Patents

Literature

32results about How to "Low number of scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Abrasive grain CeO2 for chemical and mechanical buffing and method for preparing same

ActiveCN101284952AReduce surface roughnessImprove flatnessPigmenting treatmentSemiconductor/solid-state device manufacturingCrystal systemInorganic salts

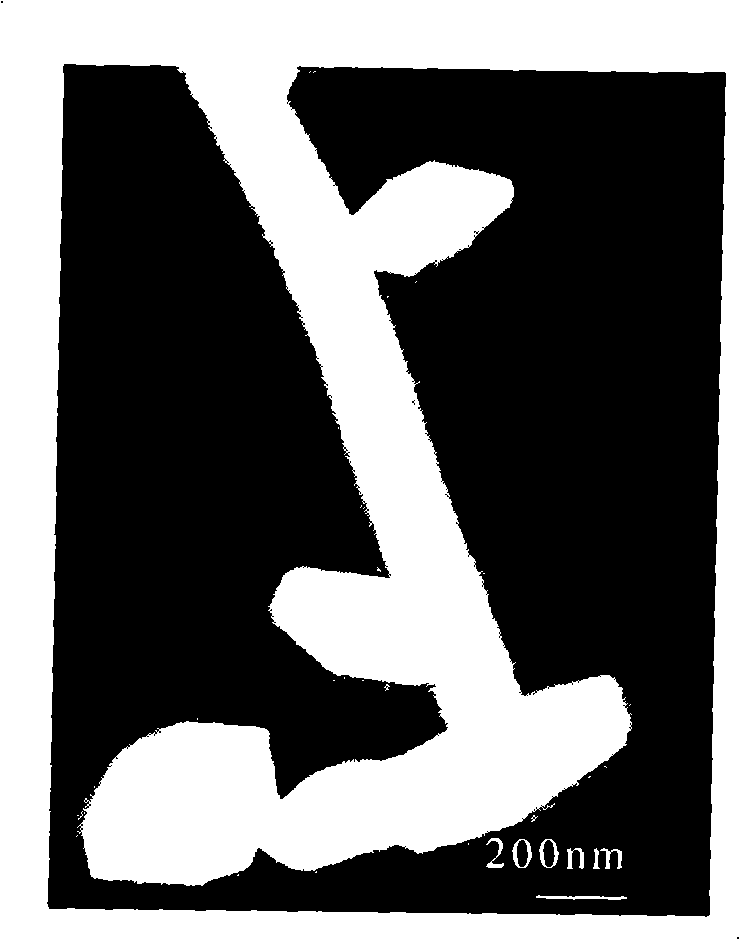

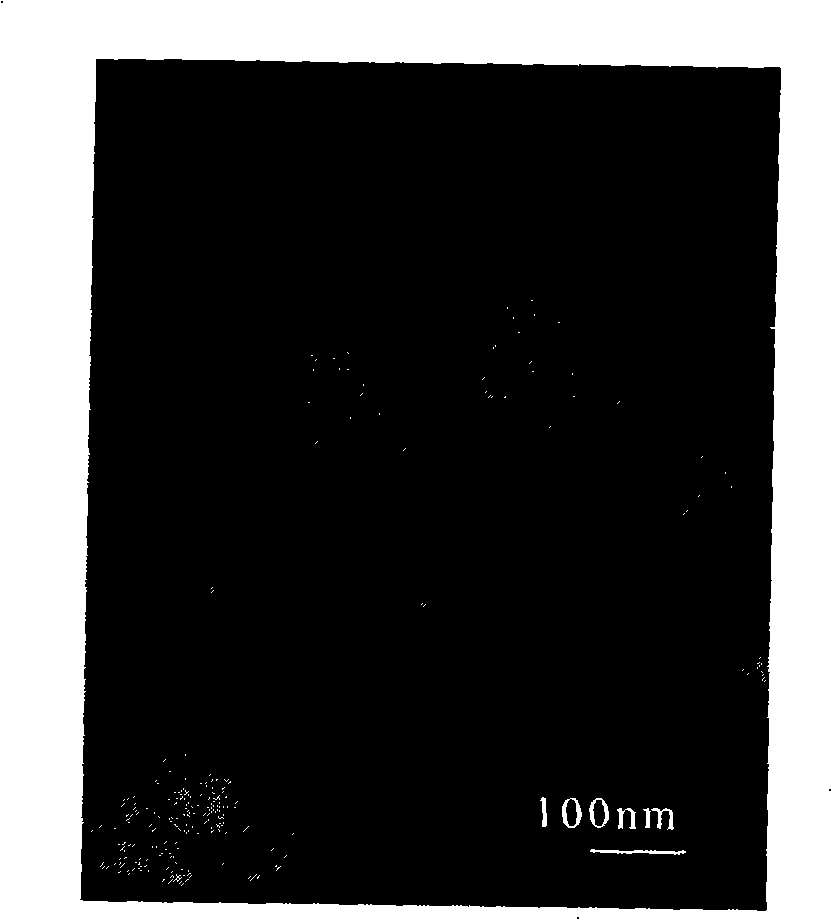

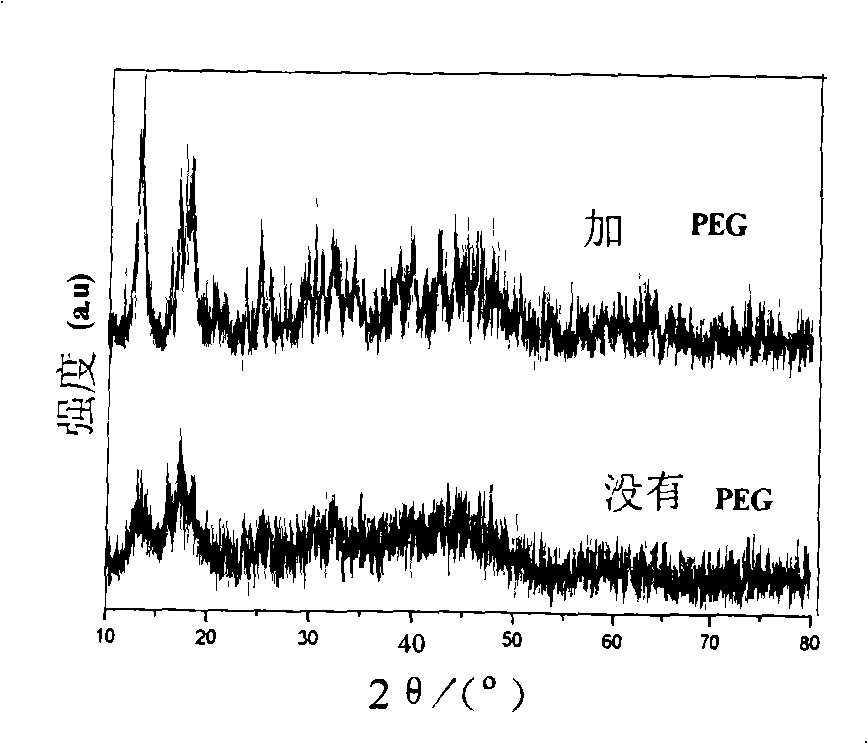

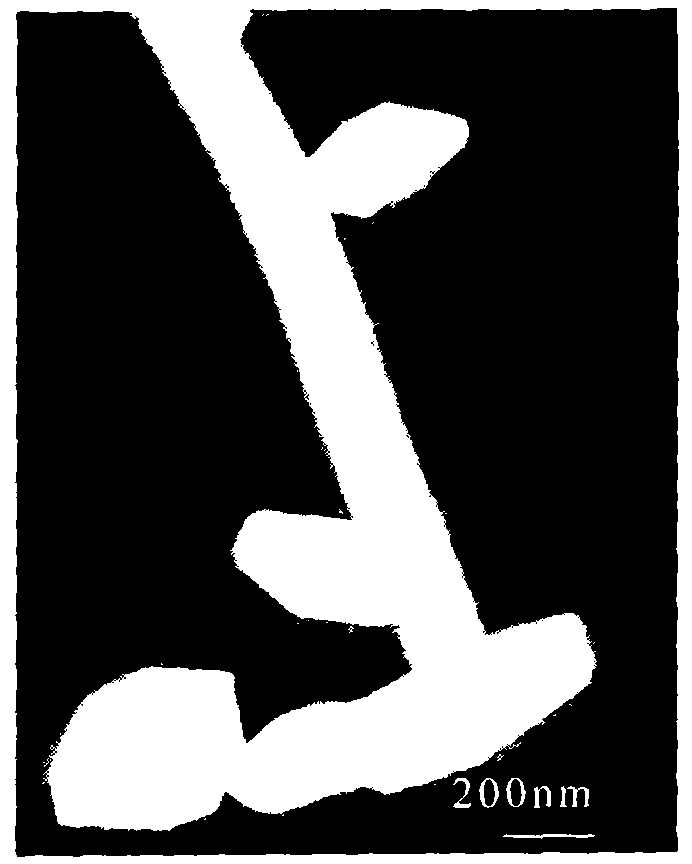

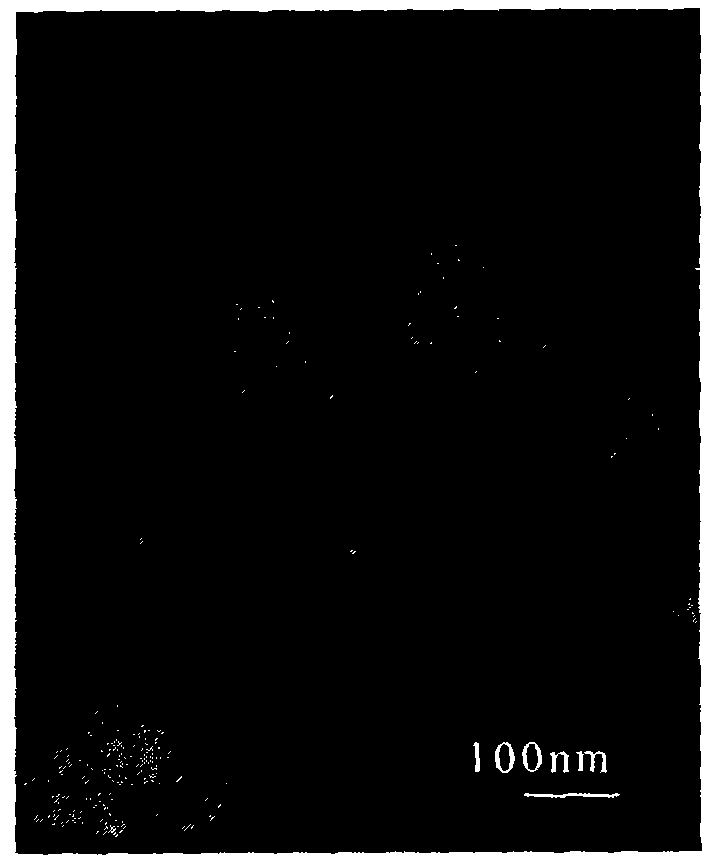

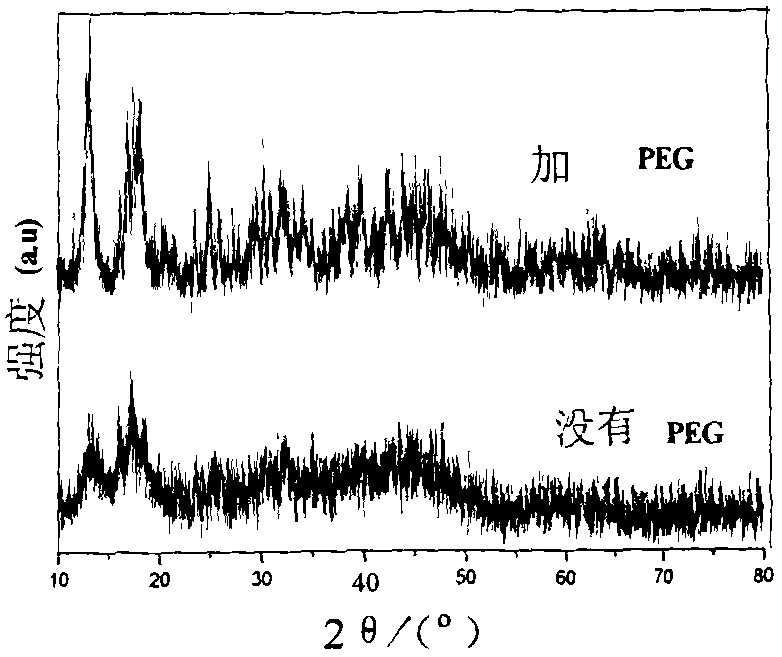

The invention relates to a chemical mechanical polishing abrasive particle CeO2 and a method for preparing the same, belonging to the rare earth powder material chemical preparation technical field. The invention is to prepare the CMP abrasive particle by utilization of cerous inorganic salt solution and homogeneous precipitation agent. The method comprises the following steps that: the cerous inorganic salt and the precipitation agent are prepared into solution with certain proportion; the solution is uniformly mixed through ultrasonic vibration; deposits are generated after the solution is heated to a certain temperature; serum is kept stand, aged, filtered and calcined, and then the CeO2 abrasive particle is prepared. The method also accelerates the nucleation rate through addition of surface active agent so as to reduce the reaction temperature, and simultaneously the nodulizing degree of the abrasive particle obtained is also good. The method prepares the CMP abrasive particle, wherein, the CMP abrasive particle belongs to the single-phase cubic crystal system; the space group is O<5>H-FM3M; the dispersibility is good; the grain fineness distribution is uniform; the shape is similar to a sphere; and the specific surface area BET is more than 0 and less than 50m<2> / g.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for chemically and mechanically polishing sapphire substrate slices in immersed mode

The invention relates to a method for chemically and mechanically polishing sapphire substrate slices in an immersed mode. The polishing method comprises the following steps that firstly, preprocessing is conducted, wherein the sapphire substrate slices are attached to a hard ceramic disk, the hard ceramic disk is installed on a main shaft of a polishing machine, a polishing gasket is installed on a rotating bottom disk, reverse osmosis pure water and a silicon dioxide polishing solution are mixed and added into the polishing machine, and the liquid level is kept between the upper liquid level line and the lower liquid level line of the polishing liquid; secondly, polishing is conducted, wherein the polishing machine is started for polishing the sapphire substrate slices, the polishing time ranges from 40 min to 80 min, and then the polished sapphire substrate slices are obtained; and thirdly, the finished sapphire substrate slices are washed. According to the chemical and mechanical polishing method, the temperature rising of the surface of the polishing gasket in the polishing process is small, the service life of the polishing gasket and an adsorption gasket is long, and no tiny scratch exists on the surfaces of the sapphire substrate slices in the polishing process.

