A large-scale machine tool machining center with drag chain tray

A processing center and pallet technology, which is applied in the direction of large fixed members, metal processing equipment, metal processing machinery parts, etc., can solve problems such as damage to cables, equipment failure, and normal production of the factory, so as to avoid waste clogging and protect from damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

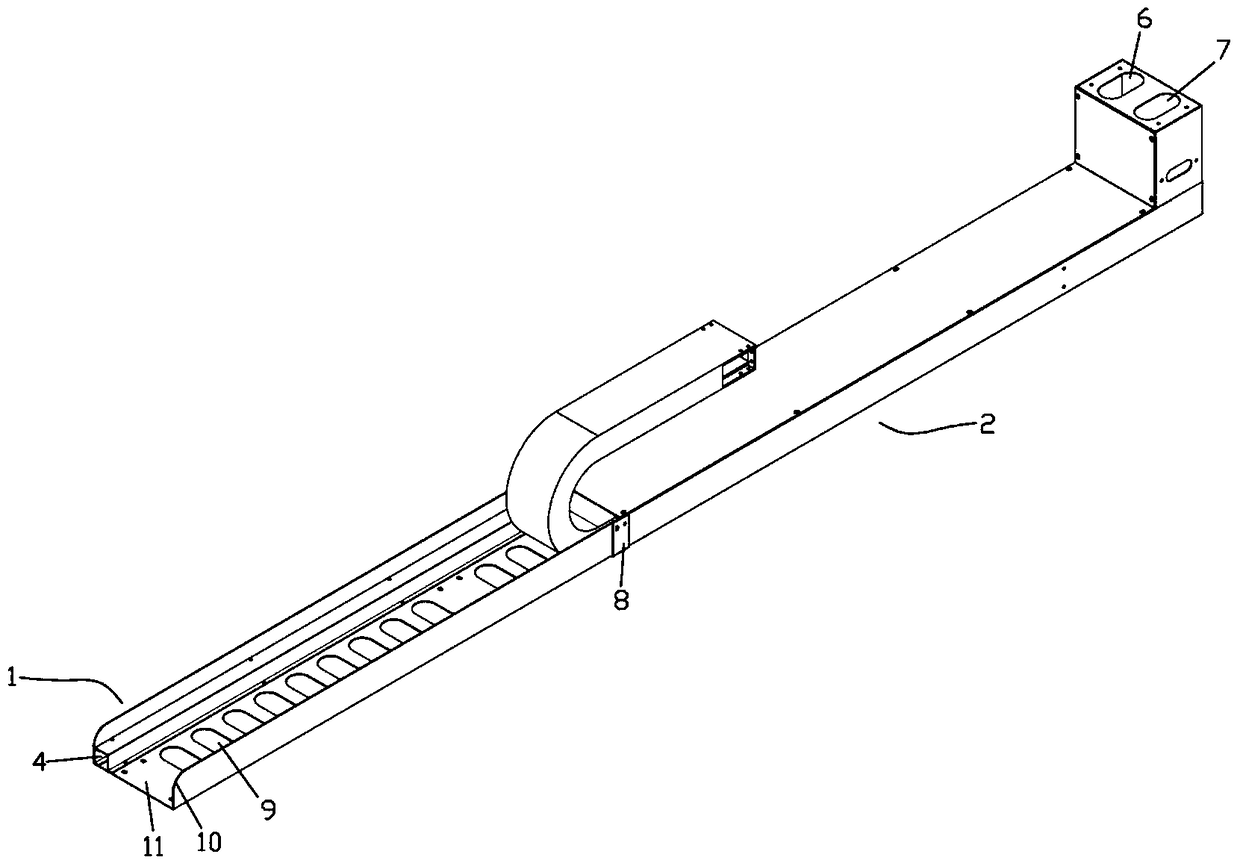

