Internal component of falling film devolatilization tower with bionic structure and devolatilization tower

A technology of devolatilization tower and internal components, applied in the field of devolatilization tower, can solve the problems of uncontrollable falling film time, uneven residence time, low devolatilization efficiency, etc., achieving good commercial significance, enhancing membrane surface renewal, The effect of strengthening the devolatilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

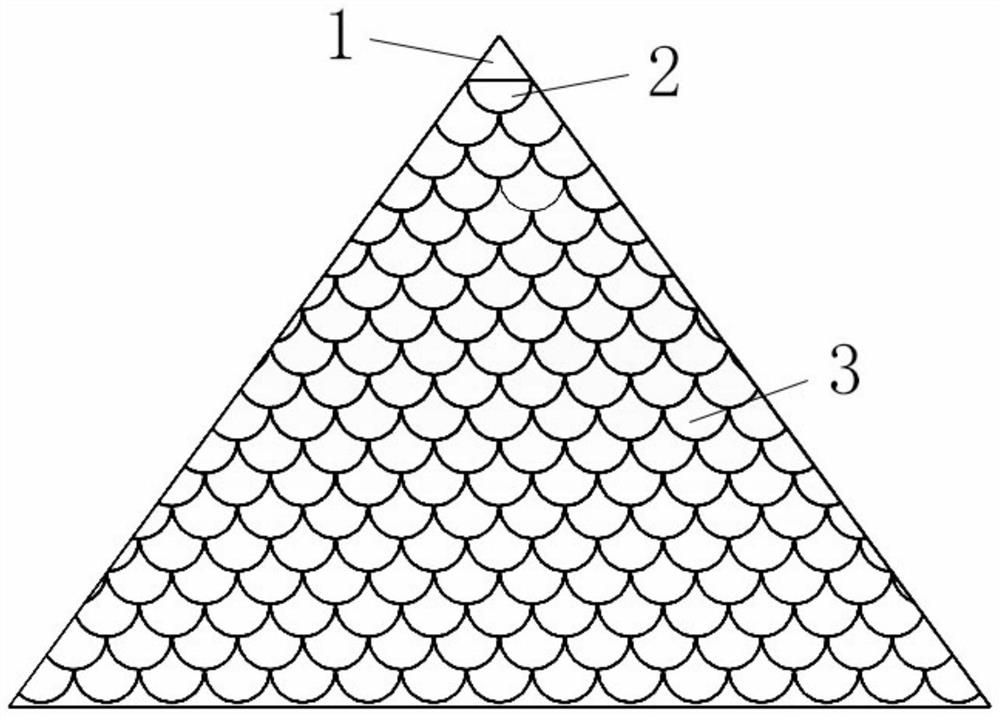

[0045] A bionic structure falling film devolatilization tower internal component, a bionic structure falling film devolatilization tower internal component, including a column plate body 1, a support member 6 located at the bottom of the column plate body, and a falling film member 2 located on the surface of the column plate body. , a plurality of bionic structural elements 3 are arranged in the falling film member, and the support member 6 is used to increase the fluid film forming area.

[0046] In this embodiment, the falling film components are distributed on the surface of the tray body, and are arranged into several layers of falling film components, and the distance between the two adjacent layers of the falling film components is the same.

[0047] Further, the column plate body is a conical column plate, the upper end of the column plate body is a cone angle, and the number of bionic structural elements in the falling film assembly increases sequentially along the flu...

Embodiment 2

[0063] This embodiment is carried out on the basis of the above-mentioned first embodiment, and the same points as the above-mentioned embodiment will not be repeated.

