Semiautomatic egg candler

A semi-automatic technology for illuminating eggs, applied in the application, poultry industry, animal husbandry, etc., can solve the problems of large damage to embryonic eggs, long time to illuminate eggs, and many damage to embryonic eggs, etc., to achieve fast egg imaging and easy operation. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

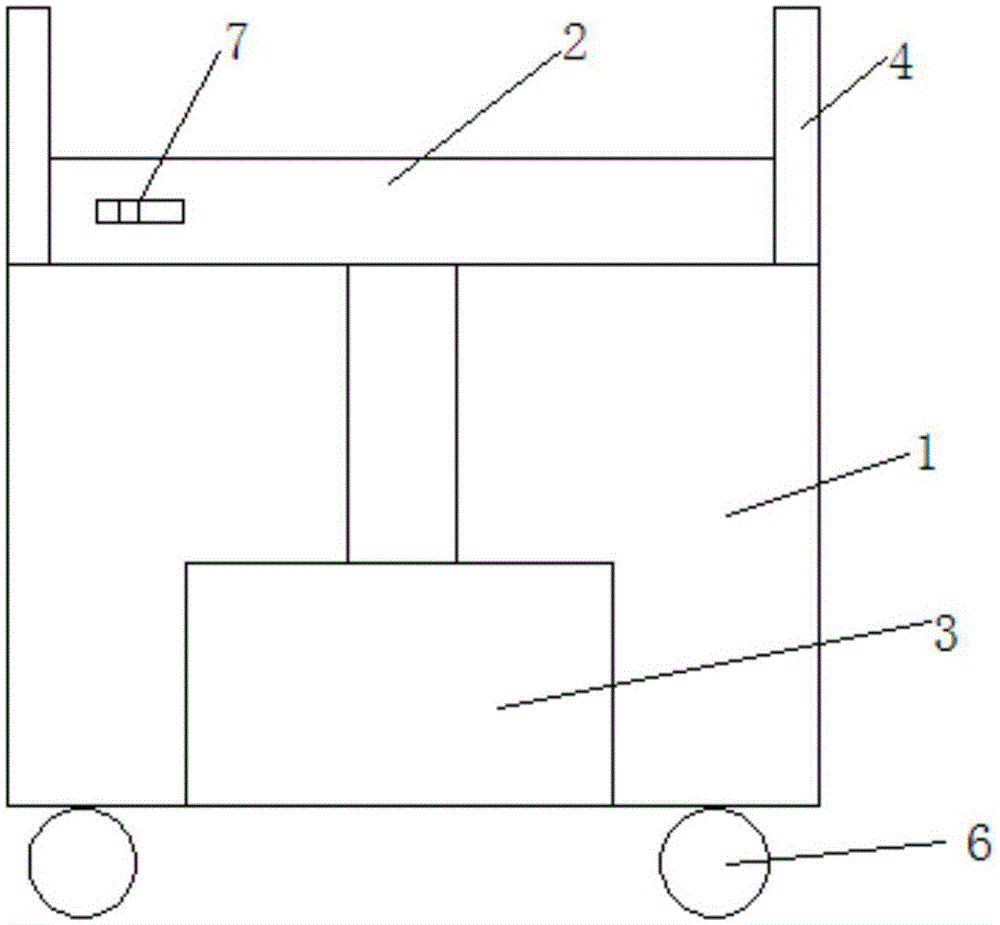

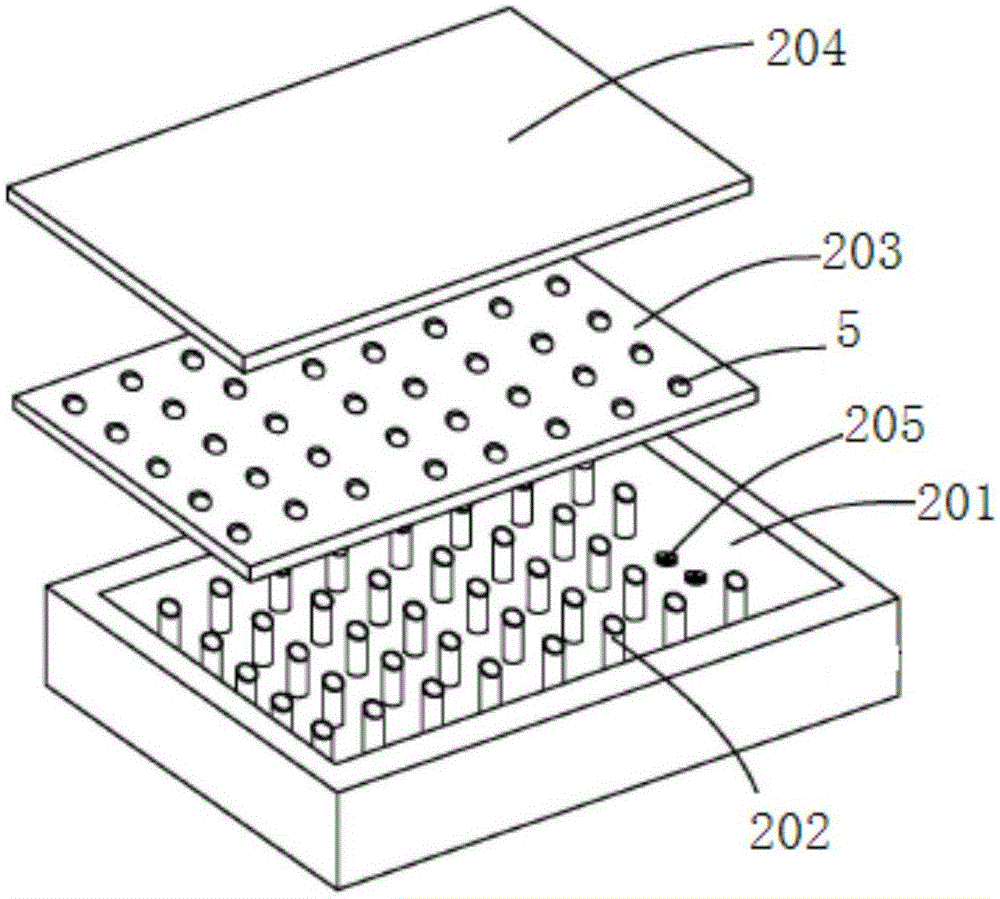

[0014] See attached figure 1 And attached figure 2 , a semi-automatic egg canister, comprising a frame body 1 and a light box 2 arranged above the frame body 1, an electric air pump 3 is arranged below the light box 2, and the electric light air pump 3 is installed on the frame body 1, and the light box 2 is two A guide plate 4 is provided on the side, and a lamp panel 201, a spotlight cover 202, a fixing plate 203, and a glass plate 204 are sequentially arranged in the light box 2 from bottom to top, and lighting lamps are arranged on the lamp panel 201 according to the rule of laying eggs on egg trays. 205, the lighting lamp is an LED lamp, each lighting lamp 205 is provided with a spotlight cover 202, the fixing plate 203 is provided with a through hole 5 corresponding to the lighting lamp 205, and a glass plate 204 is provided above the fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com