Multi-station cooperative operation egg embryo sorting device

A sorting device, multi-station technology, applied in poultry industry, animal husbandry, transportation and packaging, etc., can solve the problems of long sorting method, reduce production efficiency, increase labor cost, etc., and achieve fast egg-picking speed , the effect of improving production efficiency and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

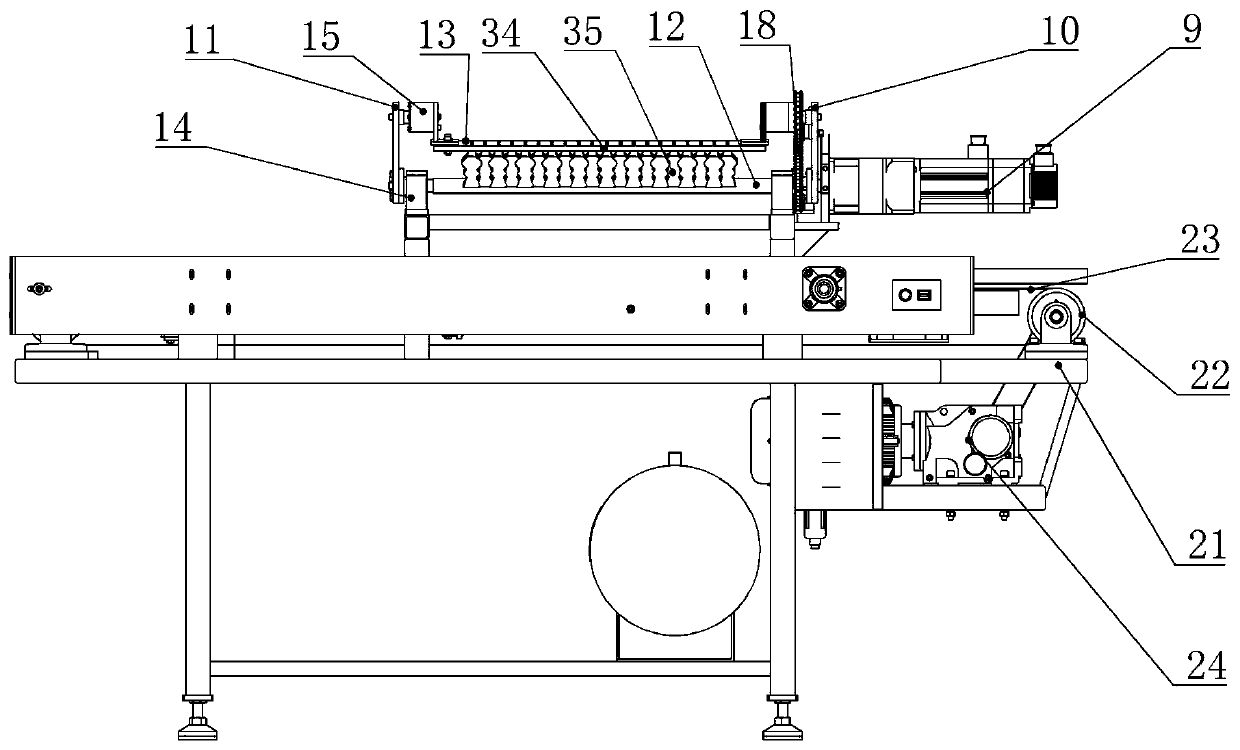