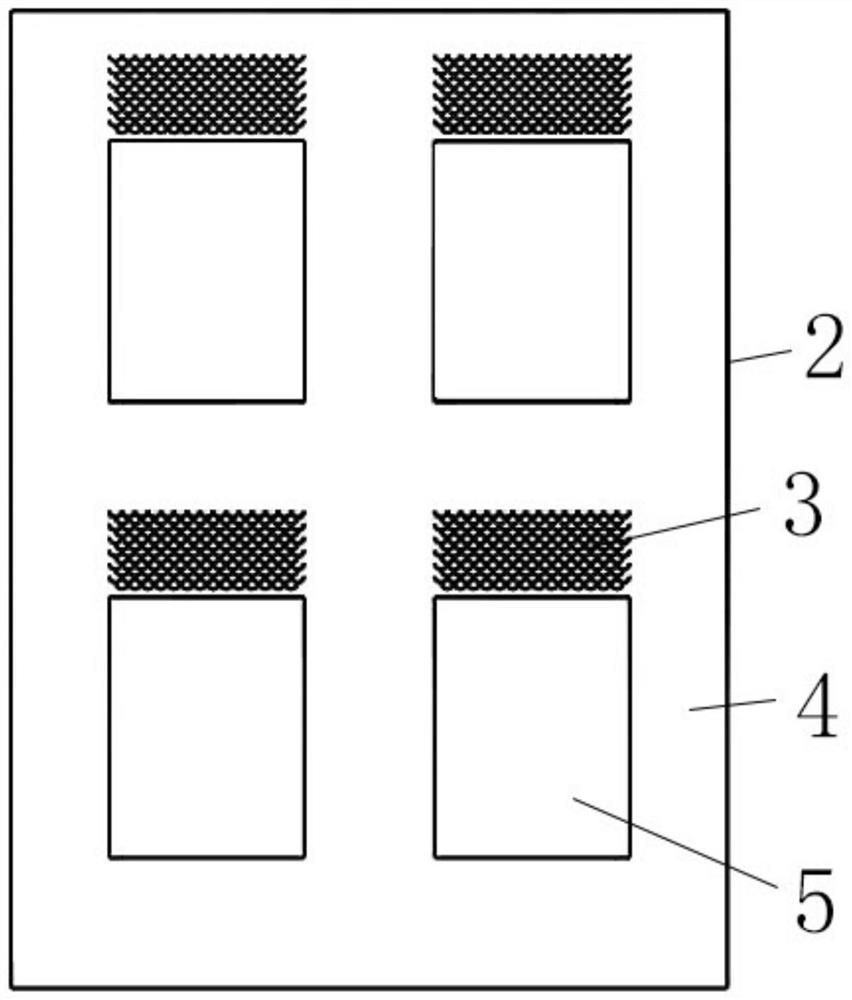

[0064] In this embodiment, the falling-film components are distributed below the column body, the falling-film components include a falling-film plate 4 with a window 5, and the bionic structural element is located in the falling-film plate with a window. place.

[0065] Further, a plurality of the biomimetic structural elements are evenly arranged above the window of the falling film plate, two adjacent rows of biomimetic structural elements are arranged at intervals, and the biomimetic structural elements in the upper row partially cover the biomimetic structural elements in the next row. on structural elements.

[0066] Further, the length of each window is: 10-200mm, more preferably 20-100mm; the height of each window is: 10-200mm, more preferably 20-100mm; the spacing between adjacent windows is 10-100mm...

Embodiment 3

[0068] This embodiment is carried out on the basis of the above-mentioned first or second embodiment, and the same points as the above-mentioned embodiment will not be repeated.

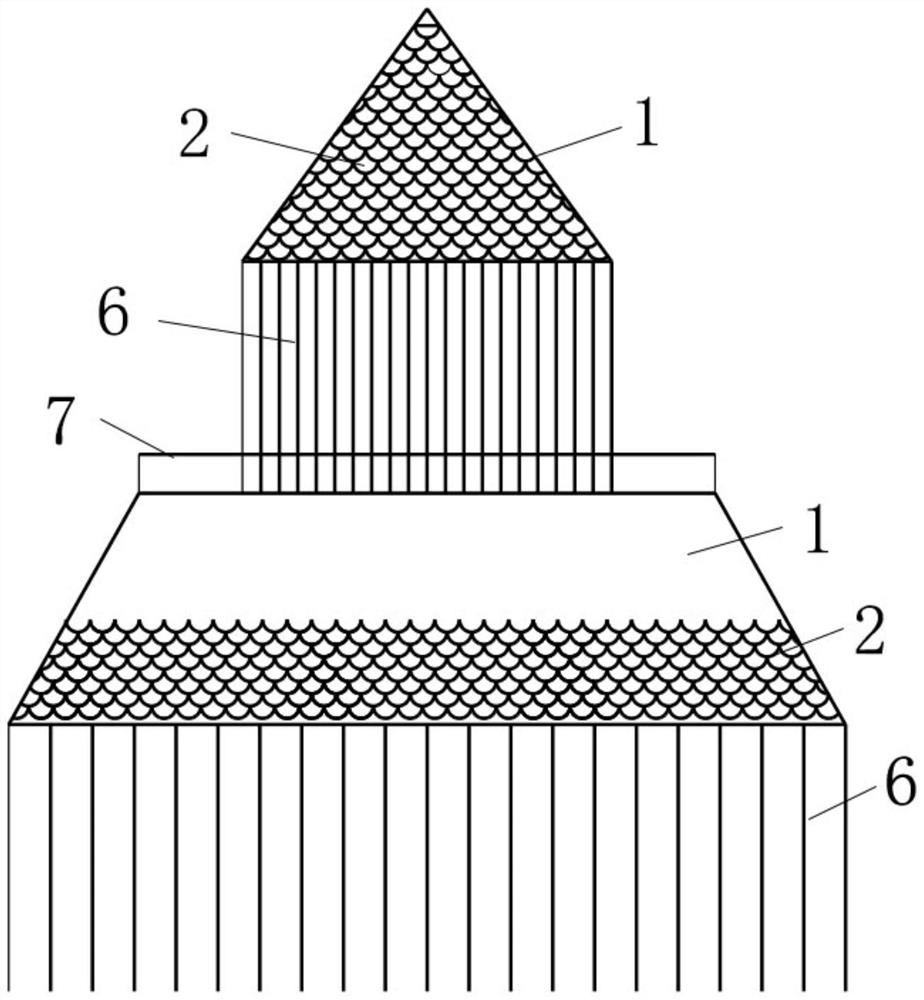

[0069] like image 3 As shown, this embodiment mainly introduces a devolatilization tower, which includes a tower body, a fluid distributor located inside the tower body, and several internal components of the falling film devolatilization tower with bionic structure as described in the first embodiment. , the fluid distributor is located above the internal components of the bionic structure falling film devolatilization tower, and the support is located between the two internal components of the bionic structure falling film devolatilization tower.

[0070] Further, the length of each support is 5-1000mm, more preferably 10-200mm.

[0071] In this embodiment, the shape of the tray bodies of the inner components of the two adjacent biomimetic structure falling film devolatilization towers are differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com