Method of producing boards

A technology of cardboard and fiber paper web, applied in the field of cardboard manufacturing, to achieve the effects of saving chemical consumption, reducing energy consumption, and improving forming consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

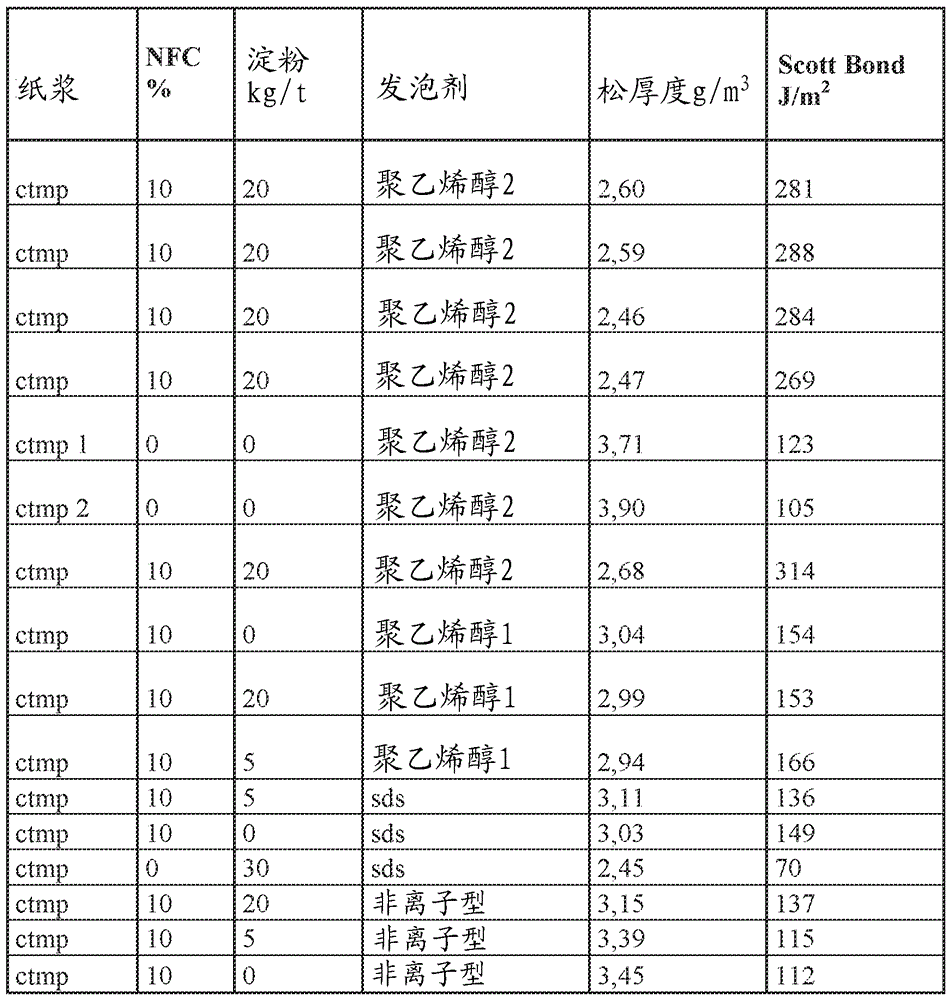

[0085] The invention has been tested under laboratory conditions. figure 2 Contains a table with bulk and Scott Bond values for the middle ply of folding boxboard obtained from the tests.

[0086] According to a preferred embodiment for manufacturing the paperboard of the invention, the fibrous material and nanocellulose mixture are mixed with a prefabricated foam made using polyvinyl alcohol. The foam typically has an air content of about 60% to 70% from which the fibrous foam is made (for example by pumping the foam through a wire). Excellent formation is achieved because in a stable foam the particles are kept at a distance and flocculation does not occur. After the web is formed, the fibrous web is dried, eg by sucking air through the web (eg using a suction slit).

[0087] Tests of different embodiments of the invention using different polyvinyl alcohol grades as blowing agents to maximize the benefits of polyvinyl alcohol have shown that, on a laboratory scale, for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com