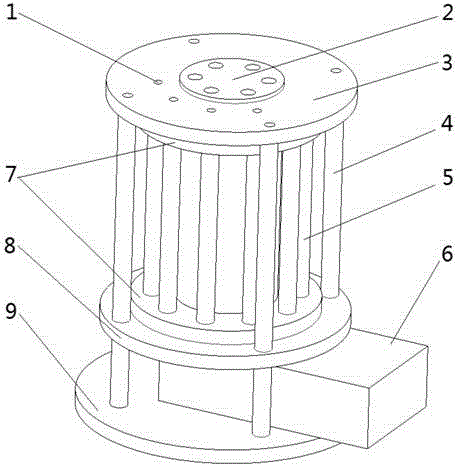

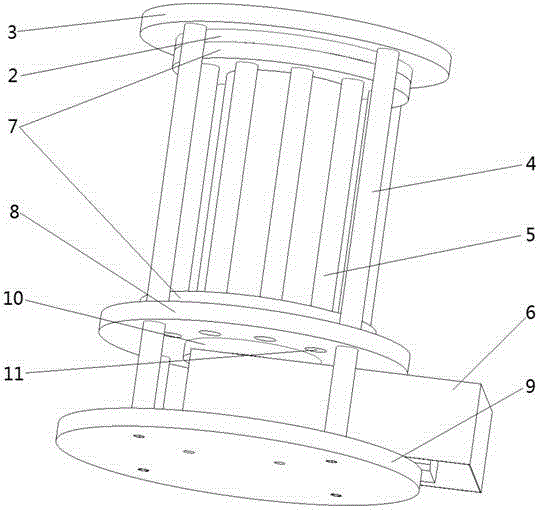

A circulating type separation column capable of continuous sample injection

A separation column and circulating technology, applied in the field of circulating continuous sampling separation column, can solve the problems such as difficult to achieve continuous separation, and achieve the effect of easy assembly or disassembly maintenance, easy manufacture, and precise rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

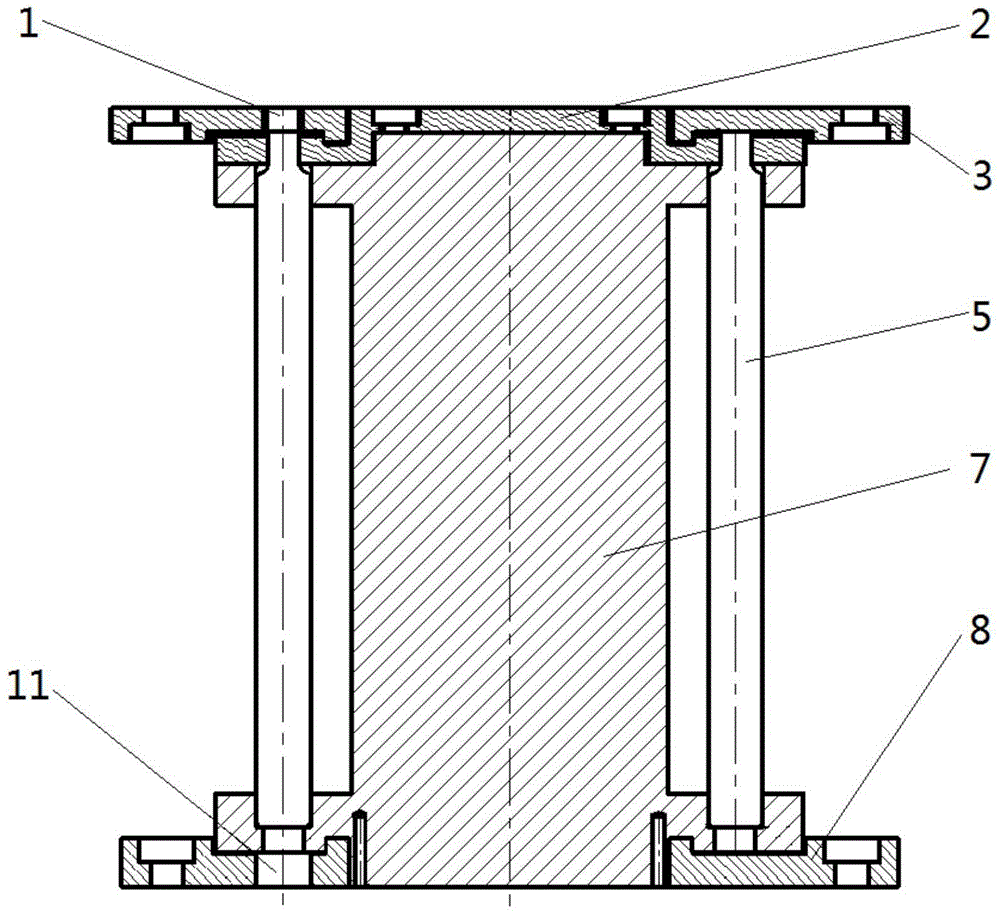

[0035] As described above, the circulating type can continuously inject samples into the separation column, the difference of this embodiment is that, as image 3 As shown, it is a cross-sectional view of a part of the structure of the cyclic continuous sampling separation column of the present invention.

[0036] combine Figure 4 As shown, it is a structural diagram of the upper platen of the circulating continuous sample injection separation column of the present invention; wherein, the upper platen 3 is a disc with the hole in the center, and the hole is a shaft hole, so that the upper platen 3 It is ring-shaped, and there is a ring-shaped groove on the inner side of the lower end surface of the upper platen 3, and there are multiple injection ports 1 in the groove; there are multiple mounting holes distributed on the outer side of the upper platen 3, which are used for fixed connection with the support column 4, The fixed connection can be a threaded connection, which is...

Embodiment 2

[0048] As mentioned above, the circulation-type separation column that can continuously inject samples is different from this embodiment in that there is an annular protrusion on the inner side of the lower end surface of the upper platen 3, and an annular groove on the outer side of the upper end surface of the glass tube cover 2, so The annular protrusion is in close contact with the annular groove.

Embodiment 3

[0050] As mentioned above, the circulation type can continuously feed the separation column, the difference of this embodiment is that the lower end surface of the glass installation cylinder 7 has an annular groove, and the inner side of the lower pressure plate 8 has an annular protrusion. The annular groove is in close contact with the annular protrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com