Cross beam supporting system used for tower crane

A technology of support system and beam, applied in cranes, transportation and packaging, etc., can solve the problems of poor stability, occupying a lot of steel for the structure, restricting the load of tower cranes, etc., to achieve the effect of firm support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

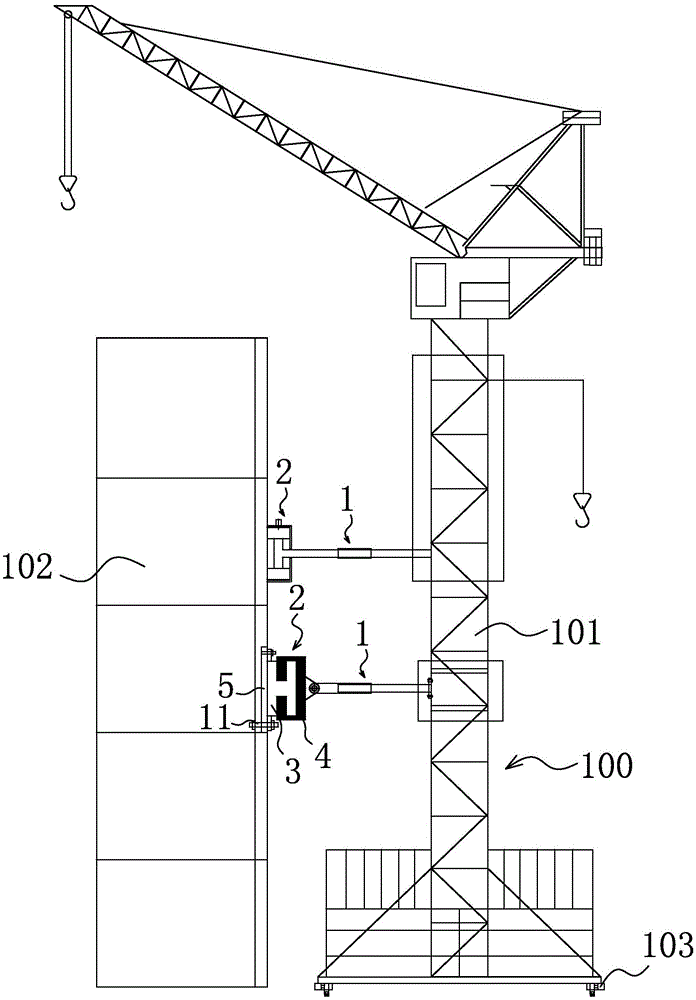

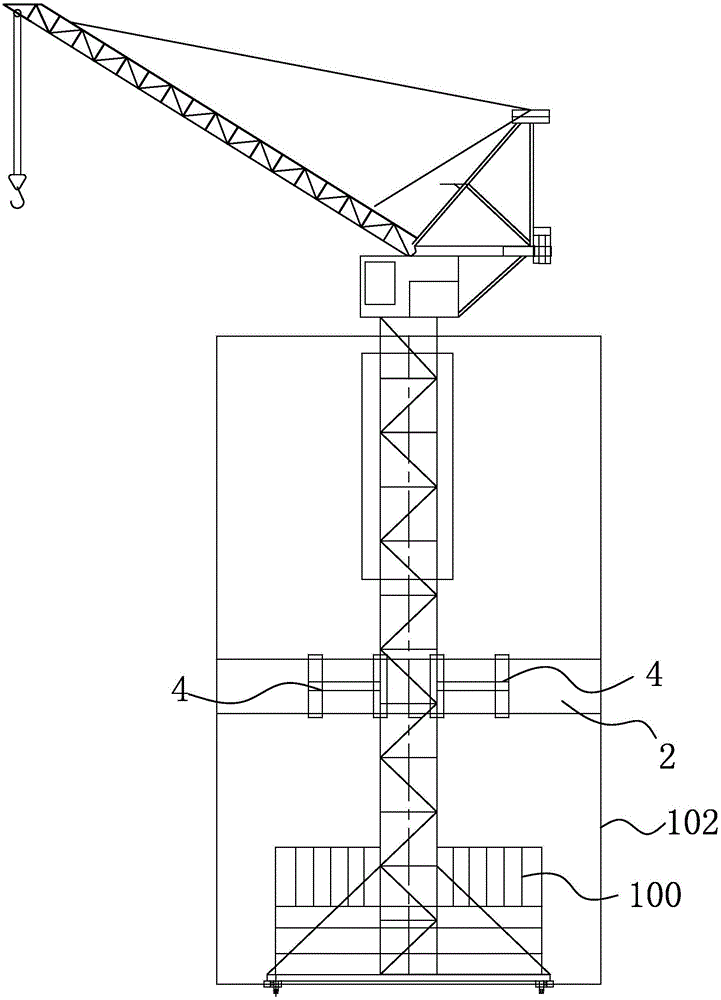

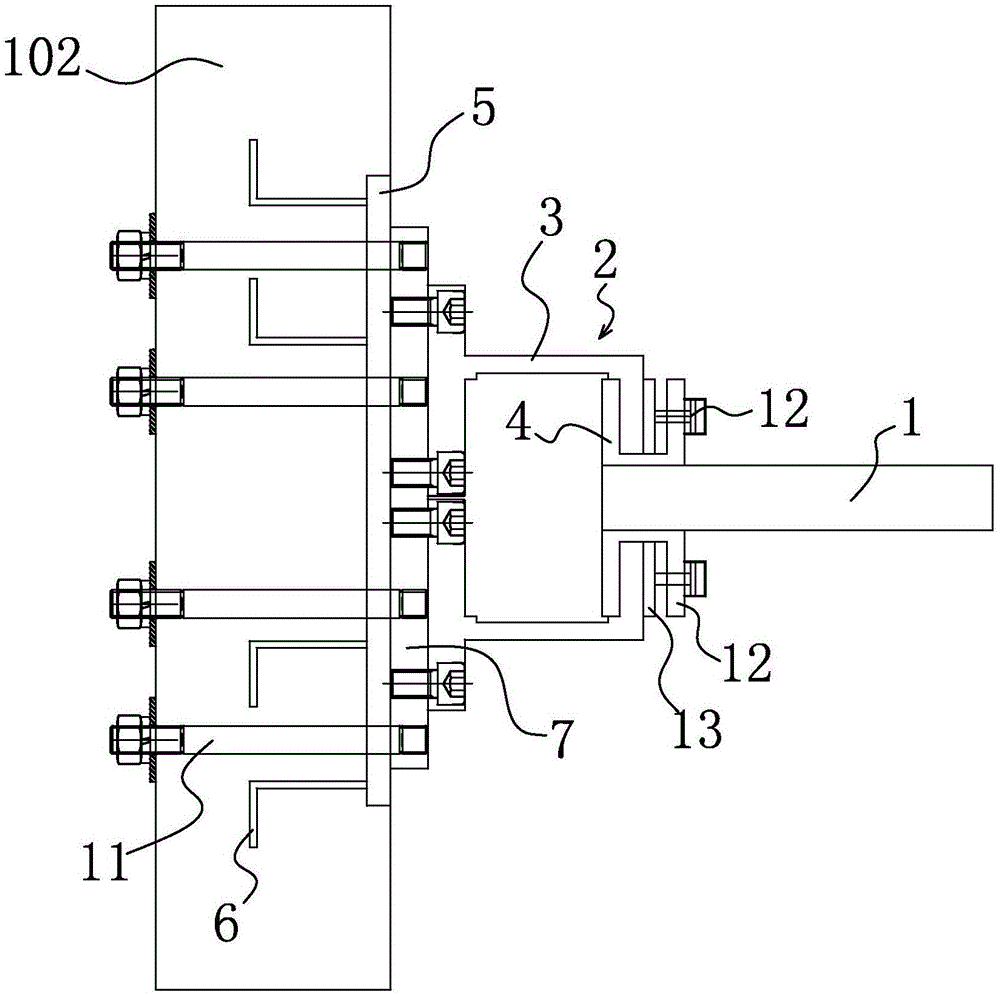

[0037] Such as figure 1 and figure 2 As shown, a beam support system for a tower crane includes a beam 1, the beam 1 is horizontally arranged and one end is fixedly connected to the tower body 101 of the tower crane 100, the tower body 101 is vertically arranged, and the other end of the beam 1 is connected to the slide rail The assembly 2 is connected, and the slide rail assembly 2 includes a slide rail 3 and a slider 4 that is compatible with the slide rail 3 and can walk along the slide rail 3. The cross section of the slide rail 3 is C-shaped or H-shaped. The sliding rail 3 is fixedly connected to the building 102, and the sliding block 4 is connected to the end of the beam 1.

[0038] The working principle of the present invention is: the beam 1 is connected with the slide rail assembly 2, the slide rail assembly 2 is fixed on the building 102, the tower crane 100 is supported by the beam 1, and the beam 1 is supported by the slide rail assembly 2 and the building 102, ...

Embodiment 2

