Abrasive grain CeO2 for chemical and mechanical buffing and method for preparing same

A chemical mechanical and polishing grinding technology, which is applied in the fields of polishing compositions containing abrasives, fibrous fillers, semiconductor/solid-state device manufacturing, etc. It can solve problems such as unstable performance, poor monodispersity, and affecting the performance of abrasives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

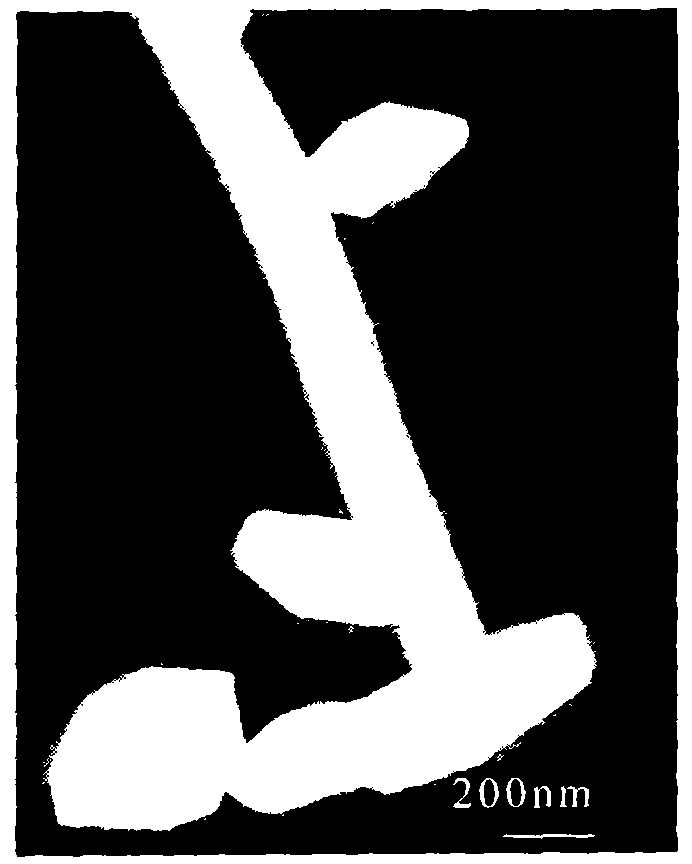

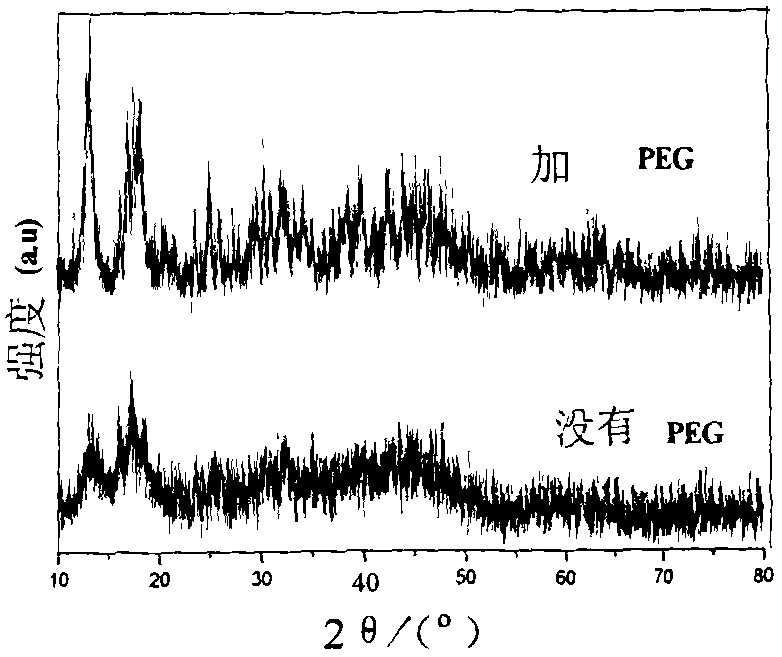

[0028] Example 1: Dissolving solid trivalent cerium salt in water to form 0.1mol L -1 solution, add dimethyl oxalate to this solution to form Ce 3+ : Dimethyl oxalate=1:8 clear mother liquor. Put it into a constant temperature water bath at 30° C. and stir continuously for several hours (testing with oxalic acid found that the reaction was not complete). The precipitate was separated by centrifugation, washed with deionized water and then with ethanol. The precipitate was dried at room temperature to obtain amorphous Ce 2 (C 2 o 4 ) 3 10H 2 O white precursor powder, the morphology of the powder was observed by TEM, and the phase structure was confirmed by XRD.

