Punch forming system

A technology of stamping and punching, which is applied in the direction of metal processing equipment, stripping devices, manufacturing tools, etc., can solve the problems of driving safety impact, unsightly surface of plate parts, etc., and achieve the effect of avoiding reflection, beautiful appearance and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

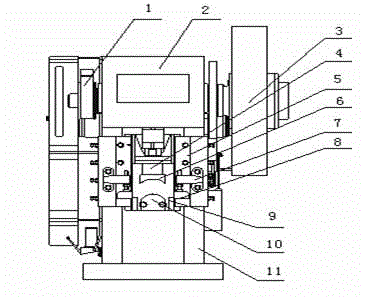

[0012] attached by figure 1 It can be seen that the present invention includes a base 11 and a nose 2, the bottom of the nose 2 is provided with a punch 4, the punch 4 is connected with the driving wheel 3, the bottom of the punch 4 is provided with an upper die 6, and the upper die 6 bottom base The relative position of 11 is provided with a lower punch 10, and the two ends of the lower punch 10 are provided with a positioning mechanism 9, and the positioning mechanism 9 is fixed on the base 11, and the positioning mechanism 9 is not in contact with the lower punch 10, and a certain gap is formed during the period. The size of the gap is set according to the shape of the arc groove to be stamped. When more arc-shaped grooves need to protrude outward, adjust the gap between the positioning mechanism and the lower punch; on the contrary, when the arc-shaped grooves need to protrude less, reduce the gap between the positioning mechanism and the lower punch. The shape of the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com