Owner:TUNGHSU GRP

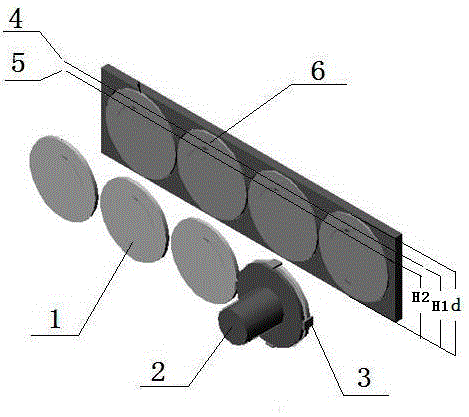

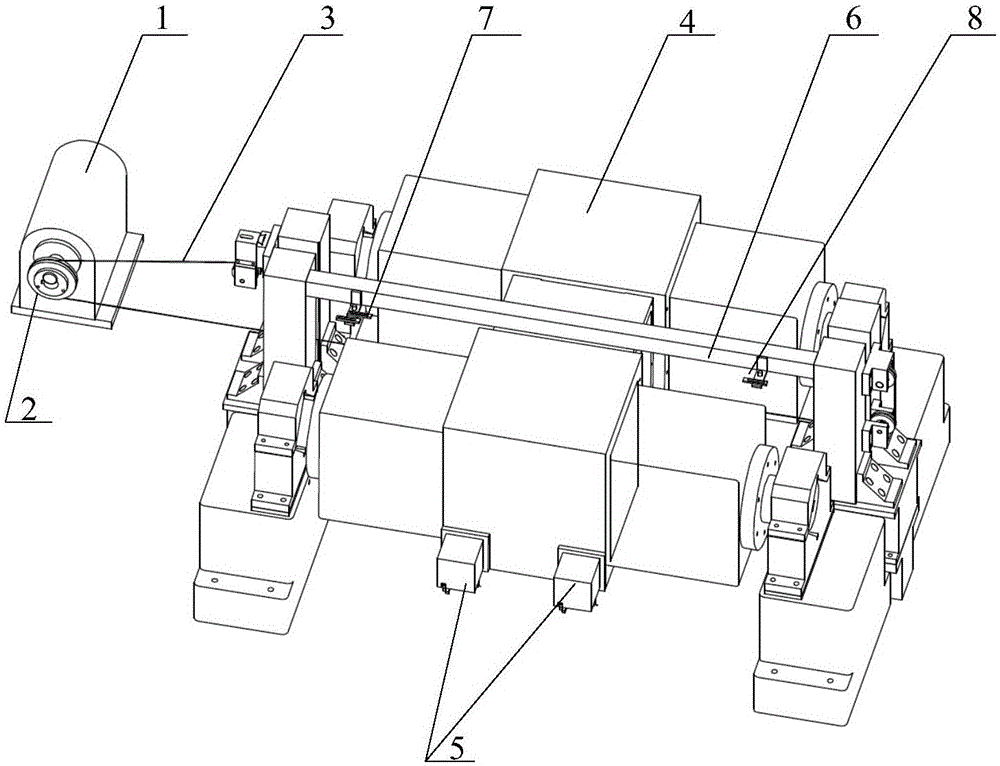

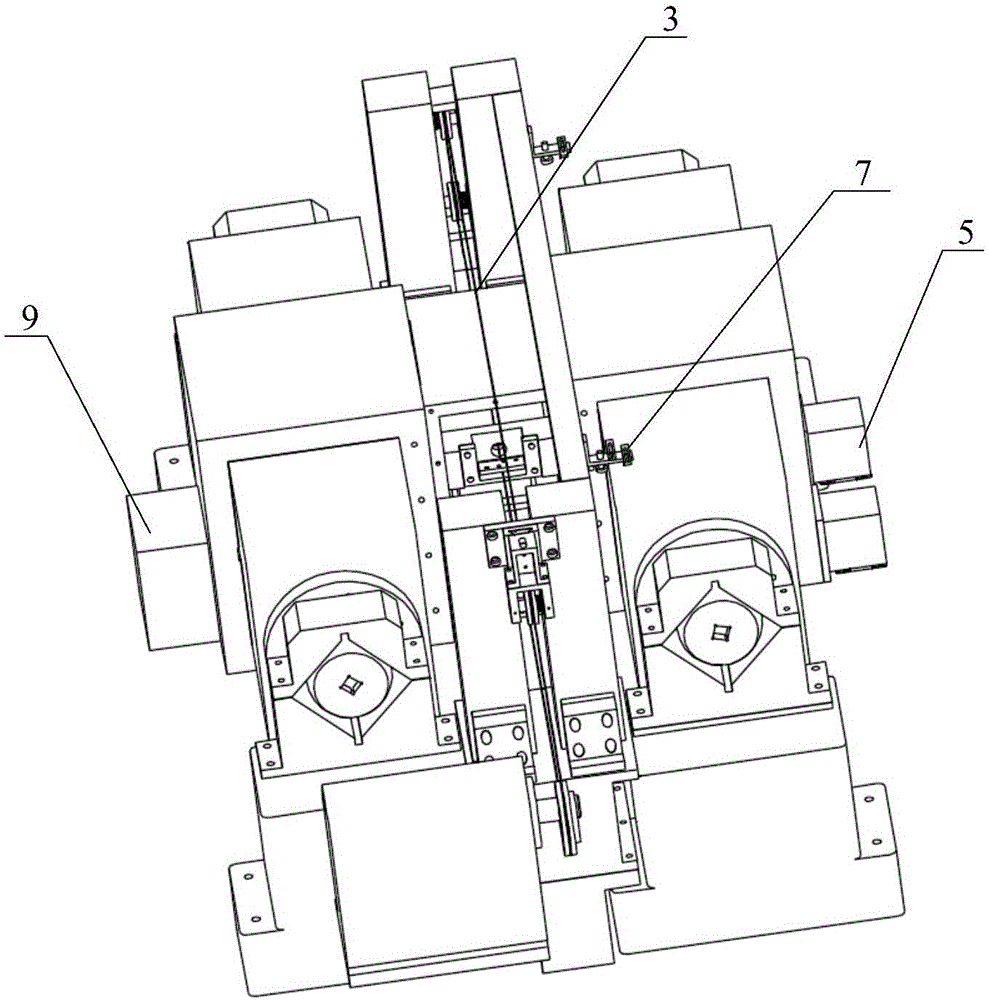

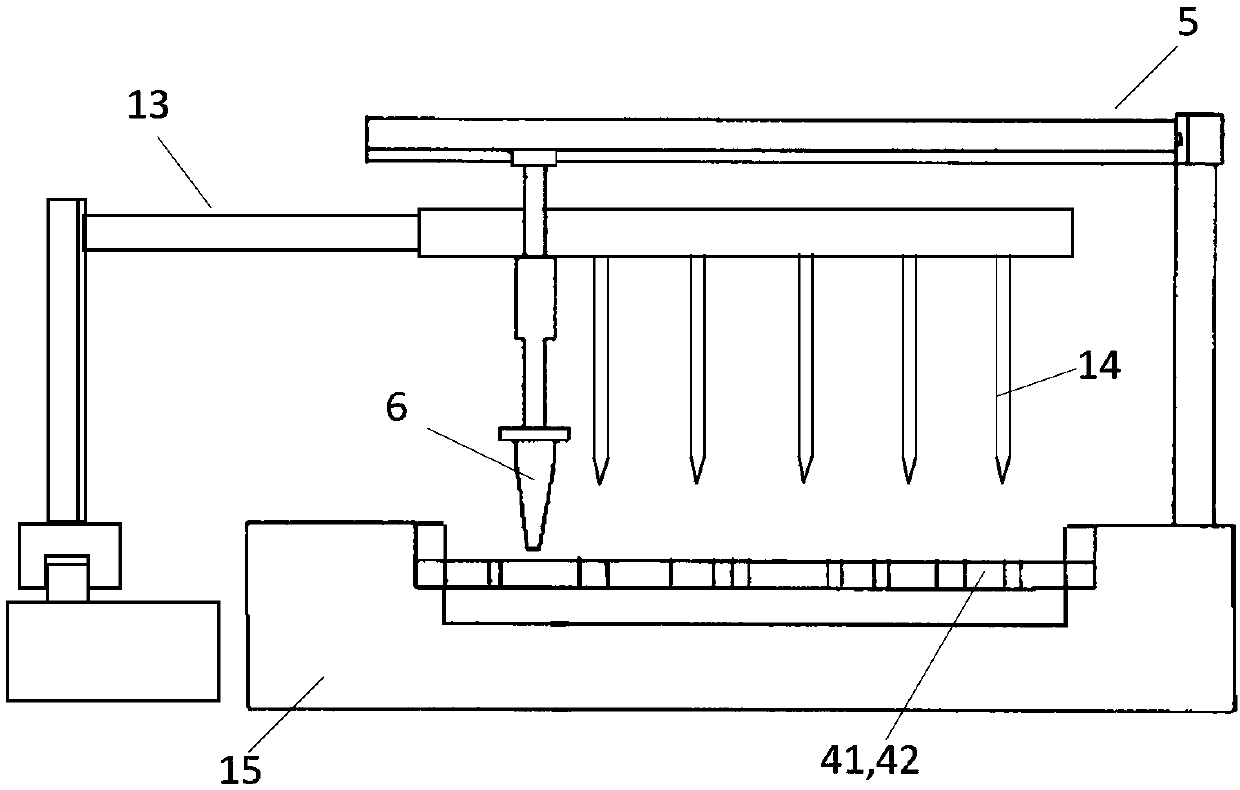

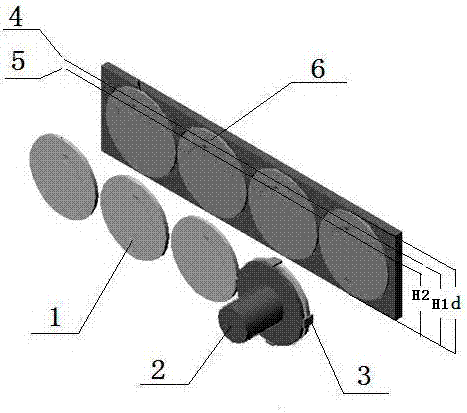

Optical grating ruling machine and ruling system therefor

InactiveCN106066502AReduce the number of scratchesShorten development timeDiffraction gratingsRule systemEngineering

The invention discloses a ruling system for an optical grating ruling machine. The ruling system comprise a support rack, a sliding sleeve, a guide rail and a driving system, wherein the sliding sleeve is provided with at least two groups of cutter frames that can slide on the guide rail in a reciprocating manner, and the driving system provides power support for reciprocating movement of the sliding sleeve. The ruling system disclosed in the application is provided with at least two groups of cutter frames for ruling at least two optical grating mother boards, ruling times can be reduced, optical grating manufacturing time can be shortened, and ruling efficiency can be improved. The invention also discloses the optical grating ruling machine equipped with the ruling system.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

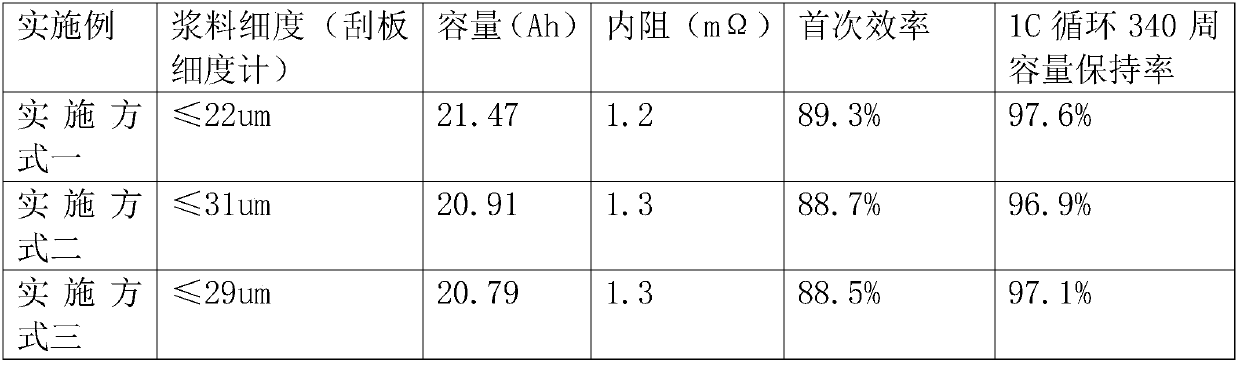

A lithium ion battery cathode slurry dispersing method

InactiveCN107744767AHigh solid contentImprove cycle performanceTransportation and packagingMixer accessoriesSlurrySolvent

The invention belongs to the technical field of lithium ion battery manufacturing, and particularly relates to a lithium ion battery cathode slurry dispersing method. The method includes 1) glue mixing, 2) powder stirring, 3) muddy stirring, 4) high-viscosity stirring, 5) viscosity adjusting and stirring, 6) viscosity adjusting and stirring, and 7) vacuum deaeration. Compared with conventional methods, the solid content of slurry prepared by the method can be greatly increased, dispersion effects are improved, the number of particle scratches is reduced, the solvent using amount is reduced, the cost is reduced, the first-time efficiency is increased, inner resistance is reduced, and cyclic performance of battery cores is improved.

Owner:CALB CO LTD

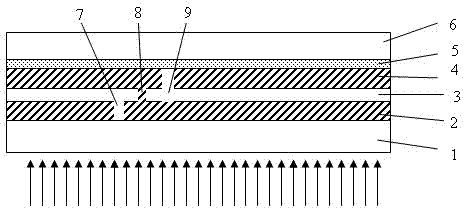

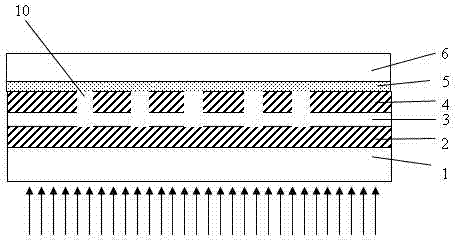

Method for manufacturing solar thin film light transmitting component

InactiveCN102376825ALarge scratch areaImprove maneuverabilityFinal product manufactureSemiconductor devicesElectricityElectrical battery

The invention relates to a method for manufacturing a solar thin film light transmitting component, belonging to the technical field of photovoltaic application. The manufacturing method adopts the following technical scheme: a front transparent electric conductive electrode, a thin film photoelectric conversion layer and a back electric conductive electrode are deposited on an insulating light transmitting substrate, and a plurality of son batteries are formed by cutting off the three thin films; then mechanical inscribing equipment is used for removing the front transparent electric conductive electrode, the thin film photoelectric conversion layer and the back electric conductive electrode (or the thin film photoelectric conversion layer and the back electric conductive electrode) in a direction parallel to or vertical to the son batteries, a pattern is inscribed by adjusting a needle head the equipment; as the photoelectric conversion layer in the patter is removed, therefore, lights can directly penetrate through the battery, thereby realizing the light transmitting function of the component. The manufacturing method can be used for realizing the preparation of the novel light transmitting component and has the characteristics of low cost, high efficiency, simple operation, short time consumption and the like while the output electrical property and the light transmission performance of the novel light transmitting component are not lower than that of the light transmitting component of the solar thin film battery prepared by the prior art.

Owner:BAODING TIANWEI GRP CO LTD

Metal surface grinding and polishing agent and preparation method thereof

InactiveCN108192506AIncrease flow rateConsistent surface temperaturePolishing compositions with abrasivesFoaming agentAnticoagulant

The invention relates to the technical field of metal surface treatment, in particular to a metal surface grinding and polishing agent and a preparation method thereof. The metal surface grinding andpolishing agent is prepared from the following ingredients in parts by weight: 16 to 33 parts of grinding agents, 1 to 2 parts of anti-foaming agents, 0.5 to 2 parts of sodium carbonate, 0.5 to 2 parts of surfactants, 0.5 to 2 parts of fatty alcohol ammonium sulfate, 0.5 to 1.5 parts of surface dimming agents, 0.5 to 1.5 parts of corrosion inhibitors, 0.2 to 0.5 part of suspending agents, 0.2 to 0.6 part of anticoagulants and 60 to 70 parts of water. By using the metal surface grinding and polishing agent provided by the invention, during the grinding and polishing on the metal surface, the multi-time coarse grinding and medium grinding links in the middle can be reduced; the production efficiency is improved.

Owner:东莞华拓研磨材料有限公司

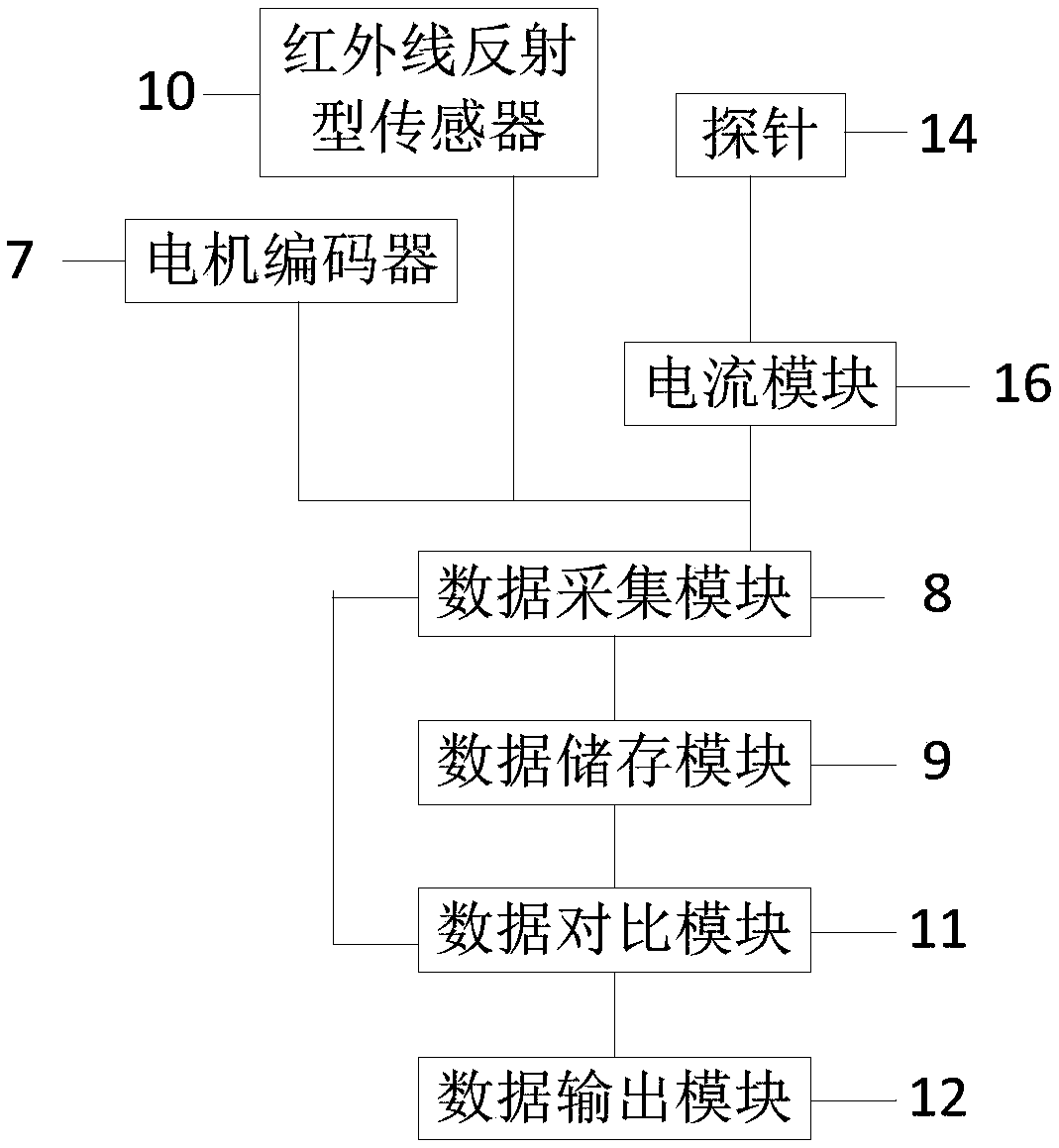

Fabrication method of printed circuit board

InactiveCN109561587AReduce appearance damageIncrease productivityInspection/indentification of circuitsPrinted circuit manufactureInfraredProduction rate

The invention provides a fabrication method of a printed circuit board. By designing a partition line during the formation step, the circuit board can be still connected with a plate after cutting andformation, particularly for fabrication of a small-size circuit board, a positioning hole is not needed to be formed in each circuit board, the appearance damage of the circuit board is reduced, andthe production efficiency and the qualified size of the circuit board are improved; in the detection step, the quality of a via hole, such as hole position and hole plug state can be judged by comparing difference between reflection intensity, detected by an infrared emission sensor, of an infrared ray after passing through a standard hole and a to-be-measured hole; and the quality of each loop ofthe circuit board is detected one by one, and the short-circuit condition of each loop of a to-be-detected circuit board is judged by comparing difference between inductance values, detected by a probe, of each loop of a standard circuit board and each loop of a to-be-detected circuit. The fabrication method has the advantages of high production rate, high detection efficiency, high detection accuracy and high cleaning efficiency and is convenient to process.

Owner:江门市利诺达电路科技有限公司

Preparation method of marble composite polishing powder

InactiveCN102925060BFine and uniform particlesSmall median diameterOther chemical processesPolishing compositions with abrasivesSlurryZirconium oxychloride

The invention discloses a preparation method of marble composite polishing powder and application of the preparation method in a polishing process of marble production and refurbishment. The method comprises dissolving 5%-18% of zirconium oxychloride in water, adding 50%-65% of aluminum oxide, adding 10%-22% of stannic oxide, adding 2%-8% of silicon dioxide, stirring to be slurry, adding 10%-25% of urea, conducting heating reaction, solid-liquid separation, drying and roasting, mixing with lead powder according to the proportion of 10-25:1, and then obtaining the marble composite polishing powder. The preparation process is simple, preparation methods are easy to control, production cost is low, and industrial production is easy to achieve. The preparation method is used for a marble polishing procedure, the marble composite polishing powder has good polishing effects, glossiness can achieve more than 98 degrees, scratches are fewer, evenness is high, and using amount of the powder is less.

Owner:UNIV OF JINAN

Preparation method of marble polishing powder

InactiveCN107446506AComplementary soft and hard, good fluidityGood mechanical grinding abilityOther chemical processesPolishing compositions with abrasivesOxalateChemical reaction

The invention discloses a preparation method of marble polishing powder. The method is characterized by comprising the following process steps of adding the following ingredients in percentage concentration by mass into a grinding machine: 47 to 53 percent of oxalate dihydrate, 12 to 15 percent of aluminum oxide and 5 to 10 percent of stannic oxide; performing grinding and uniform mixing; adding 6 to 10 percent of sodium binoxalate and 15 to 21 percent of stearic acid; performing grinding and uniform mixing; then adding 2 to 4 percent of paraffin powder and 0.3 to 1.0 percent of fatty alcohol polyoxy ether, wherein the sum of all ingredients is hundred percent; performing grinding and uniform mixing; obtaining the marble polishing powder with the particle diameter being 2.0 to 10 mu m. The polishing powder has the advantages that chemical reaction is taken between the polishing powder and marble in the polishing process; the chemical polishing characteristics are realized, so that the polishing effect of the polishing powder is good; the luster degree is high; scratch marks are few; the flatness and smoothness degree is high; the consumption is low; the corrosion of oxalic acid can be buffered through the addition of the sodium binoxalate.

Owner:UNIV OF JINAN

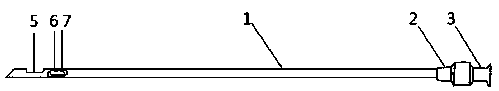

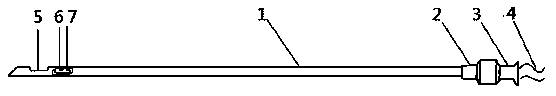

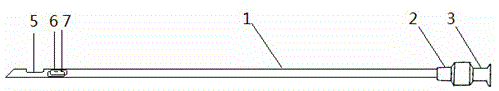

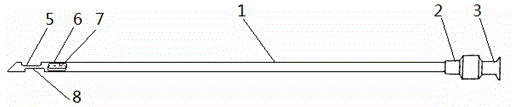

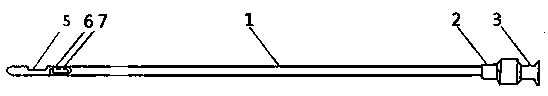

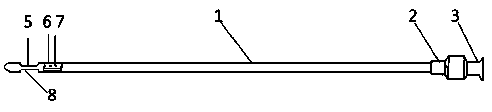

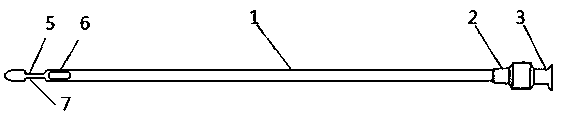

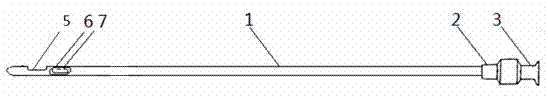

Axillary osmidrosis suction and scraping needle with pointed end

ActiveCN103417259AShorten the lengthReduce distanceSurgerySuction devicesReoperative surgeryBiomedical engineering

The invention provides an axillary osmidrosis suction and scraping needle with a pointed end. The axillary osmidrosis suction and scraping needle with the pointed end is composed of a sucker body, a connector and a handle, wherein the front end of the sucker body is the pointed end, a positive side hole is formed in a sharp inclined face in an open state and is located in the same direction with the inclined face, a left side hole and a right side hole are formed in the two sides of the positive side hole, and a three-hole suction and scraping needle is formed; or a negative side hole is formed in the back face of the positive side hole, and a four-hole suction and scraping needle is formed. According to the axillary osmidrosis suction and scraping needle with the pointed end, the number, the size and the arrangement design of the side holes are reasonable, a whole holding portion can be covered, sucked and scraped by the needle at a time, the suction and scraping holes are reasonable in arrangement, and the portion within the small range can also be sucked and scraped. The pointed end inclined face facilitates inserting of the needle tightly attached to the dermis deep face, meanwhile, the inclined face of the pointed end is an effective suction and scraping part, requirements of a surgery are met, using is safe and effective, and population and using are easy.

Owner:ZHEJIANG UNIV

Method for preparing blue marble polishing powder

InactiveCN107474745AImprove liquidityGood mechanical grinding abilityOther chemical processesPolishing compositions with abrasivesOxalateRoom temperature

The invention discloses a method for preparing blue marble polishing powder. The method is characterized by comprising the following steps: (1) preparing an AlN-ZrO2 complex, namely adding the following components: 40-60% of water, 20-26% of zirconium oxychloride, 30-36% of nano aluminum nitride and 1-5% of sodium hydroxide, stirring and reacting at a room temperature for 30 minutes, performing solid-liquid separation, drying at the temperature of 105+ / -2 DEG C, roasting at the temperature of 550+ / -10 DEG C for 2 hours, cooling, and performing air jet milling so as to prepare the AlN-ZrO2 complex; and (2) adding the following components into a grinder: 40-45% of oxalate dehydrate, 18-22% of the AlN-ZrO2 complex and 4-8% of cupric oxalate, grinding, uniformly mixing, adding 8-12% of ammonium binoxalate and 18-24% of stearic acid, grinding, uniformly mixing, adding 0.3-1.0%of a nonionic surfactant, uniformly mixing, thereby obtaining the blue marble polishing powder. The polishing powder has the chemical polishing characteristic. Therefore, the polishing powder is excellent in polishing effect, high in glossiness, less in scratch, high in flatness and small in usage amount.

Owner:UNIV OF JINAN

Preparation method of polishing powder for polishing water grindstone

InactiveCN107446508ASmall median diameterNarrow particle size distributionPolishing compositions with abrasivesROSIN POWDEROxalate

The invention discloses a preparation method of polishing powder for polishing a water grindstone. The preparation method is characterized in that a Cr2O3-Fe2O3-SnO2 compound is used as a grinding material, oxalic acid is used as an acidic polishing agent, and additives including a dispersant, a surfactant and the like are added to prepare the polishing powder. The specific preparation method comprises the following steps: in a grinding machine, adding the following components according to the following mass percent concentration: 10 percent to 15 percent of the Cr2O3-Fe2O3-SnO2 compound, 50 percent to 55 percent of oxalic acid dihydrate and 15 percent to 20 percent of ammonium bioxalate; grinding the materials and uniformly mixing; adding 4 percent to 8 percent of rosin powder and 6 percent to 12 percent of stearic acid, and grinding and uniformly mixing; adding 1.0 percent to 3.0 percent of a non-ionic surfactant, wherein the sum of all the components is 100 percent; grinding and uniformly mixing to prepare the water grindstone polishing powder. The polishing powder disclosed by the invention has a good polishing effect, high glossiness, fewer scratches, high flatness and a small dosage; the ammonium bioxalate is added so that the corrosion performance of the oxalic acid can be buffered.