[0045] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as Figure 7 As shown, the slide rail 3 is H-shaped, including a first panel 8, a transverse support plate 9 and a second panel 10 connected to each other, the first panel 8 and the second panel 10 are parallel to each other, and the two ends of the transverse support plate 9 are respectively connected to the first One panel 8 is fixedly connected to the second panel 10, the first panel 8 is fixedly connected to the embedded plate 5, the second panel 10 is fixed with a slider brake cylinder 12, and the slider brake cylinder 12 is connected to the brake pad 13 and made The movable piece 13 is located between the second panel 10 and the slider 4 .

[0046] This embodiment provides a detachable structure of the slide rail assembly 2, which is convenient for installation and transportation during construction.

[0047] Such as Figure 8 and Figu...

Embodiment 3

[0049] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as Figure 5 , Figure 13 and Figure 14 As shown, the crossbeam 1 is provided with an axial distance adjustment mechanism 14 capable of adjusting the length of the crossbeam 1. The crossbeam 1 includes a front arm 15 and a rear arm 16, and a sleeve 17 is sleeved on the front arm 15 and the rear arm 16 and The tubes 17 are detachably fixedly connected to the front arm 15 and the rear arm 16 respectively.

[0050] When the tower crane 100 is walking, the distance between the tower crane 100 and the slide rail assembly 2 will change, but the length of the beam 1 is fixed. Therefore, if the length of the beam 1 cannot be adjusted, the distance between the tower crane 100 and the slide rail assembly 2 will be The clamping phenomenon occurs, causing the tower crane 100 to not be able to walk normally. Therefore, this embodiment designs an axial dis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap