Manufacturing method of ganoderme luisant rice

A production method and rice technology, applied in the fields of botanical equipment and methods, food preparation, horticulture, etc., can solve the problems of no solution, low natural parasitic rate of Ganoderma lucidum, limited wild resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

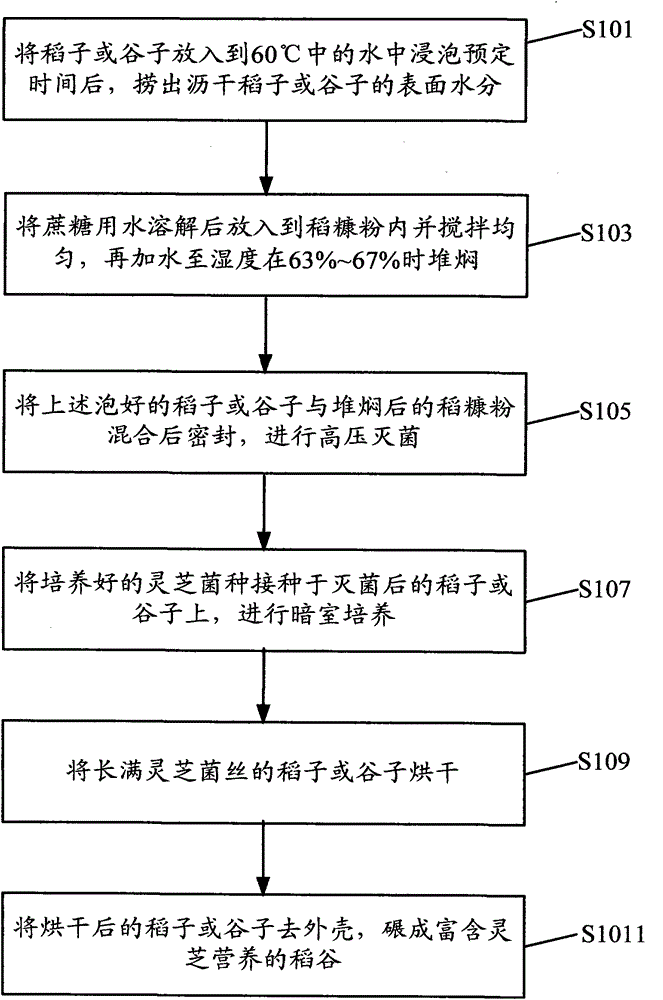

Image

Examples

Embodiment 1

[0043] Embodiment one: the preparation method of Ganoderma lucidum millet

[0044] Weigh 83% of the millet in proportion and soak in warm water at 60 degrees Celsius for 8 hours, remove and drain the surface water

[0045] Weigh 15% rice bran powder and 1% sucrose (or brown sugar) in proportion 10 hours in advance, dissolve the sucrose (or brown sugar) in water and mix in the rice bran powder, add water to adjust the humidity to 65% and stack and stew.

[0046] Mix the soaked millet and pre-wet rice bran powder evenly, put it into a clean glass bottle, seal it and put it in an autoclave, and keep the temperature at 128 degrees Celsius for 2 hours.

[0047] Take 1% of the ganoderma lucidum strain and inoculate it on the sterilized millet millet, place it in a dark environment at 22-25 degrees Celsius and cultivate it for 35-40 days to fill the bottle with the strain.

[0048] Put the millet that is covered with ganoderma lucidum mycelia on the dryer, set the temperature at 55 ...

Embodiment 2

[0050] Embodiment two: the preparation method of Ganoderma lucidum sorghum rice

[0051] Weigh 80% sorghum in proportion, put it into warm water at 60 degrees Celsius and soak for 15 hours, remove and drain the surface water

[0052] Weigh 18% rice bran powder and 1% sucrose (brown sugar) in proportion 10 hours in advance, dissolve the sucrose (brown sugar) in water and mix it into the rice bran powder, add water to adjust the humidity to 66% and stew.

[0053] Mix the soaked sorghum with the pre-wet rice bran powder evenly, put it into a clean glass bottle, seal it and put it in an autoclave, and keep the temperature at 128 degrees Celsius for 2 hours.

[0054] Take 1% ganoderma strains and inoculate them on the sterilized sorghum, place them in a dark environment at 22-25 degrees centigrade and cultivate them for 35-40 days to fill the bottle with strains.

[0055] Put the sorghum covered with ganoderma mycelium on the dryer, set the temperature at 55 degrees Celsius and keep...

Embodiment 3

[0057] Embodiment three: the preparation method of Ganoderma lucidum black rice

[0058] Weigh 83% of the black rice in proportion, soak it in warm water at 60 degrees Celsius for 13 hours, remove and drain the surface water

[0059] Weigh 15% rice bran powder and 1% sucrose (or brown sugar) in proportion 10 hours in advance, dissolve the sucrose (or brown sugar) in water and mix into the rice bran powder, add water to adjust the humidity to 64% and stack and stew.

[0060] Mix the soaked black rice with the pre-wet rice bran powder evenly, put it into a clean glass bottle, seal it and put it in an autoclave, and keep the temperature at 128 degrees Celsius for 2 hours.

[0061] Take 1% ganoderma lucidum strain and inoculate it on the sterilized black rice, place it in a dark environment at 22-25 degrees Celsius and cultivate it for 35-40 days to cover the strained bottle.

[0062] Put the black rice covered with ganoderma mycelium on the dryer, set the temperature at 55 degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com