Owner:UNIV OF JINAN

Abrasive grain CeO2 for chemical and mechanical buffing and method for preparing same

ActiveCN101284952BReduce surface roughnessImprove flatnessPigmenting treatmentSemiconductor/solid-state device manufacturingSpace groupCerium

The invention relates to a chemical mechanical polishing abrasive particle CeO2 and a method for preparing the same, belonging to the rare earth powder material chemical preparation technical field. The invention is to prepare the CMP abrasive particle by utilization of cerous inorganic salt solution and homogeneous precipitation agent. The method comprises the following steps that: the cerous inorganic salt and the precipitation agent are prepared into solution with certain proportion; the solution is uniformly mixed through ultrasonic vibration; deposits are generated after the solution is heated to a certain temperature; serum is kept stand, aged, filtered and calcined, and then the CeO2 abrasive particle is prepared. The method also accelerates the nucleation rate through addition of surface active agent so as to reduce the reaction temperature, and simultaneously the nodulizing degree of the abrasive particle obtained is also good. The method prepares the CMP abrasive particle, wherein, the CMP abrasive particle belongs to the single-phase cubic crystal system; the space group is O<5>H-FM3M; the dispersibility is good; the grain fineness distribution is uniform; the shape is similar to a sphere; and the specific surface area BET is more than 0 and less than 50m<2> / g.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Pointed underarm odor shaving needle

ActiveCN103417259BAvoid damageDegree of reductionSurgerySuction devicesReoperative surgeryBiomedical engineering

The invention provides an axillary osmidrosis suction and scraping needle with a pointed end. The axillary osmidrosis suction and scraping needle with the pointed end is composed of a sucker body, a connector and a handle, wherein the front end of the sucker body is the pointed end, a positive side hole is formed in a sharp inclined face in an open state and is located in the same direction with the inclined face, a left side hole and a right side hole are formed in the two sides of the positive side hole, and a three-hole suction and scraping needle is formed; or a negative side hole is formed in the back face of the positive side hole, and a four-hole suction and scraping needle is formed. According to the axillary osmidrosis suction and scraping needle with the pointed end, the number, the size and the arrangement design of the side holes are reasonable, a whole holding portion can be covered, sucked and scraped by the needle at a time, the suction and scraping holes are reasonable in arrangement, and the portion within the small range can also be sucked and scraped. The pointed end inclined face facilitates inserting of the needle tightly attached to the dermis deep face, meanwhile, the inclined face of the pointed end is an effective suction and scraping part, requirements of a surgery are met, using is safe and effective, and population and using are easy.

Owner:ZHEJIANG UNIV

Preparation method of boron nitride composite polishing solution

InactiveCN105860855ASmall median diameterNarrow particle size distributionPolishing compositions with abrasivesAmmonium dichromateLignosulfonates

The invention discloses a preparation method of a boron nitride composite polishing solution. The preparation method is characterized in that by mass, 28-38% of water, 18-26% of ammonium dichromate, 12-20% of zirconium oxychloride and 24-32% of nano boron nitride are added to a grinding machine, the grinding machine is started, and a BN-Cr2O3-ZrO2 compound is prepared through grinding, drying and calcining; by mass, 70-78% of water, 2.0-4.0% of lignosulfonate, 3.0-5.0% of isopropyl alcohol, 1.0-5.0% of potassium bromate and 14-22% of BN-Cr2O3-ZrO2 compound are added to a reactor, a stirring reaction is conducted for 4-6 h at the rotating speed of 300 r / min, and the boron nitride composite polishing solution is obtained. The preparation process is simple, conditions are easy to control, the production cost is low, and industrial production is easy. In the polishing process, the advantages of being good in liquid polishing effect, free of scratches, high in flatness, small in dosage, resistant to abrasion and easy to wash are achieved.

Owner:UNIV OF JINAN

A kind of preparation method of blue marble polishing powder

InactiveCN107474745BImprove liquidityGood mechanical grinding abilityOther chemical processesPolishing compositions with abrasivesOxalateActive agent

The invention discloses a method for preparing blue marble polishing powder. The method is characterized by comprising the following steps: (1) preparing an AlN-ZrO2 complex, namely adding the following components: 40-60% of water, 20-26% of zirconium oxychloride, 30-36% of nano aluminum nitride and 1-5% of sodium hydroxide, stirring and reacting at a room temperature for 30 minutes, performing solid-liquid separation, drying at the temperature of 105+ / -2 DEG C, roasting at the temperature of 550+ / -10 DEG C for 2 hours, cooling, and performing air jet milling so as to prepare the AlN-ZrO2 complex; and (2) adding the following components into a grinder: 40-45% of oxalate dehydrate, 18-22% of the AlN-ZrO2 complex and 4-8% of cupric oxalate, grinding, uniformly mixing, adding 8-12% of ammonium binoxalate and 18-24% of stearic acid, grinding, uniformly mixing, adding 0.3-1.0%of a nonionic surfactant, uniformly mixing, thereby obtaining the blue marble polishing powder. The polishing powder has the chemical polishing characteristic. Therefore, the polishing powder is excellent in polishing effect, high in glossiness, less in scratch, high in flatness and small in usage amount.

Owner:UNIV OF JINAN

A kind of preparation method of granite polishing powder

InactiveCN107446507BEasy to polishSmall median diameterOther chemical processesPolishing compositions with abrasivesCerous chloridePhysical chemistry

The invention discloses a preparation method of granite polishing powder. The preparation method is characterized by comprising the steps of (1) preparation of ZrN-CeO2-SiO2 compounds: the following ingredients including 38 to 44 percent of water, 25 to 30 percent of cerium chloride, 15 to 20 percent of zirconium nitride and 8 to 12 percent of silicon dioxide are added; after stirring and dissolution, 4 to 8 percent of ammonium hydroxide is added; room-temperature stirring and reaction are performed for 40 min; solid-liquid separation is performed; drying and roasting are performed for 2h; cooling and smashing are performed to prepare the faint yellow ZrN-CeO2-SiO2 compound; (2) preparation of granite polishing powder: the following ingredients including 22 to 28 percent of ZrN-CeO2-SiO2 compounds, 10 to 15 percent of oxalate dihydrate and 15 to 20 percent of sodium oxalate are added, are ground and are uniformly mixed; 20 to 25 percent of ammonium fluozirconate and 20 to 25 percent of palmitic acid are added, and are ground and uniformly mixed; 2.0 to 4.0 percent of paraffin powder is added; grinding and uniform mixing are performed to obtain the faint yellow granite polishing powder. The characteristic of chemical polishing is realized, so that the polishing effect of the chemical polishing powder is good; the glossiness can reach 98 degrees or higher; the scratch number is small; the flatness is high; the consumption is low.