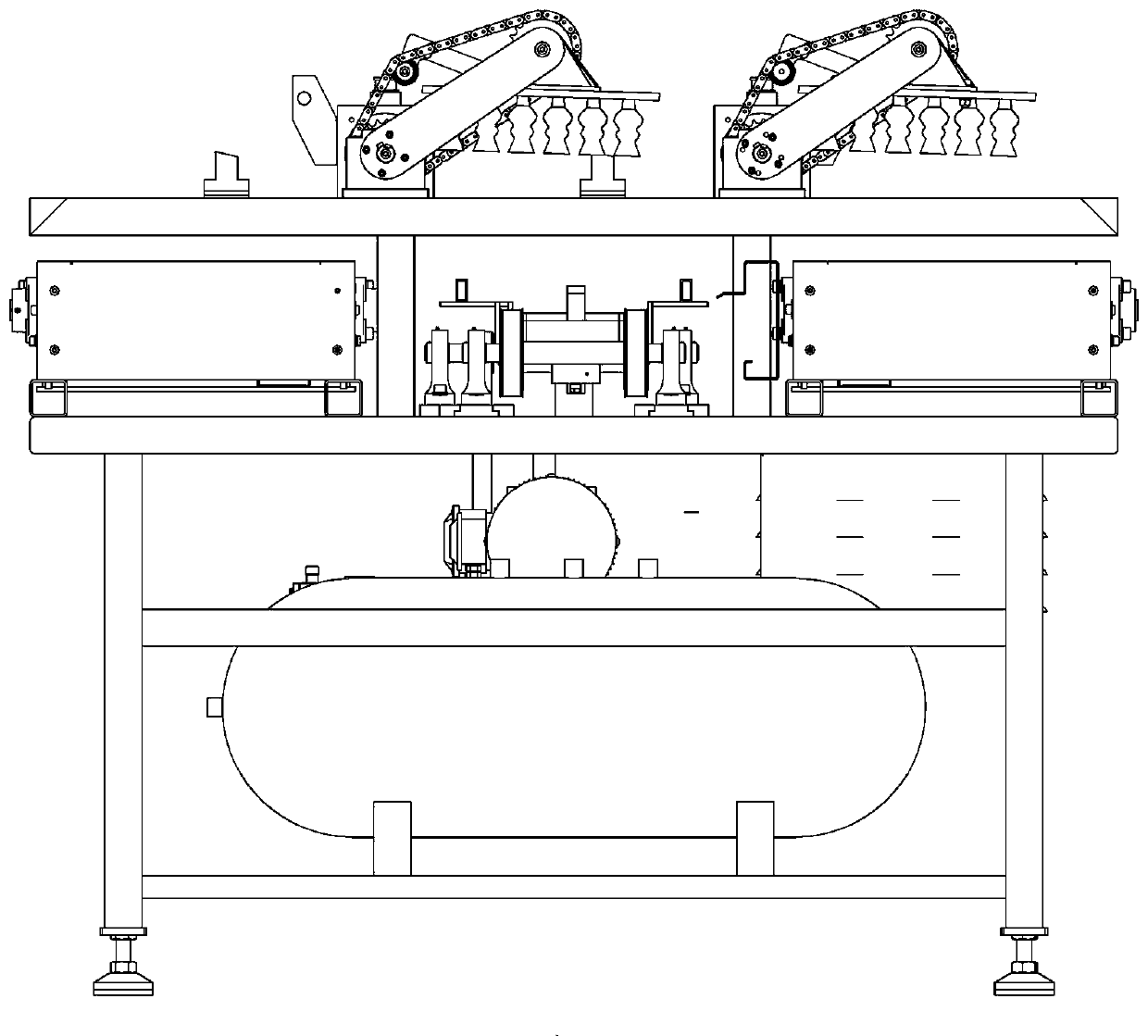

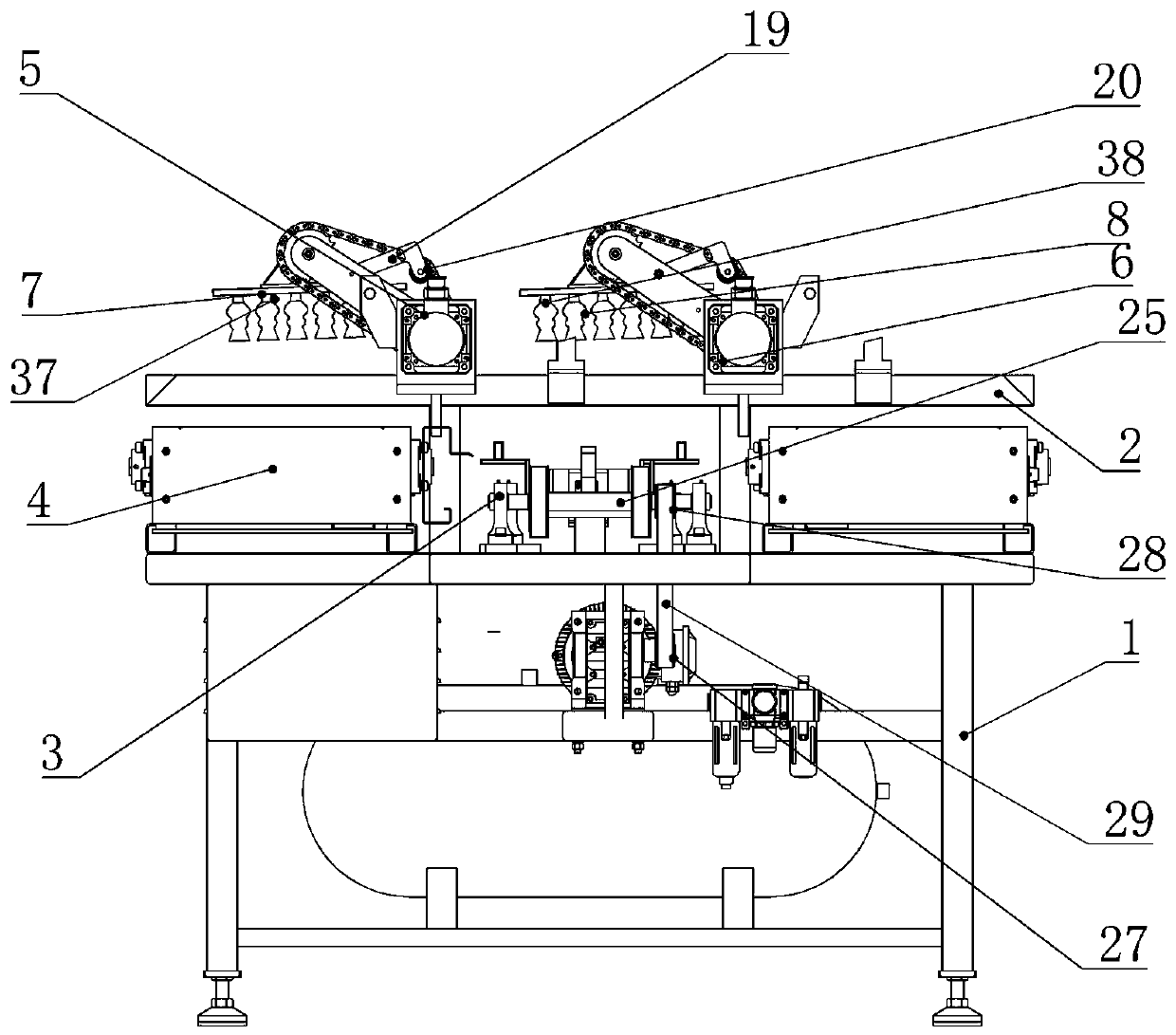

[0016] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the front view, left view, right view and top view of the egg embryo sorting device for multi-station collaborative operation are given respectively. A multi-station collaborative egg embryo sorting device consists of a lower bracket 1, an upper bracket 2, an egg embryo Conveying device 3, conveyor belt conveyor 4, first swing arm device 5, second swing arm device 6, first vacuum sorting device 7 and second vacuum sorting device 8 are combined; lower bracket 1 and upper bracket 2 are The welded frame, the upper bracket 2 is installed on the lower bracket 1; the egg embryo transfer device 3 is installed in the center on the lower bracket 1, and the transmission direction of the timing belt is the same as the length direction of the lower bracket, and the egg embryo transfer device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com