Running detecting system and method for conveyer belt glue peeling device

A technology of operation detection and conveyor belt, which is applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc. It can solve the problems that the rotating roller cannot run normally, the fault cannot be detected, and the motor runs normally, etc., and achieves simple structure, Loss prevention and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

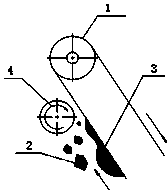

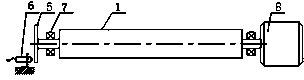

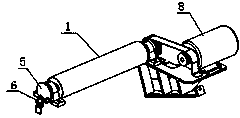

[0030] Embodiment one, refer to figure 2 and image 3 , this embodiment proposes a conveyor belt stripping device operation detection system, including a main processor, a signal plate 5 and a detection switch 6, the rotating roller 1 is fixed on the frame or other components through the bearing 7, and the driving device 8 is driven by a belt The rotary roller 1 rotates.

[0031] The signal disc 5 is installed at the end of the rotating roller 1. The signal disc 5 in this embodiment is circular, and there is a section of arc-shaped hole 5-1 at the edge of the signal disc 5. When rotating, the detection switch 6 or is facing the arc. shaped hole or facing other areas. Of course, the signal disc in this embodiment is not limited to a circle, and square, strip, semicircle or other irregular shapes may also be used.

[0032] The detection switch 6 is facing the signal disc 5 to detect the rotation signal of the detection signal disc 5 and output it to the main processor, and ...

Embodiment 2

[0036] Embodiment 2. In this embodiment, when the signal disc rotates, the alternate signal is not generated by detecting the through-hole area, but an object that can provide an alternate signal when it rotates is installed on the signal disc, such as installing a magnet on the signal disc. And use a magnetic detection switch to detect the rotation signal, such as Image 6 As shown, the detection switch is a magnetic switch, and the magnet 5-2 facing the proximity switch when rotating is installed on the signal disc 5 . Other principles are similar to Embodiment 1, and will not be repeated here.

Embodiment 3

[0037] Embodiment 3, this embodiment proposes a method for detecting the operation of a conveyor belt stripping device, including the following steps:

[0038] Step A, obtaining the rotation speed of the rotating roller through the signal disc installed on the rotating roller and the detection switch installed on the frame to detect the signal disc signal;

[0039] Step B. Comparing the rotational speed obtained in step A with the preset rotational speed to determine the operating status of the belt stripping device, and triggering an alarm when the stripping device is in a faulty state.

[0040] Step C, displaying the operating status of the stripping device through the display screen.

[0041] Of course, triggering the alarm and step C can also be selected in actual application.

[0042] The detection method of this embodiment is to directly detect the rotating roller itself, which avoids false detection and misjudgment caused by the detection of the driving device, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com