Owner:UNIV OF JINAN

A sapphire substrate submerged chemical mechanical polishing method

Owner:TUNGHSU GRP

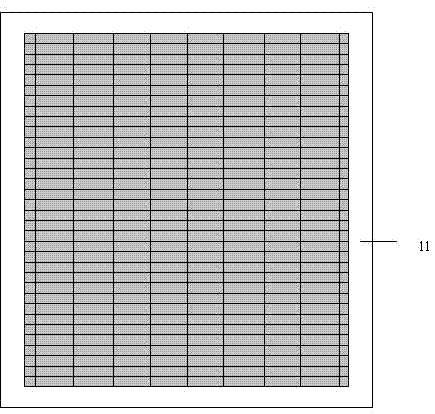

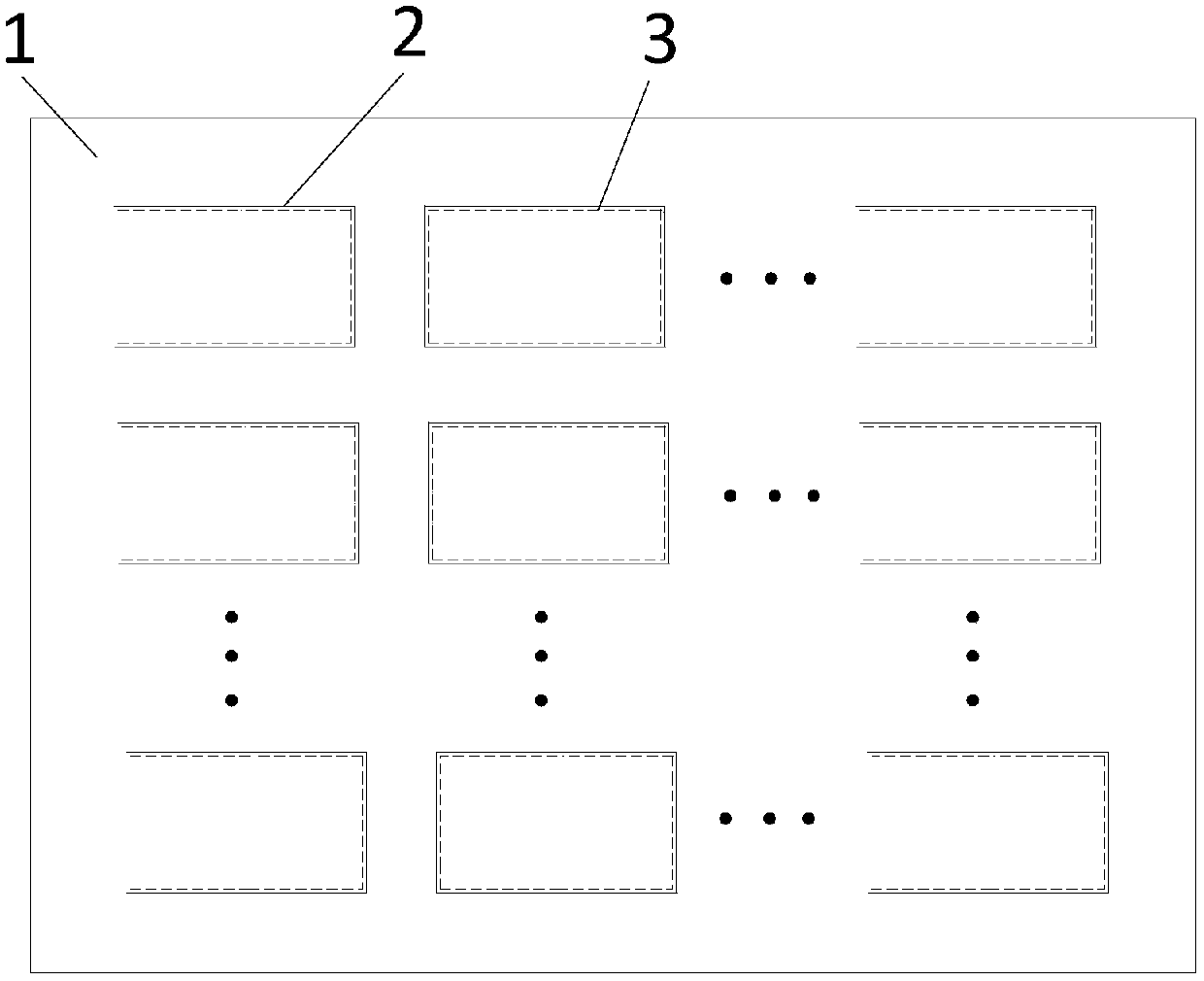

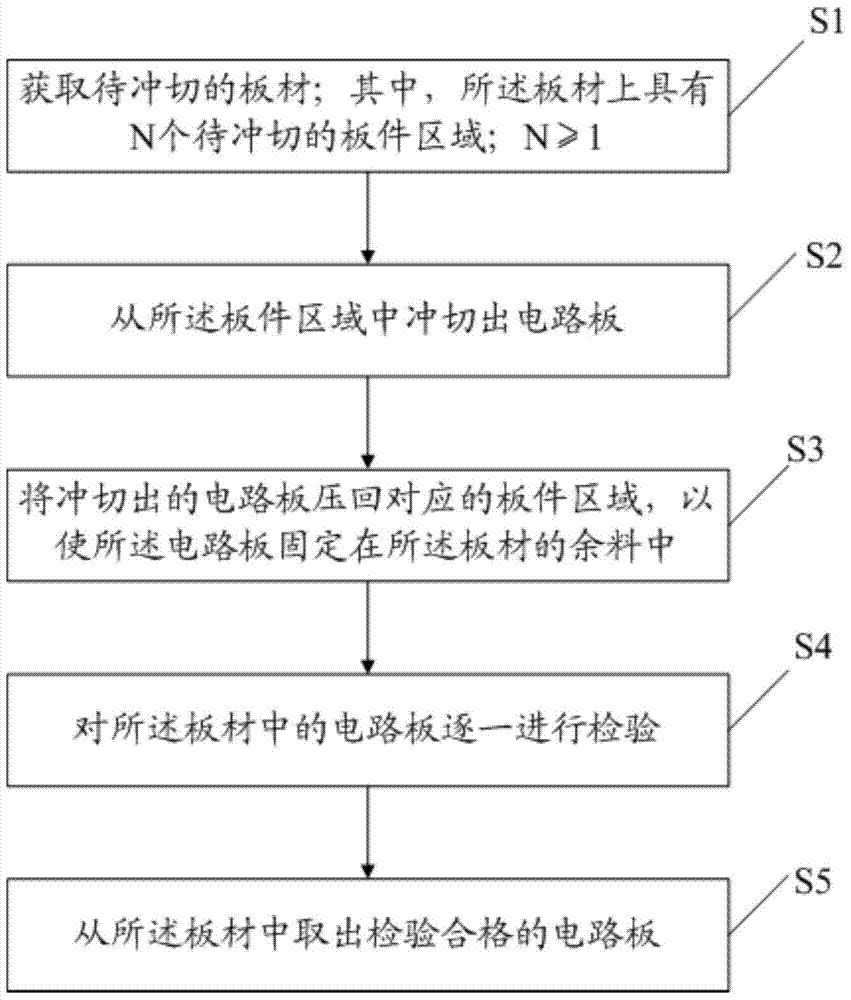

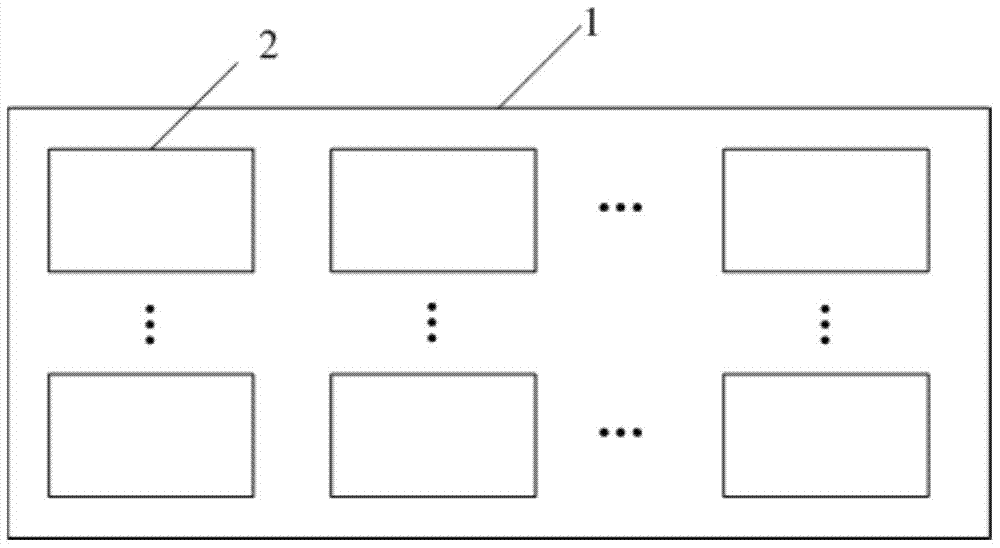

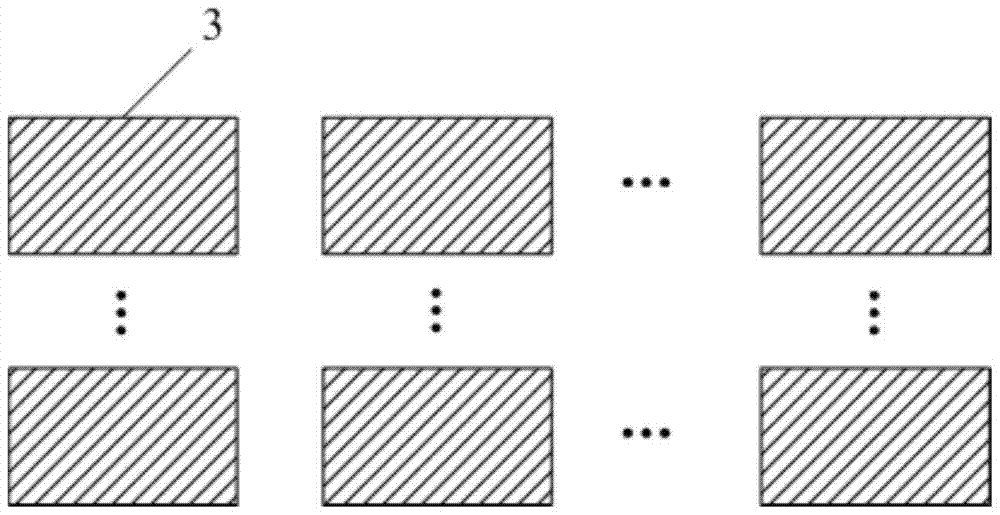

A method of manufacturing a circuit board

ActiveCN104768329BReduce appearance damageIncrease productivityPrinted circuit manufactureEngineeringElectrical and Electronics engineering

The invention discloses a method for manufacturing a circuit board, comprising: obtaining a plate to be punched; wherein, the plate has N plate areas to be punched; N≥1; punching from the plate area Cutting out the circuit board; pressing the punched out circuit board back to the corresponding panel area so that the circuit board is fixed in the remaining material of the panel; inspecting the circuit boards in the panel one by one; Take out the qualified circuit board from the board. By adopting the embodiment of the present invention, the production efficiency and inspection accuracy of the circuit board can be improved.

