A kind of graphite phase carbon nitride/epoxy resin corrosion-resistant coating and its preparation method and application

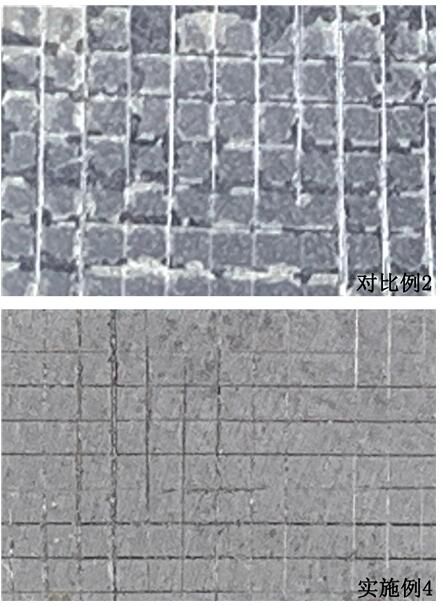

A graphite phase carbon nitride, epoxy resin technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of corrosion resistance, poor durability, micropores, etc., and achieve improved adhesion and filler dispersibility. Good, paint protection rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

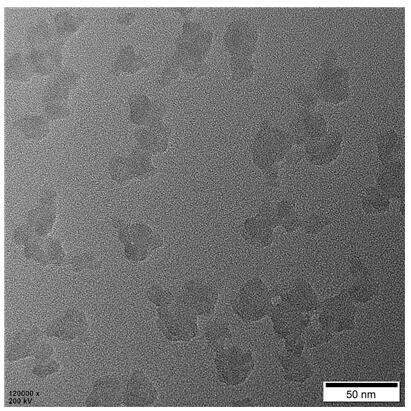

[0034] Example 1 (1 wt.%g-C 3 N 4 / EP)

[0035] A preparation method of a graphite-like carbon nitride / epoxy resin corrosion-resistant coating, comprising the following steps: first preparing a bulk phase carbon nitride, then preparing a graphite-like carbon nitride, and preparing the prepared graphite-like carbon nitride g-C 3 N 4 Nanoparticles are dispersed in acetone, ultrasonically dispersed, then epoxy resin and solvents (n-butanol and xylene) are sequentially added to the dispersion, and ultrasonic dispersion is continued to obtain a uniform mixed solution, then the mixed solution is stirred and heated to remove excess Acetone, and then add the curing agent solution to the above mixture and stir for 10-30 minutes; put it in a vacuum drying oven at room temperature for 10-20 minutes to remove the air bubbles in the mixture; obtain a graphite-like carbon nitride / epoxy resin corrosion-resistant coating. Finally, the treated mixture is coated on the surface of the metal ...

Embodiment 2

[0040] Example 2 (1.5 wt.%g-C 3 N 4 / EP)

[0041] This embodiment provides a preparation method of graphite-like carbon nitride / epoxy resin corrosion-resistant coating, the specific steps are as follows:

[0042] The preparation process of the bulk phase carbon nitride and the preparation process of the graphitic phase carbon nitride are the same as in Example 1.

[0043] Graphite phase carbon nitride g-C 3 N 4 Take 15mg of nanoparticles and disperse them in 4g of acetone for 20-30min to obtain a dispersion liquid, then add 1g of epoxy resin and 1g of solvent (n-butanol and xylene) into the dispersion liquid, and ultrasonically disperse for 30-60min to obtain a uniform Mixed solution, then stirred and heated the mixed solution to remove excess acetone; then added 6 mg of curing agent solution to the above mixture and stirred for 10-30 minutes; put it in a vacuum drying oven at room temperature for 10-15 minutes to remove air bubbles in the mixture. Finally, apply the trea...

Embodiment 3

[0044] Example 3 (2 wt.%g-C 3 N 4 / EP)

[0045] This embodiment provides a preparation method of graphite-like carbon nitride / epoxy resin corrosion-resistant coating, the specific steps are as follows:

[0046] The preparation process of the bulk phase carbon nitride and the preparation process of the graphitic phase carbon nitride are the same as in Example 1.

[0047] Graphite phase carbon nitride g-C 3 N 4 Take 20 mg of nanoparticles and disperse them in 4 g of acetone for 20-30 minutes to obtain a dispersion liquid, then add 1 g part of epoxy resin and 1 g part of solvent (n-butanol and xylene) into the dispersion liquid, and ultrasonically disperse for 30-60 min to obtain a uniform Consistent mixed solution, then stirred and heated the mixed solution to remove excess acetone; then added 6mg curing agent solution to the above mixture and stirred for 10-30min; put it in a vacuum drying oven at room temperature for 10-15min to remove the air bubbles in the mixture. Fina...

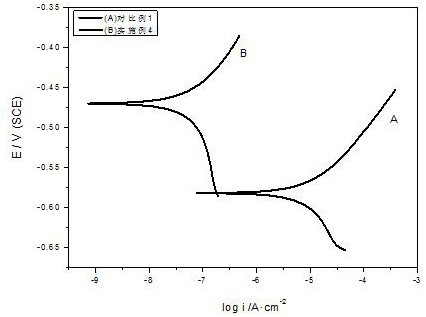

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com