Storage frame allowing cloth to be taken

A storage rack and cloth technology, applied in the field of storage racks, can solve problems such as waste of manpower, low efficiency, and easy safety problems, and achieve the effect of improving safety and efficiency and avoiding climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

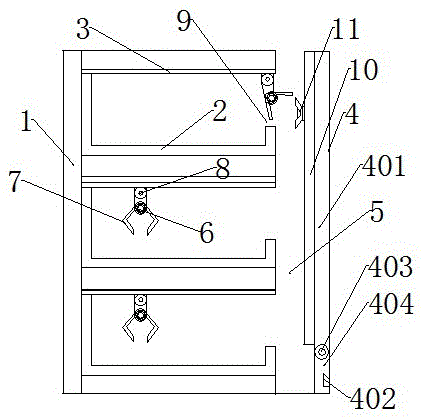

[0016] The storage rack for extracting cloth includes: shelf 1, as for the storage box 2 on the shelf 1, the grabbing component located on the storage box 2, the lateral moving part fixed on the shelf 1 and driving the grabbing component to move, located on the shelf 1 and accept the receiving component of the cloth dropped by the grasping component, the vertical channel 5 formed between the shelf 1 and the receiving component, the receiving component includes: as for the limiting wall 4 next to the shelf 1, as for the limiting wall 4 The vertical moving part is connected to the suction part of the vertical moving part. As a preference, the suction part is a vacuum suction cup 11 , the horizontal moving part is a horizontal guide rail 3 , and the vertical moving part is a vertical guide rail 10 . The grabbing assembly includes: an electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com