Owner:GCI SCI & TECH

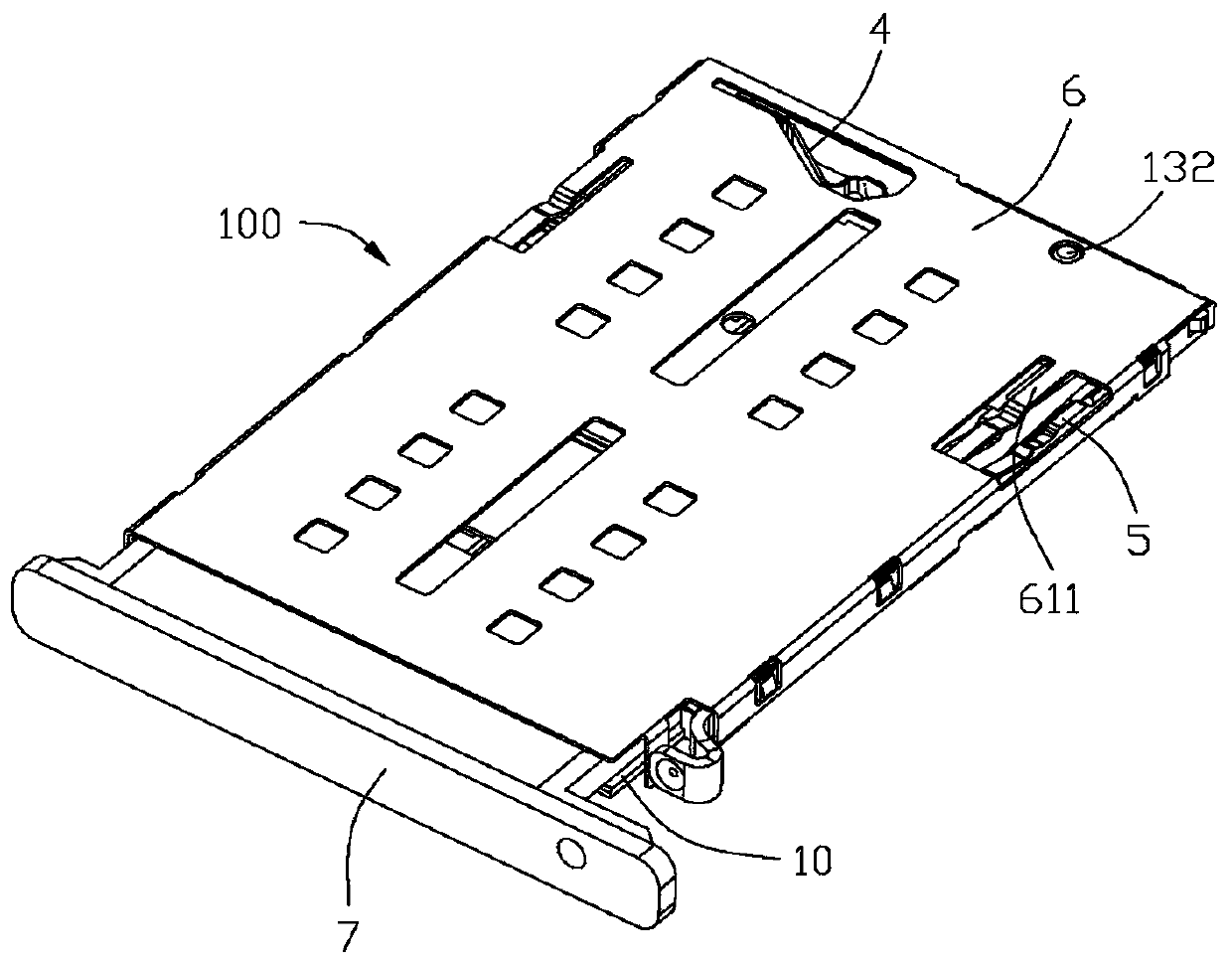

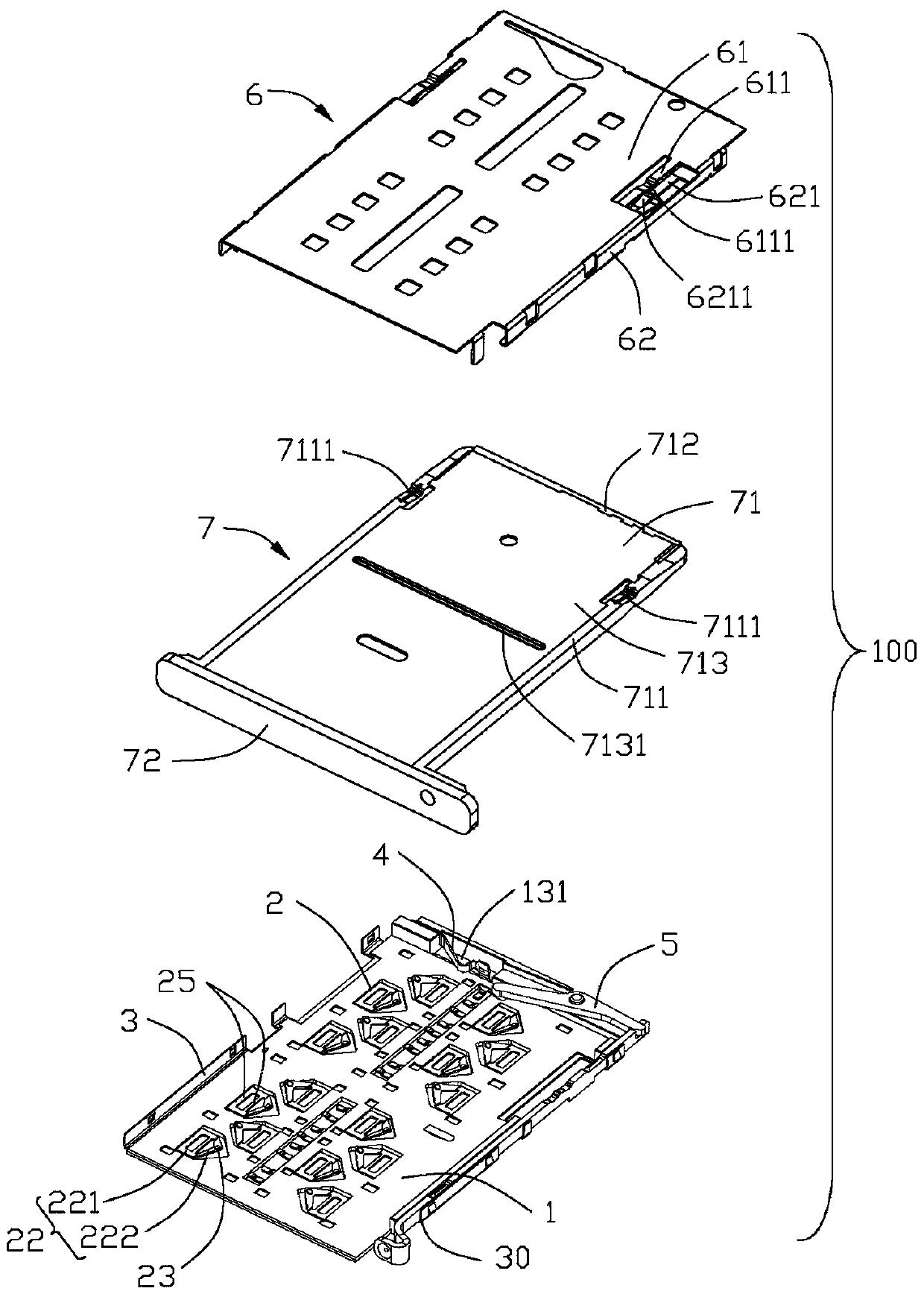

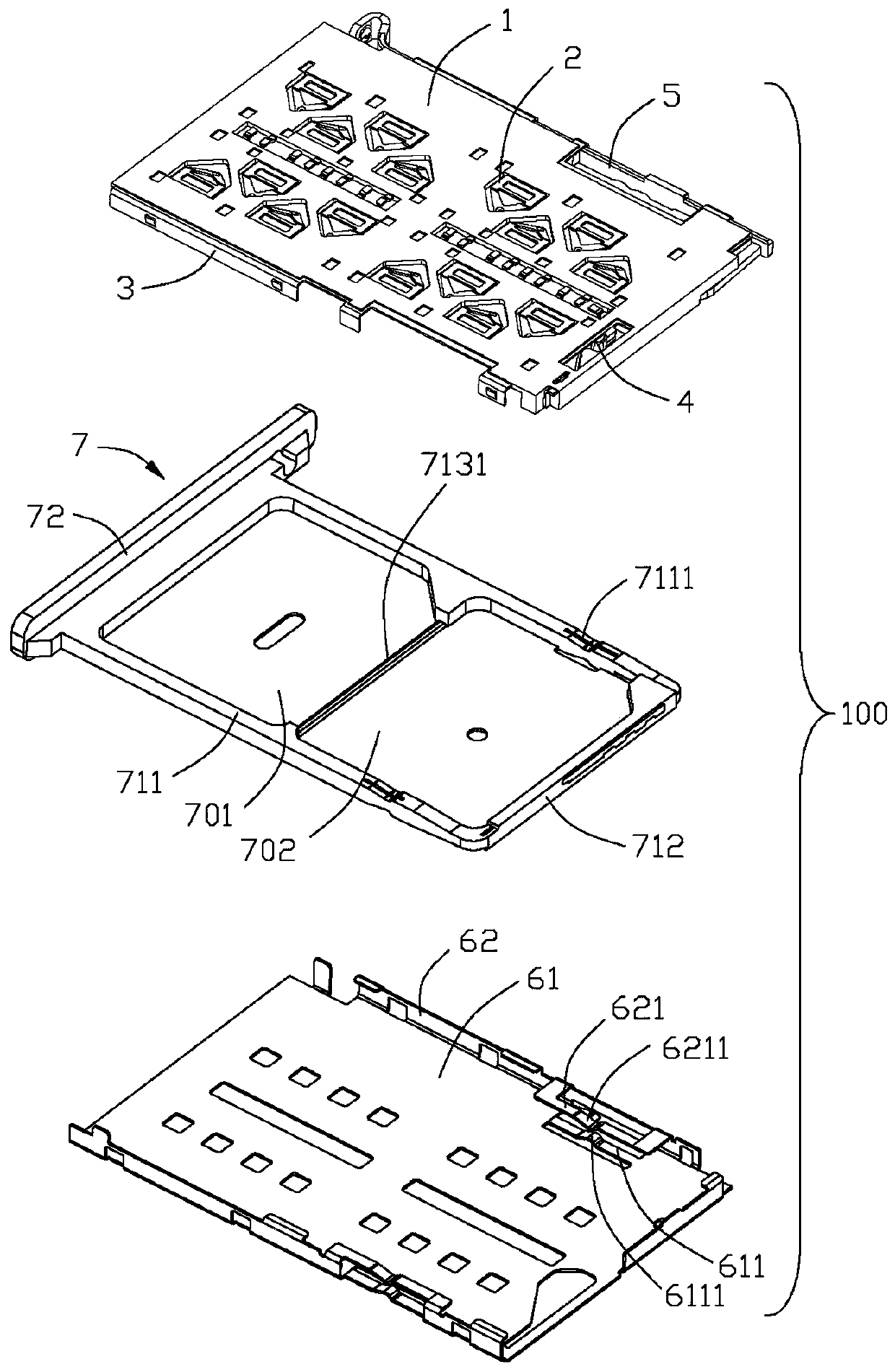

card connector

ActiveCN106207566BNot easy to break downAvoid deformationConveying record carriersSecuring/insulating coupling contact membersSharp angleEngineering

An electronic card connector (100) includes an insulative housing (1), a number of terminals (2), and a shielding shell (6). Each terminal includes an elastic portion extending upwardly and a contacting portion (23). The elastic portion is resiliently deformable in an up-to-down direction. A first part of the elastic portion is located in a first plane, and a second part of the elastic portion is located in a second plane forming a sharp angle with the first plane. The second part has a connecting portion (25) and a pair of frame portions (26) connected with two free ends of the connecting portion. Each terminal defines a front point and a rear point respectively located on the elastic portion. The front point is located at the front of the contacting portion and the rear point is located at the rear of the contacting portion along a card-inserting direction.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD

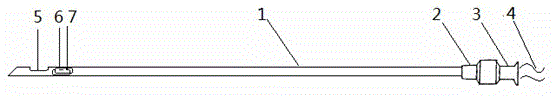

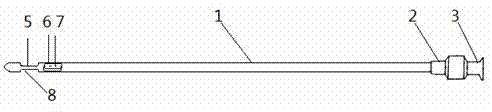

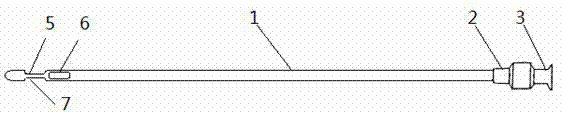

Axillary osmidrosis pumping and scraping needle with round head

The invention provides an axillary osmidrosis pumping and scraping needle with a round head. The axillary osmidrosis pumping and scraping needle with the round head is composed of a sucking pipe body, a connector and a handle. The sucking pipe body is a cylindrical hollow pipe, the connector is located at the tail end of the sucking pipe body, the sucking pipe body is connected with the handle through the connector, the front end of the sucking pipe body is in the shape of a closed cone, a relatively-pointed head end is arranged at the front end of the sucking pipe body, and three or four side holes are formed in the portion close to the head end. According to the axillary osmidrosis pumping and scraping needle with the round head, the number, size, arrangement and the like of the side holes are reasonable in design, the side holes can pump, scrape and cover the whole holding position at a time, the pumping and scraping holes are reasonable in arrangement, and a small range can also be pumped and scraped. The design of the conical front end enables the needle to be tightly attached to and inserted into the deep face of the corium along the original layer face, the situations that the skin is penetrated, an operator is injured, and muscles in the deep face are damaged are avoided, and the axillary osmidrosis pumping and scraping needle with the round head meets operation requirements, is safe and effective to use, and easy to popularize and use.

Owner:ZHEJIANG UNIV

A kind of preparation method of marble polishing powder

InactiveCN107446506BComplementary soft and hard, good fluidityGood mechanical grinding abilityOther chemical processesPolishing compositions with abrasivesOXALIC ACID DIHYDRATEStearic acid

The invention discloses a preparation method of marble polishing powder. The method is characterized by comprising the following process steps of adding the following ingredients in percentage concentration by mass into a grinding machine: 47 to 53 percent of oxalate dihydrate, 12 to 15 percent of aluminum oxide and 5 to 10 percent of stannic oxide; performing grinding and uniform mixing; adding 6 to 10 percent of sodium binoxalate and 15 to 21 percent of stearic acid; performing grinding and uniform mixing; then adding 2 to 4 percent of paraffin powder and 0.3 to 1.0 percent of fatty alcohol polyoxy ether, wherein the sum of all ingredients is hundred percent; performing grinding and uniform mixing; obtaining the marble polishing powder with the particle diameter being 2.0 to 10 mu m. The polishing powder has the advantages that chemical reaction is taken between the polishing powder and marble in the polishing process; the chemical polishing characteristics are realized, so that the polishing effect of the polishing powder is good; the luster degree is high; scratch marks are few; the flatness and smoothness degree is high; the consumption is low; the corrosion of oxalic acid can be buffered through the addition of the sodium binoxalate.

