High-strength wet strength agent for papermaking and preparation method of wet strength agent

A wet strength agent and high-strength technology, which is applied in the field of high-strength papermaking wet strength agent and its preparation, can solve the problems of poor moisture resistance and low paper strength, and achieves improved wet strength, improved contact performance, and enhanced mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

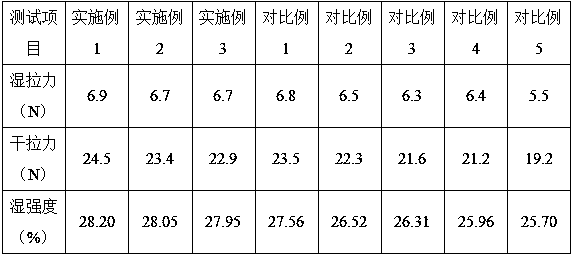

Examples

preparation example Construction

[0028] The preparation method of the reactive agent is as follows: taking p-hydroxymethyl benzaldehyde and adding citric acid and toluene in a mass ratio of 3-5:4-7, heating up to 50-60° C. and stirring and mixing for 20-50 min to obtain a mixed solution, and taking the mixed solution Add pyridine and aniline in a mass ratio of 10~20:1~3:0.5~1, heat up to 70~80°C, stir and mix for 1~3h, cool to room temperature to obtain a cooling substance, and take the cooling substance in a mass ratio of 10~20:5 ~7 Add potassium carbonate aqueous solution with a mass fraction of 25%, stir and mix at 20~25°C for 20~30min, adjust the pH to 2~3, filter, and take the precipitate, wash and dry with water to obtain the reactive agent.

[0029]The preparation method of the wet strength enhancing active agent is as follows: taking D-glucuronic acid in a mass ratio of 2~5:10~20, adding acetic acid-sodium acetate buffer of pH 6.0, stirring and mixing for 20~30min, to obtain a mixed solution a, Under ...

Embodiment 1

[0043] The preparation method of the reactive agent is as follows: taking p-hydroxymethylbenzaldehyde in a mass ratio of 3:4, adding citric acid and toluene, heating to 50° C., stirring and mixing for 20 minutes, to obtain a mixed solution, and taking the mixed solution in a mass ratio of 10:1:0.5 Add pyridine and aniline, heat up to 70 °C, stir and mix for 1 h, cool to room temperature to obtain a cooled product, take the cooled product and add 25% potassium carbonate aqueous solution in a mass ratio of 10:5, stir and mix at 20 °C for 20 minutes, adjust pH To 2, filter, take the precipitate, wash and dry with water to obtain the reactive agent.

[0044] The preparation method of the wet strength enhancing active agent is as follows: taking D-glucuronic acid in a mass ratio of 2:10, adding acetic acid-sodium acetate buffer with pH 6.0, stirring and mixing for 20 minutes, to obtain a mixed solution a, taking and mixing under aseptic conditions Liquid a was added with β-glucosid...

Embodiment 2

[0058] The preparation method of the reactive agent is as follows: take p-hydroxymethyl benzaldehyde, add citric acid and toluene in a mass ratio of 4:6, heat up to 55°C and stir and mix for 35 minutes to obtain a mixed solution, and take the mixed solution in a mass ratio of 15:2:0.7 Add pyridine and aniline, heat up to 75°C, stir and mix for 2 hours, cool to room temperature to obtain a cooling product, take the cooling product and add 25% potassium carbonate aqueous solution in a mass ratio of 15:6, stir and mix at 22 °C for 25 minutes, adjust pH to 2.5, filter, wash and dry the precipitate with water to obtain the reactive agent.

[0059] The preparation method of the wet strength enhancing active agent is as follows: taking D-glucuronic acid in a mass ratio of 4:15, adding acetic acid-sodium acetate buffer with pH 6.0, stirring and mixing for 25min, to obtain a mixed solution a, taking and mixing under aseptic conditions Liquid a was added with β-glucosidase and laccase i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com