Fixed PET chip evenly-distributing apparatus

A polyester chip, fixed technology, used in filament forming processing, textile and papermaking, fiber processing, etc., can solve the problems of unequal proportion and fiber color difference, and achieve the effect of improving color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

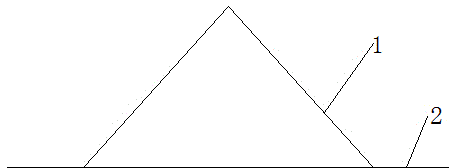

[0015] Such as figure 1 , 2 As shown, a fixed polyester chip homogenization device includes a conical dry chip silo, a conical distributor 1 and a bracket 2. The conical distributor is fixed on the bracket. The conical distributor is welded to the bottom center of the dry chip silo through a bracket.

[0016] The conical distributor has a cone angle of 42°.

[0017] The conical distributor has a surface area of 0.34 m2.

[0018] Conical distributors are conical distributors with polished and deburred surfaces.

[0019] The bracket is a bracket with surface polishing and deburring.

[0020] Conical distributor material is 304 stainless steel.

[0021] The bracket material is 304 stainless steel.

[0022] The invention is placed in the middle of the conical bottom of the dry chip silo above the spinning screw extruder, and shunts the polyester chips coming down from the center of the silo to the surroundings to achieve the function of homogenizing the materials.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com