Owner:UNIV OF JINAN

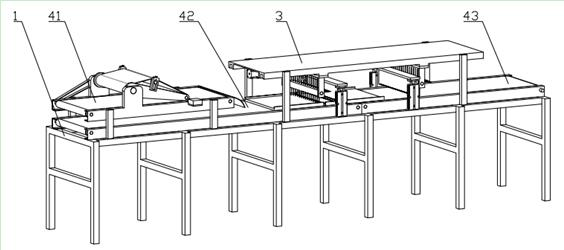

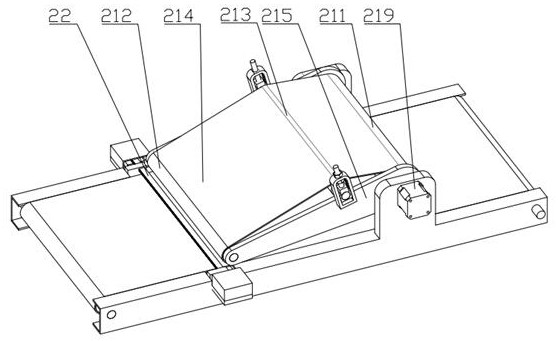

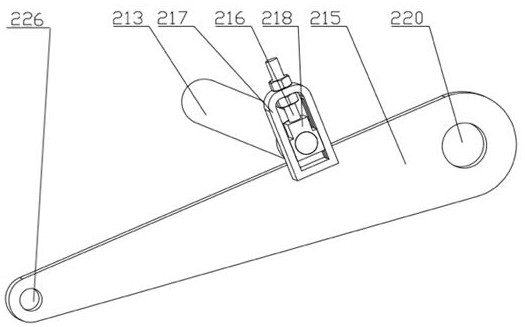

Slicing and shredding integrated equipment for undaria pinnatifida stems

InactiveCN114603634ALow costIncrease productivityMetal working apparatusStructural engineeringUndaria pinnatifida

Owner:DALIAN POLYTECHNIC UNIVERSITY

Underarm odor shaving needle with round head

The invention provides an axillary osmidrosis pumping and scraping needle with a round head. The axillary osmidrosis pumping and scraping needle with the round head is composed of a sucking pipe body, a connector and a handle. The sucking pipe body is a cylindrical hollow pipe, the connector is located at the tail end of the sucking pipe body, the sucking pipe body is connected with the handle through the connector, the front end of the sucking pipe body is in the shape of a closed cone, a relatively-pointed head end is arranged at the front end of the sucking pipe body, and three or four side holes are formed in the portion close to the head end. According to the axillary osmidrosis pumping and scraping needle with the round head, the number, size, arrangement and the like of the side holes are reasonable in design, the side holes can pump, scrape and cover the whole holding position at a time, the pumping and scraping holes are reasonable in arrangement, and a small range can also be pumped and scraped. The design of the conical front end enables the needle to be tightly attached to and inserted into the deep face of the corium along the original layer face, the situations that the skin is penetrated, an operator is injured, and muscles in the deep face are damaged are avoided, and the axillary osmidrosis pumping and scraping needle with the round head meets operation requirements, is safe and effective to use, and easy to popularize and use.

Owner:ZHEJIANG UNIV

A kind of preparation method of terrazzo polishing powder

InactiveCN107502201BSmall median diameterNarrow particle size distributionOther chemical processesPolishing compositions with abrasivesOXALIC ACID DIHYDRATEActive agent

Owner:UNIV OF JINAN

A kind of preparation method of boron nitride composite polishing liquid

InactiveCN105860855BSmall median diameterNarrow particle size distributionPolishing compositions with abrasivesLignosulfonatesBoron nitride

The invention discloses a method for preparing a boron nitride composite polishing liquid, which is characterized in that, in the grinder, the following composition mass percentage concentration is added, water: 28-38%, ammonium dichromate: 18-26%, Zirconium oxychloride: 12~20%, nano-boron nitride: 24~32%, turn on the grinder, grind, dry, and roast to obtain the BN‑Cr2O3‑ZrO2 compound; then in the reactor, the composition mass is as follows Concentration added, water: 70~78%, lignosulfonate: 2.0~4.0%, isopropanol: 3.0~5.0%, potassium bromate: 1.0~5.0%, BN‑Cr2O3‑ZrO2 complex: 14~22 %, at a speed of 300 r / min, stir and react for 4~6h to obtain a boron nitride composite polishing solution. The preparation process is simple, the conditions are easy to control, the production cost is low, and the industrial production is easy. During the polishing process, it has a good liquid polishing effect, no scratches, high flatness, less dosage, anti-corrosion, and easy to wash.

Owner:UNIV OF JINAN

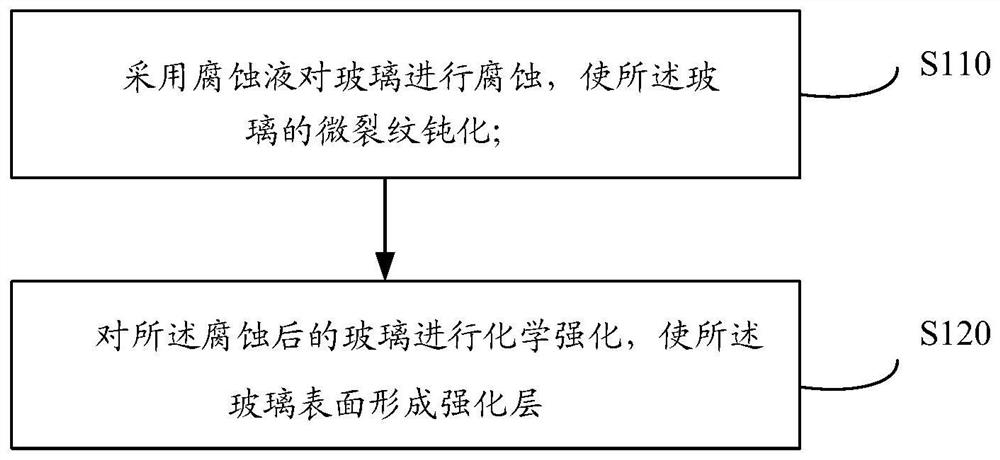

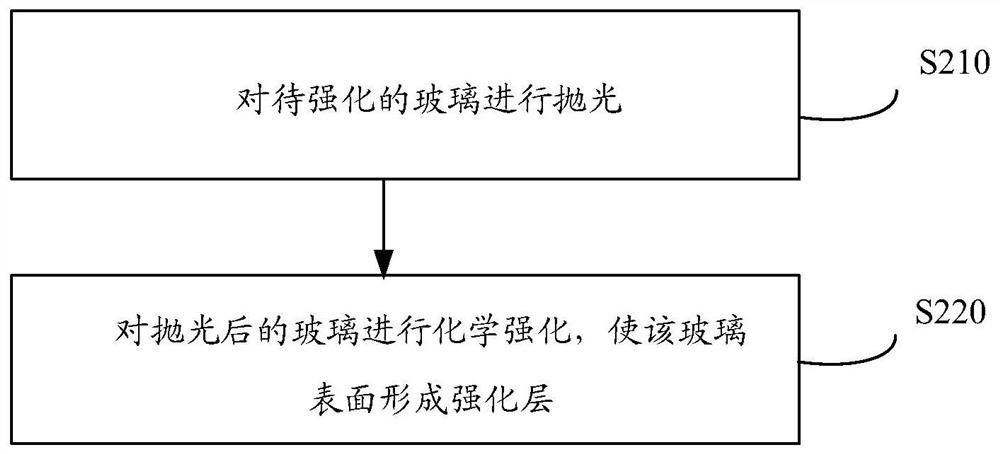

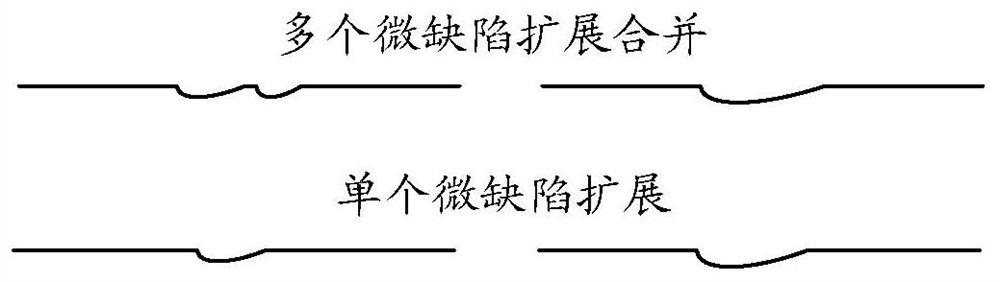

Glass strengthening method

The invention provides a glass strengthening method, and relates to the technical field of glass processing. The glass strengthening method comprises the following steps: corroding glass by adopting corrosive liquid to passivate micro-cracks of the glass; and carrying out chemical strengthening on the corroded glass to form a strengthening layer on the surface of the glass. According to the glassstrengthening method, corrosion strengthening is carried out before chemical strengthening, so that the strength of the glass can be effectively enhanced, and weakening of corrosion strengthening andeven counteracting of the strengthening effect of chemical strengthening are avoided.

Owner:HUAWEI TECH CO LTD

A kind of preparation method of polishing powder for granite polishing

InactiveCN107603488BEasy to polishSmall median diameterOther chemical processesOXALIC ACID DIHYDRATEBoronic acid

The invention discloses a preparation method of polishing powder for granite polishing. The preparation method is characterized by comprising the following steps: (1) preparation of a ZrN-ZrO2-SiN2 compound: adding the following components: 42-48% of water, 25-30% of zirconium oxychloride, 10-15% of zirconium nitride and 10-15% of silicon nitride, performing stirring for dissolution, adding 2-4% of sodium hydroxide, performing stirring reaction at a room temperature, performing solid-liquid separation, drying, roasting, and crushing to obtain the ZrN-ZrO2-SiN compound; and (2) preparation thepolishing powder for granite: adding 32-38% of the ZrN-ZrO2-SiN compound, 12-18% of oxalic acid and 12-18% of ammonium binoxalate, performing grinding and uniform mixing, adding 15-20% of ammonium fluoborate and 15-20% of stearic acid, performing grinding and uniform mixing, adding 1.0-2.0% of sodium dodecyl sulfate, and performing grinding and uniform mixing to obtain the polishing powder for granite. The polishing powder has the characteristics of chemical polishing, and has a good polishing effect, high glossiness, few scratches, and high flatness and a small usage amount, and the corrosionof oxalic acid can be buffered with the addition of the ammonium bioxalate.

Owner:UNIV OF JINAN

A kind of preparation method for marble polishing liquid

InactiveCN105925199BFine median diameterSmall median diameterPolishing compositions with abrasivesSal ammoniacPolyethylene glycol

Owner:UNIV OF JINAN

Preparation method of polishing powder for granite polishing

InactiveCN107603488AEasy to polishSmall median diameterOther chemical processesPolishing compositions with abrasivesDissolutionZirconium oxychloride

The invention discloses a preparation method of polishing powder for granite polishing. The preparation method is characterized by comprising the following steps: (1) preparation of a ZrN-ZrO2-SiN2 compound: adding the following components: 42-48% of water, 25-30% of zirconium oxychloride, 10-15% of zirconium nitride and 10-15% of silicon nitride, performing stirring for dissolution, adding 2-4% of sodium hydroxide, performing stirring reaction at a room temperature, performing solid-liquid separation, drying, roasting, and crushing to obtain the ZrN-ZrO2-SiN compound; and (2) preparation thepolishing powder for granite: adding 32-38% of the ZrN-ZrO2-SiN compound, 12-18% of oxalic acid and 12-18% of ammonium binoxalate, performing grinding and uniform mixing, adding 15-20% of ammonium fluoborate and 15-20% of stearic acid, performing grinding and uniform mixing, adding 1.0-2.0% of sodium dodecyl sulfate, and performing grinding and uniform mixing to obtain the polishing powder for granite. The polishing powder has the characteristics of chemical polishing, and has a good polishing effect, high glossiness, few scratches, and high flatness and a small usage amount, and the corrosionof oxalic acid can be buffered with the addition of the ammonium bioxalate.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com