Oil resistant stator rubber used for positive displacement motor drill with equal wall thickness

A screw drilling tool and oil stator technology, which is applied in the field of oil-resistant stator rubber materials for thick wall screw drilling tools and its preparation, can solve the problems of shortened drilling tool life, stator rubber failure, and rubber Mooney viscosity increase. Long burning time, good oil resistance and low Mooney viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

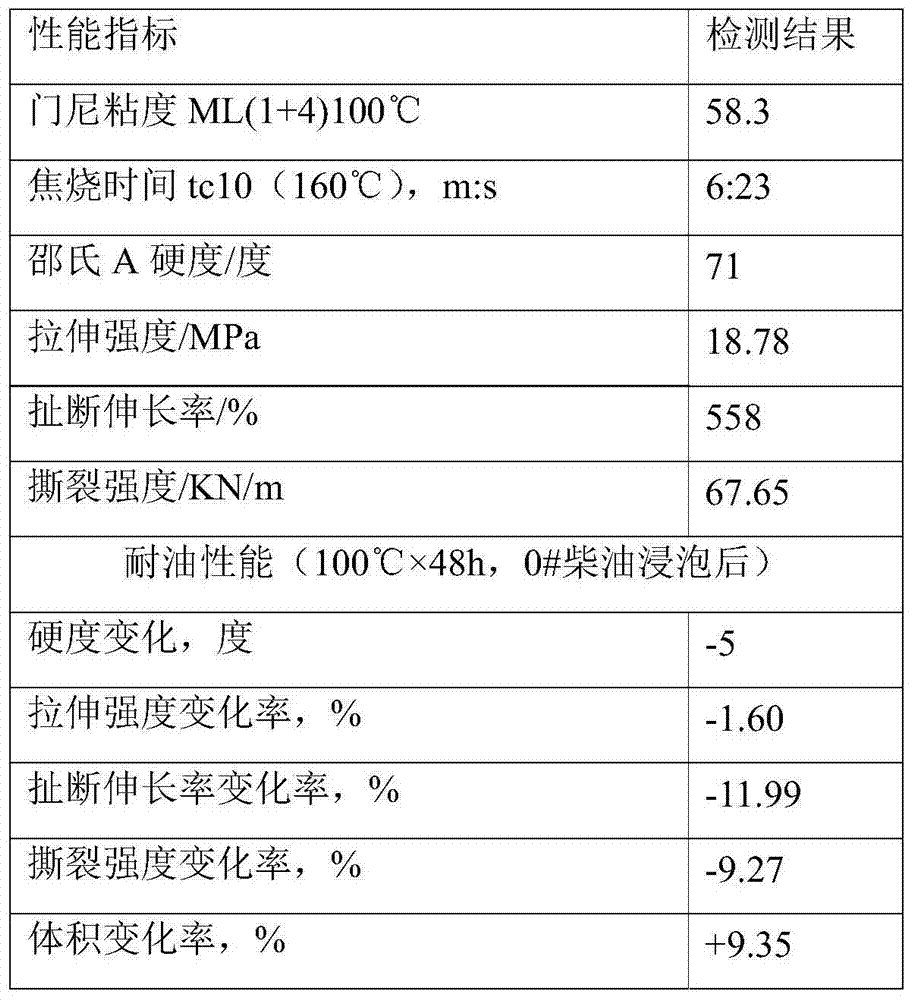

Embodiment 1

[0029] An oil-resistant stator rubber for equal wall thickness screw drilling tools, which is made of the following raw materials in parts by mass: 100 parts of nitrile rubber N230S, 5 parts of zinc oxide, 1 part of stearic acid, 60 parts of carbon black N330, plasticizer DINP 15 parts, anti-aging agent RD 3 parts, anti-aging agent 40202 parts, sulfur 2 parts, accelerator DM 1 part, anti-scorch agent PVI 0.5 parts.

[0030] The preparation method of the oil-resistant stator rubber for the equal-wall thickness screw drilling tool includes the following steps:

[0031] 1) Weigh raw materials according to the above-mentioned ratio of parts by mass, including nitrile rubber, zinc oxide, stearic acid, carbon black, plasticizer, anti-aging agent, vulcanizing agent, accelerator, anti-scorch agent;

[0032] 2) Put nitrile rubber in a kneader for 120-150 seconds, add zinc oxide, stearic acid, anti-aging agent, vulcanizing agent and mix for 90-120 seconds, then add 1 / 2 of carbon black a...

