Self-heating platform used for forming of fiber composite board

A fiber composite board, self-heating technology, applied in the field of composite material processing, can solve the problems of difficult to observe resin, opaque heating device, etc., to shorten the heating time, easy to operate, and get rid of the uneven effect of the production site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives and technical solutions of the present invention clearer, the technical solutions of the present invention will be clearly and completely described below with reference to the embodiments of the present invention.

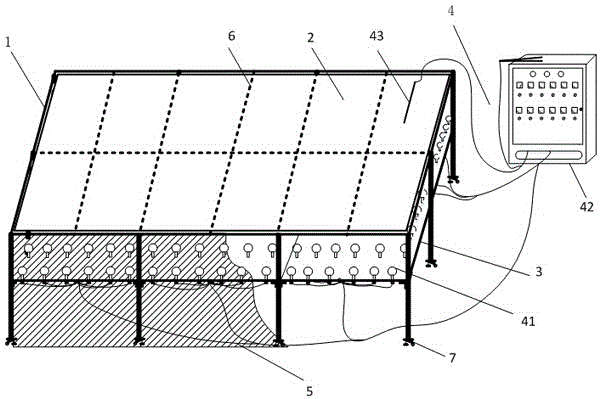

[0027] like figure 1 As shown, a self-heating platform for forming fiber composite panels includes a support device 1 , a tempered glass template 2 , a heat radiation lamp mounting base 3 , a heating device 4 and a heat preservation device 5 .

[0028] The support device 1 is a cuboid frame, the tempered glass template 2 is a rectangle, and is arranged at the top of the support device 1 , the heat radiation lamp mounting base 3 is a rectangle and has the same size as the tempered glass template 2, and the heat radiation lamp mounting base 3 is a rectangle and the same size as the tempered glass template 2. The seat 3 is arranged on the support device 1 parallel to the tempered glass template 2 and is located directly below the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com