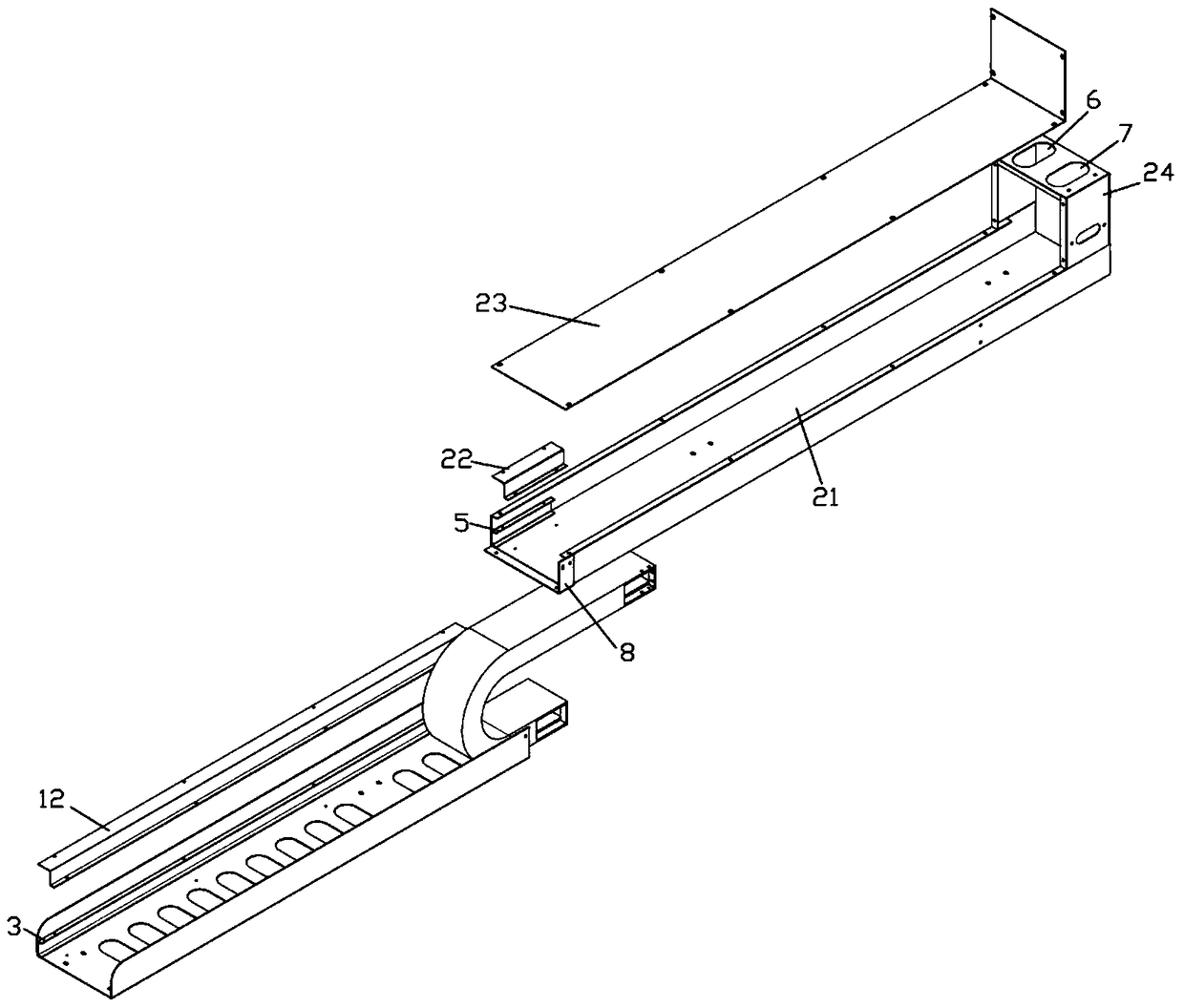

[0025] Such as Figure 1 to Figure 3 As shown, the application provides a large-scale machine tool machining center with a drag chain tray, which is suitable for the machining industry and can optimize the structure of the existing machine tool machining center, so that the function of cable classification can be realized, and the cable can be protected from damage. The effect of being damaged and avoiding waste clogging.