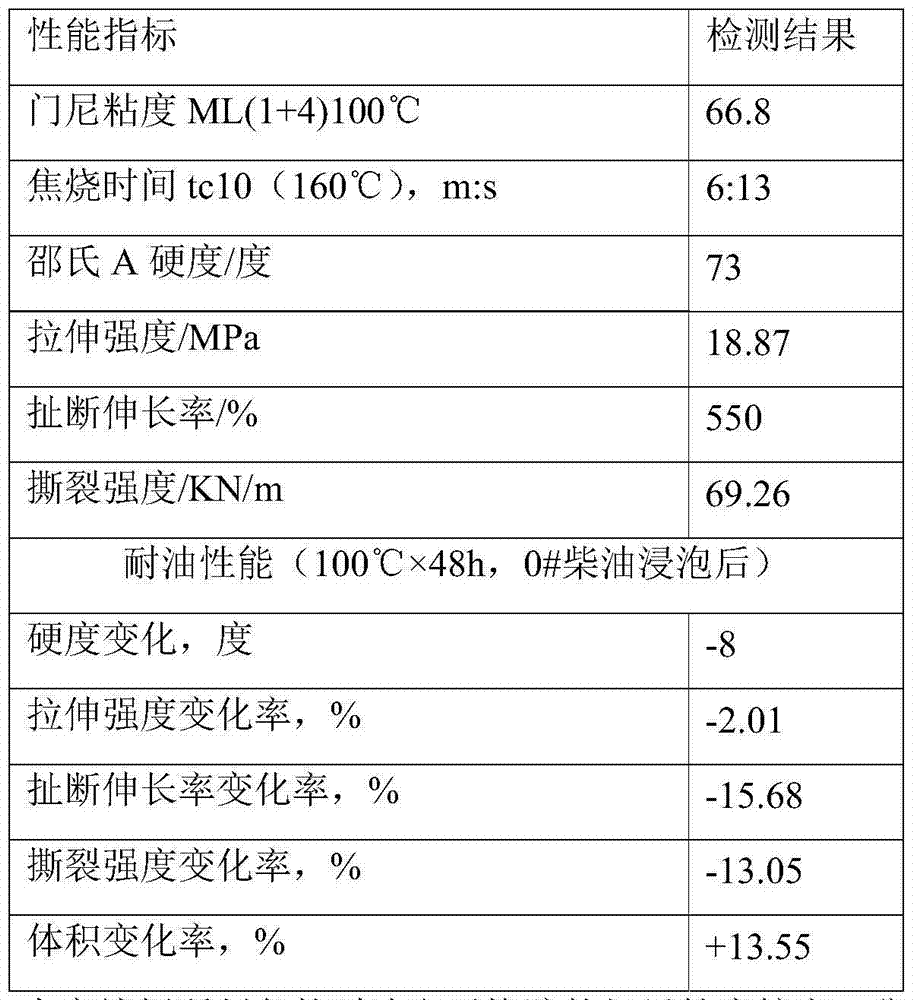

Embodiment 2

[0040] An oil-resistant stator rubber for screw drilling tools with equal wall thickness, which is made of the following raw materials in parts by mass: 100 parts of nitrile rubber NBR3606, 5 parts of zinc oxide, 1 part of stearic acid, 40 parts of carbon black N33040 parts, and 20 parts of carbon black N55020 , plasticizer TP-9510 parts, anti-aging agent 4010NA 3 parts, anti-aging agent 40202 parts, sulfur 2 parts, accelerator CZ 1 part, anti-scorch agent PVI 0.5 parts.

[0041] The preparation method of the oil-resistant stator rubber for the equal-wall thickness screw drilling tool includes the following steps:

[0042] 1) Weigh raw materials according to the above-mentioned ratio of parts by mass, including nitrile rubber, zinc oxide, stearic acid, carbon black, plasticizer, anti-aging agent, vulcanizing agent, accelerator, anti-scorch agent;

[0043] 2) Put nitrile rubber in a kneader for 130 seconds, add zinc oxide, stearic acid, anti-aging agent, vulcanizing agent and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com