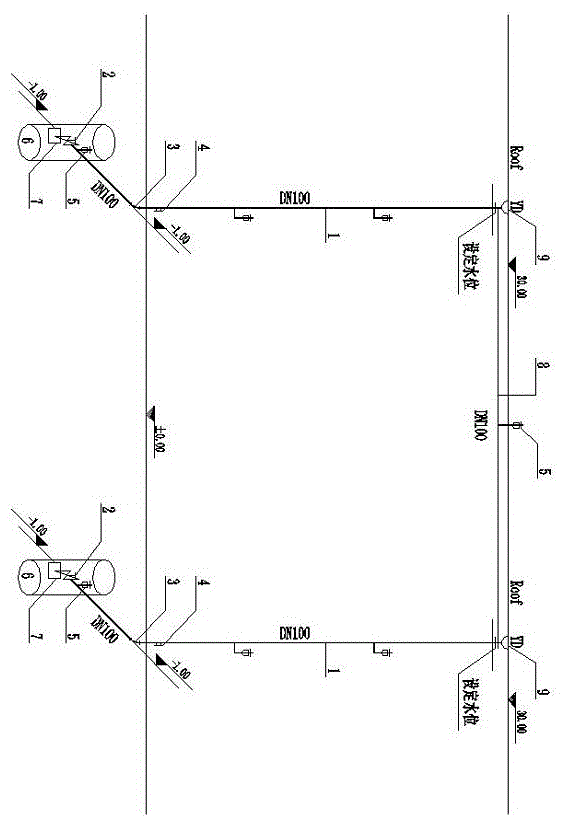

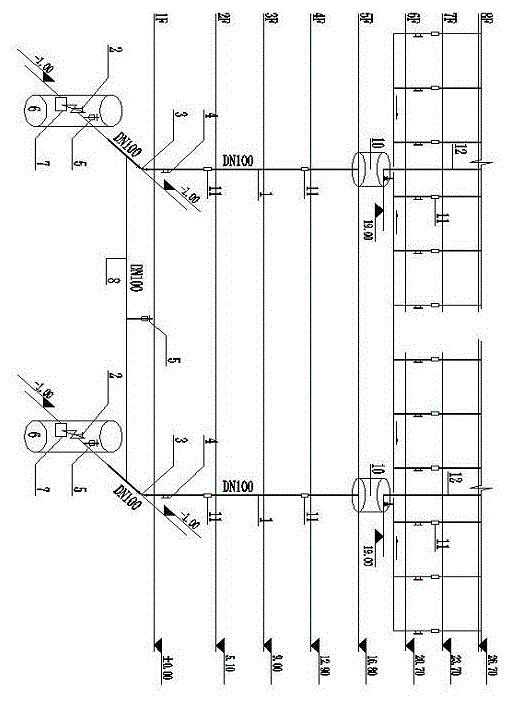

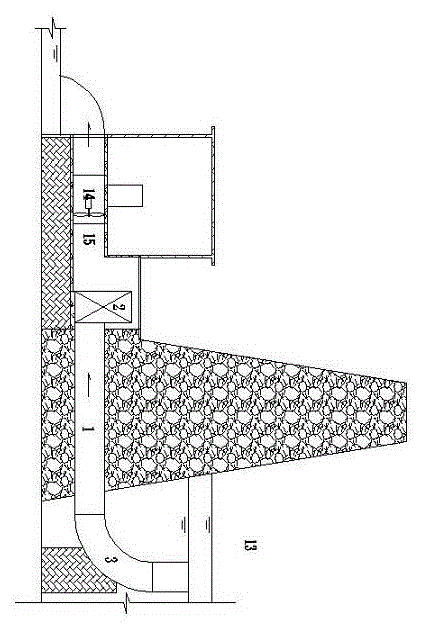

Intermittent pressure flow drainage system

A drainage system and pressure flow technology, applied in the field of innovation and invention, can solve the problems of inability to achieve pressure flow drainage, irregular drainage, and flow interruption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0077] The specific resistance of the steel pipe adopted in the specific embodiment one is 267.4, the length of a single system pipe is 35 meters, and the water level difference between inlet and outlet is set to be 30 meters, so Q=(30 / 267.4*35) 1 / 2 =0.0566 (cubic meter / second), that is, 56.6 liters / second. This flow rate is the maximum flow rate of the system, and it is also the design flow rate of a single system, which meets the rainwater discharge requirements, and the corresponding flow rate is 7.22 m / s. The average flow rate is 28.3 liters / second and the average flow rate is 3.61 m / s, which meets the requirement of metal pipes with a flow rate of less than 10 m / s. In view of the fact that the average flow rate is much greater than the economic flow rate, it may be considered to add a small hydroelectric generator in the inspection well as an energy dissipation measure. Because the rainwater has few impurities, it is also conceivable to set up a micro-hydraulic generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com