Preparation method of sealing element for hydraulic system

A technology for hydraulic systems and seals, which is applied in the field of preparation of seals for hydraulic systems, can solve problems such as failure to be clearly identified, storage of seals, improper maintenance, and excessive initial compression of seals. Effects of aging reaction progress, low airtightness, low aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. The synthetic method of modifying agent, synthetic route is:

[0043]

[0044] Take by weighing 4-aminodiphenylamine-2-sulfonic acid and butylene oxide in a molar ratio of 1:1.15, add dehydrated alcohol, and the consumption ratio of 4-aminodiphenylamine-2-sulfonic acid and dehydrated alcohol is 1g: 10mL, after stirring evenly, in N 2 Protected, reacted at 110°C for 6 hours, distilled off ethanol and unreacted butylene oxide under reduced pressure, and dried to obtain a modifier with a yield of 84.6%.

[0045] 1 H NMR (CDCl 3,600MHz)δ:7.41(2H,Ph-H),7.28(2H,Ph-H),6.97(H,Ph-H),6.49-6.83(3H,Ph-H),4.57(1H,CH), 4.10(2H,NH),3.84(1H,-OH),2.74(2H,CH 2 ),2.45(1H,CH),2.13(1H,-OH),1.91(2H,CH 2 ).ESI-MS m / z: 351.07 ([M+Na] + ); Anal.calcd for C 16 h 18 N 2 o 5 S: C, 54.85; H, 5.20; N, 8.02, O, 22.81, S, 9.14.

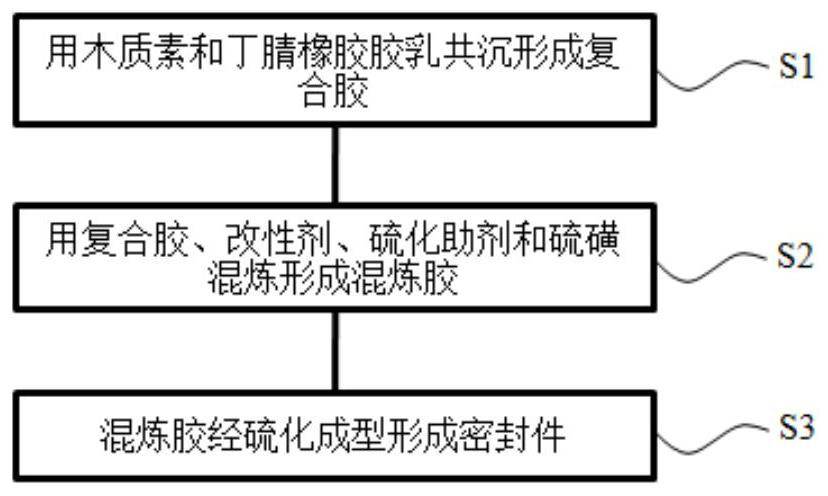

[0046] 2. A method for preparing seals for hydraulic systems, including:

[0047] S1: Prepare lignin into 12wt% lignin alkali solution with a pH of 12, then...

Embodiment 2

[0052] 1. The synthetic method of modifier,

[0053] Take by weighing 4-aminodiphenylamine-2-sulfonic acid and butylene oxide in a molar ratio of 1:1.2, add dehydrated alcohol, and the consumption ratio of 4-aminodiphenylamine-2-sulfonic acid and dehydrated alcohol is 1g: 11mL, after stirring evenly, in N 2 Protected, reacted at 115°C for 5 hours, distilled off ethanol and unreacted butylene oxide under reduced pressure, and dried to obtain a modifier with a yield of 83.7%.

[0054] 2. A method for preparing seals for hydraulic systems, including:

[0055] S1: Prepare lignin into 8wt% lignin alkali solution with a pH of 11, then slowly add lignin solution into diluted nitrile latex, stir well, flocculate with 4% dilute hydrochloric acid, and wash the flocculated gel Finally, air-dry at 70°C to constant weight to obtain composite glue;

[0056] S2: Mix the composite rubber and modifier in a 90°C internal mixer for 15 minutes, then add vulcanization aids and sulfur, and conti...

Embodiment 3

[0060] 1. The synthetic method of modifying agent is with embodiment 1.

[0061] 2. A method for preparing seals for hydraulic systems, including:

[0062] S1: Prepare lignin into 12wt% lignin alkali solution with a pH of 12, then slowly add the lignin solution into the diluted nitrile latex, stir well and flocculate with 5% dilute hydrochloric acid, and the flocculated gel is washed Finally, air-dry at 65°C to constant weight to obtain a composite glue;

[0063] S2: Mix the composite rubber and modifier in an internal mixer at 85°C for 10 minutes, then add vulcanization aids and sulfur, and continue mixing for 8 minutes to form a mixed rubber;

[0064] S3: Vulcanize the mixed rubber in a flat vulcanizing machine at a temperature of 152 °C and a pressure of 0.37 MPa for 45 minutes, trim the edges, and cool to room temperature to form a seal.

[0065] The trade mark of above-mentioned nitrile rubber is Perbunan 3945, and acrylonitrile content is 39wt%, Mooney viscosity is 45;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com