[0029] From figure 1 It can be seen from the image of the transmission electron microscope that: at low temperature, the precursor powder prepared without adding surfactant is an amorphous sample with uneven size, and the size is on the micron scale;

example 2

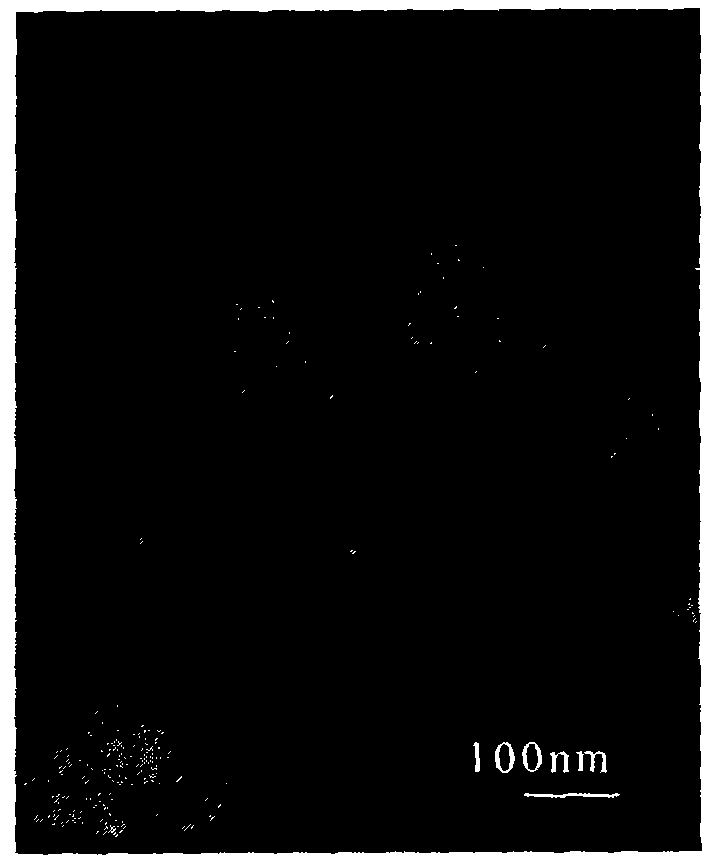

[0030] Example 2: Dissolving solid trivalent cerium salt in water to form 0.1mol L -1 solution, add dimethyl oxalate to this solution to form Ce 3+ : dimethyl oxalate=1:5 clear mother liquor, adding 1.0% by weight non-ionic surfactant polyethylene glycol 20000 (PEG20000) to this mother liquor. Put the mixed solution in an ultrasonic machine for ultrasonic treatment for 15 minutes, and then put it into a constant temperature water bath at 30° C. and stir continuously for several hours (the reaction was found to be complete by testing with oxalic acid). The precipitate was separated by centrifugation, washed with deionized water and then with ethanol. The precipitate is dried at room temperature to obtain spherical Ce 2 (C 2 o4 ) 3 10H 2 O white precursor powder, TEM observed the powder morphology, and XRD confirmed its crystallization degree; put the precursor powder in a muffle furnace and calcined at 400°C to obtain the abrasive CeO 2 Powder, its morphology was observed...

example 3

[0033] Example 3: Dissolving cerium salt in water to make 0.2mol L -1 solution, add dimethyl oxalate to this solution to form Ce 3+ : dimethyl oxalate=1:6 clear mother liquor, adding 0.8% by weight surfactant polyvinyl alcohol (PVA-124) to this mother liquor. Put the mixed solution in an ultrasonic machine for ultrasonic treatment for 10 minutes, and then put it into a constant temperature water bath at 30° C. and stir continuously for several hours (the reaction was found to be complete by testing with oxalic acid). The precipitate was separated by centrifugation, washed with deionized water and then with ethanol. The precipitate is dried at room temperature to obtain spherical Ce 2 (C 2 o 4 ) 3 10H 2 O white precursor powder, after calcination to obtain abrasive CeO 2 The powder has an average particle size of 87.53nm and a dispersion of 0.90.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com