The three of St, AN and GMA are evenly mixed together, and the benzoyl peroxide (BPO) of the three total amount 0.80% mass fraction is added therein, then with the metering rate of 1.54kg / h, the ultimate pressure is 15MPa diaphragm pump input a Ф40, aspect ratio: L / D = 65, such as figure 1 Shown is the first screw section of the co-rotating tight-meshing twin-screw extruder with reverse flow structure, and the temperature of the screw barrel is set at 70-110°C according to the requirements of the polymer molecular weight. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com