A sapphire substrate submerged chemical mechanical polishing method

A chemical mechanical and sapphire technology, applied in the direction of grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems of sapphire substrate sheet inlay, polishing pad degumming, bubbling, etc., to improve the polishing effect, reduce the number of scratches, avoid The effect of micro-scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A immersed chemical mechanical polishing method for a sapphire substrate sheet, the polishing method is as follows:

[0025] (1) Pretreatment

[0026] ①100 pieces of 2-inch sapphire substrates cleaned after copper polishing are attached to the hard ceramic disk with adsorption pads, 25 pieces of each hard ceramic disk are attached, and then the hard ceramic disk with the sapphire substrate is attached Soak in reverse osmosis pure water for 15 minutes. At this time, check whether there are bubbles and particles under the sapphire substrate. The hard ceramic disc 1 of the sapphire substrate must be attached;

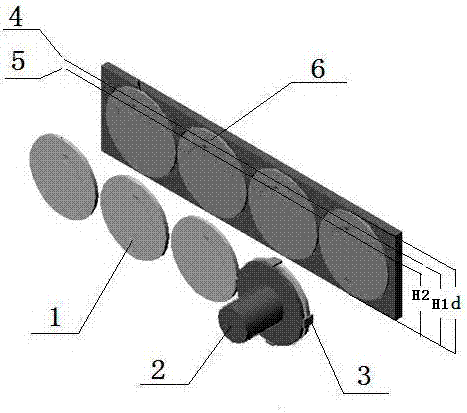

[0027] ② Mount the hard ceramic disc 1 with the sapphire substrate on the main shaft 2 of the polishing machine, and fix it with the buckle 3, and place the polishing pad on the rotating chassis 6;

[0028] ③Mix reverse osmosis pure water and silica polishing liquid to obtain a mixed liquid. The volume ratio of reverse osmosis pure water to silica polishing liquid is 5:2. T...

Embodiment 2

[0036] A immersed chemical mechanical polishing method for a sapphire substrate sheet, the polishing method is as follows:

[0037] (1) Pretreatment

[0038] ① 28 pieces of 4-inch sapphire substrates cleaned after copper polishing are attached to the hard ceramic discs with adsorption pads, each hard ceramic disc is attached to 7 pieces, and then the hard ceramic discs with sapphire substrates are attached Soak in reverse osmosis pure water for 15 minutes. At this time, check whether there are bubbles and particles under the sapphire substrate. The hard ceramic disc 1 of the sapphire substrate must be attached;

[0039] ② Mount the hard ceramic disc 1 with the sapphire substrate on the main shaft 2 of the polishing machine, and fix it with the buckle 3, and place the polishing pad on the rotating chassis 6;

[0040] ③Mix reverse osmosis pure water and silica polishing liquid to obtain a mixed liquid. The volume ratio of reverse osmosis pure water to silica polishing liquid is 5:2. The...

Embodiment 3

[0048] A immersed chemical mechanical polishing method for a sapphire substrate sheet, the polishing method is as follows:

[0049] (1) Pretreatment

[0050] ①The 72 pieces of 55 X 55 square sapphire substrates that were cleaned after copper polishing were attached to the hard ceramic discs with adsorption pads. Each hard ceramic disc was attached to 18 pieces, and then the hard sapphire substrates were attached. The ceramic disc is soaked in reverse osmosis pure water for 15 minutes. At this time, check whether there are bubbles and particles under the sapphire substrate, and the hard ceramic disc 1 with the sapphire substrate should be attached;

[0051] ② Mount the hard ceramic disc 1 with the sapphire substrate on the main shaft 2 of the polishing machine, and fix it with the buckle 3, and place the polishing pad on the rotating chassis 6;

[0052] ③Mix reverse osmosis pure water and silica polishing liquid to obtain a mixed liquid. The volume ratio of reverse osmosis pure water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com