TGIC efficient devolatilization and melt extrusion granulation integrated device

A melt extrusion and granulation technology, which is applied in the field of TGIC high-efficiency devolatilization and melt extrusion and granulation integrated devices, can solve the problems of low epichlorohydrin distillation efficiency, low production efficiency, powder falling off, etc., and achieve production efficiency. High, improve production efficiency, improve the effect of crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

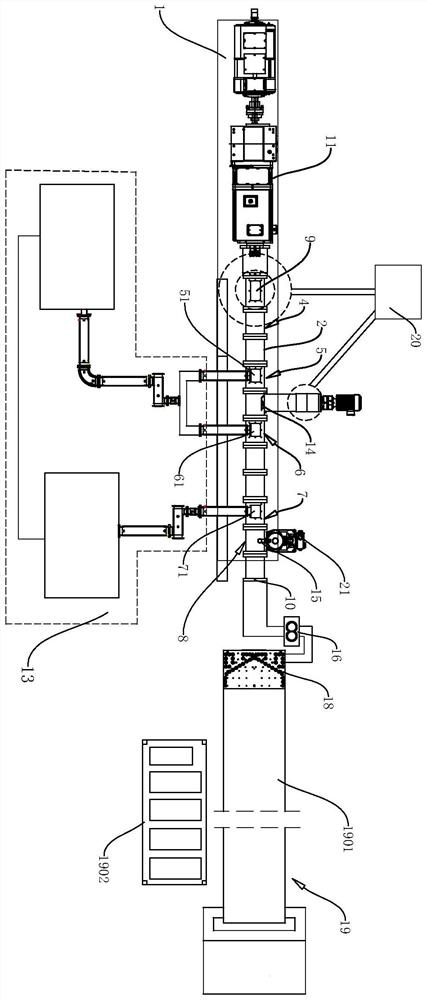

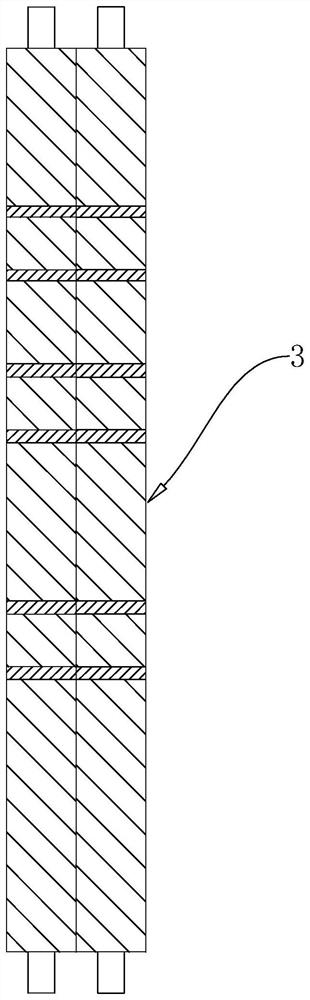

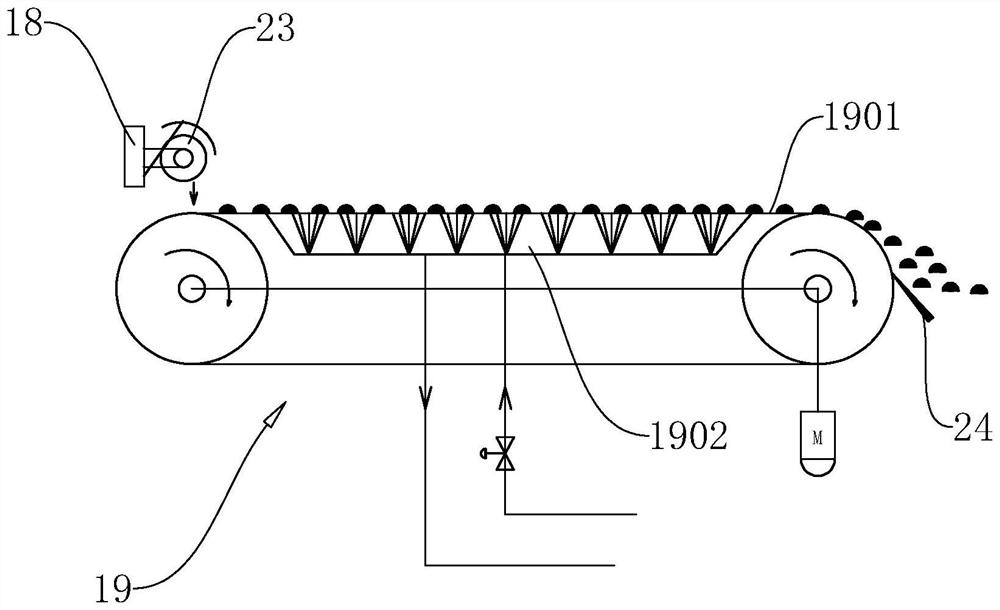

[0045] refer to figure 1 and figure 2 , this embodiment discloses a TGIC high-efficiency devolatilization and melt extrusion granulation integrated device, including a frame 1, a twin-screw extruder barrel 2 is arranged on the frame 1, and the twin-screw extruder machine One end of the cylinder 2 is provided with a main feeding port 9, and the other end is provided with a material outlet 10, wherein the main feeding port 9 is connected with a metering feeding system 20 for feeding TGIC wet powder. A pair of screw rods 3 are arranged in the barrel 2 of the twin-screw extruder, and one end of the pair of screw rods 3 is driven to rotate through the transmission mechanism 11, and the screw rod 3 is driven to rotate in the barrel 2 of the twin-screw extruder through the transmission mechanism 11. The two screws 3 can rotate in the same direction or rotate in different directions. In this embodiment, the transmission mechanism 11 drives the two screws 3 to rotate in the same dire...

Embodiment 2

[0058] refer to Figure 4 , the rest of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, a gas injection port 12 is also provided on the barrel 2 of the twin-screw extruder, and the gas injection port 12 is arranged in the second exhaust area 6 and the third exhaust area 7, inject low-boiling inert compounds, such as water, nitrogen, carbon dioxide, etc., from the gas injection port 12, and then volatilize through the third vacuum port 71 to remove the small molecular components in the material It has a carrying effect, which can improve the effect of devolatilization.

Embodiment 3

[0060] refer to Figure 5 , the rest of this embodiment is the same as that of Embodiment 2. The difference is that in this embodiment, the length-to-diameter ratio of the screw 3 of the twin-screw extruder is 36-52D, and the discharge on the barrel 2 of the twin-screw extruder is The port 10 is connected to a second-stage extruder 17 by a melt pump 16, the inlet of the melt pump 16 is connected to the discharge port 10 of the twin-screw extruder, and the outlet of the melt pump 16 is connected to the outlet of the second-stage extruder 17. The entrance is connected.

[0061] The second-stage extruder 17 can be a single-screw extruder or a twin-screw extruder. In this embodiment, the second-stage extruder 17 adopts a co-rotating twin-screw extruder. In addition, in this embodiment, the second side feeding port 15 is not opened between the third exhaust zone 7 outlets 10, the second side feeding port 15 is arranged on the barrel of the second-stage extruder 17, The second sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com