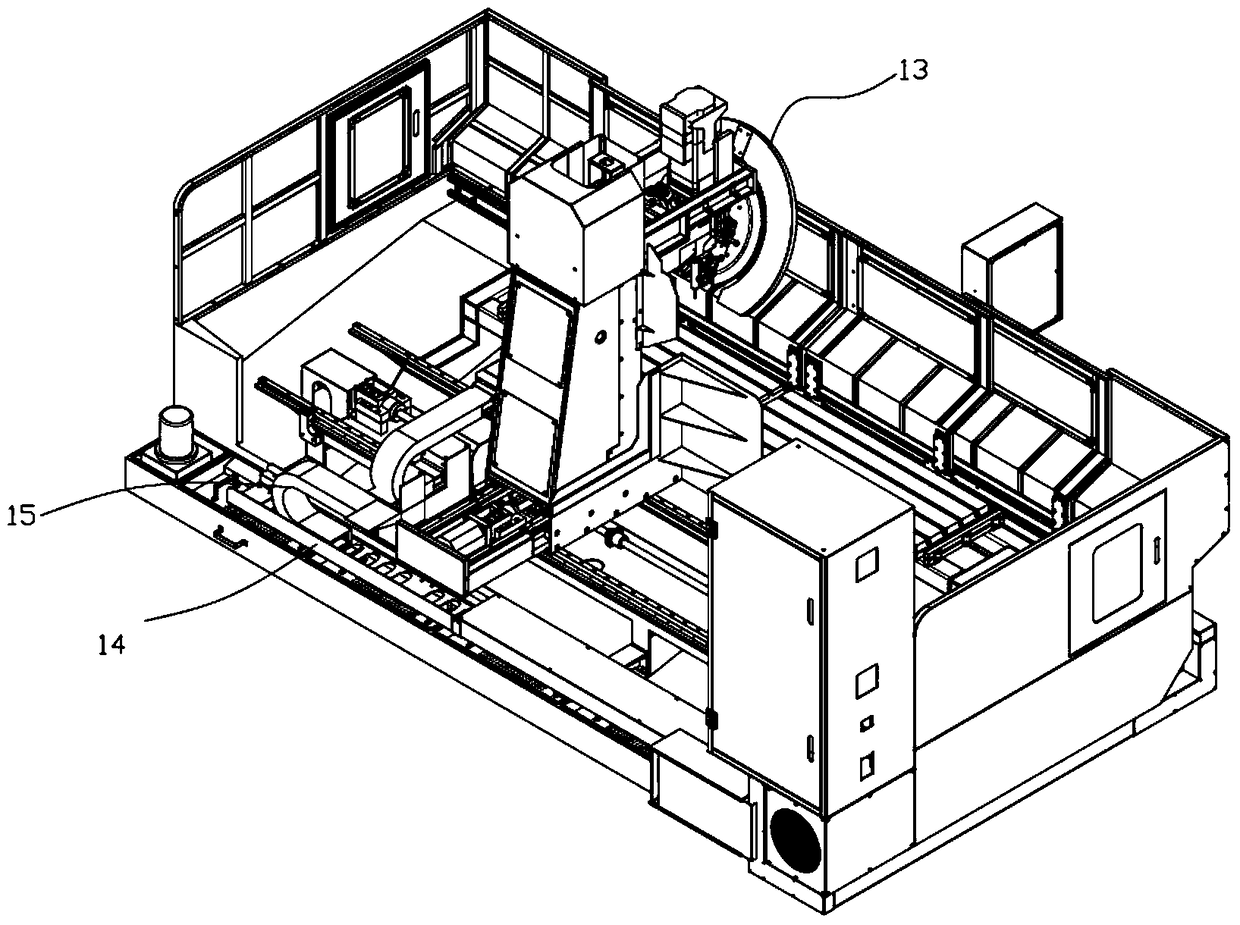

[0026] The above-mentioned large-scale machine tool machining center with a drag chain tray includes a machine tool body 13 and a drag chain tray 14. The drag chain tray 14 is arranged behind the machine tool body 13 and is connected to the machine tool body 13 through a drag chain 15. The drag chain tray 14 is mainly It consists of a first tray assembly 1 for protecting immovab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com