Manufacturing method of ring gauge

A manufacturing method and ring gauge technology, applied in the field of ring gauge manufacturing, can solve the problems of low production efficiency and many unqualified products, and achieve the effects of high production efficiency and pass rate, avoiding waste treatment and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

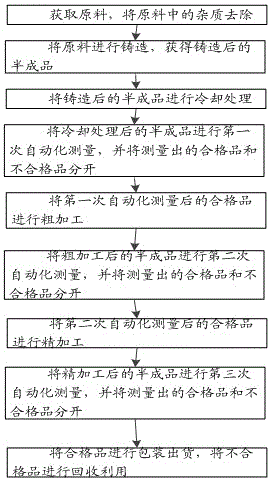

[0033] In Embodiment 1, a method for manufacturing a ring gauge is provided, please refer to figure 1 , the method includes:

[0034] Obtain raw materials and remove impurities from the raw materials;

[0035] Casting raw materials to obtain semi-finished products after casting;

[0036] Cooling the semi-finished product after casting;

[0037] Carry out the first automatic measurement of the semi-finished products after cooling treatment, and separate the measured qualified products from the unqualified products;

[0038] Roughly process the qualified products after the first automatic measurement;

[0039] Carry out the second automatic measurement of the semi-finished products after rough processing, and separate the measured qualified products from the unqualified products;

[0040] Finish the qualified products after the second automatic measurement;

[0041] Carry out the third automatic measurement of the semi-finished products after finishing, and separate the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com