Arrangement and Installation Method of Marine Diesel Engine Anchor Bolts on Test Bench

A marine diesel engine and anchor bolt technology, which is applied to the frame of the engine, special foundation layout, supporting machines, etc., can solve the problems of high labor intensity, difficult layout operation, and consumption of auxiliary materials for operators, and saves time for cleaning and finishing work. , The effect of solving the complex and difficult layout and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Arrange and install the anchor bolts of the marine diesel engine on the test bench according to the following specific steps:

[0036] 1. Install some test iron benches on the test bench.

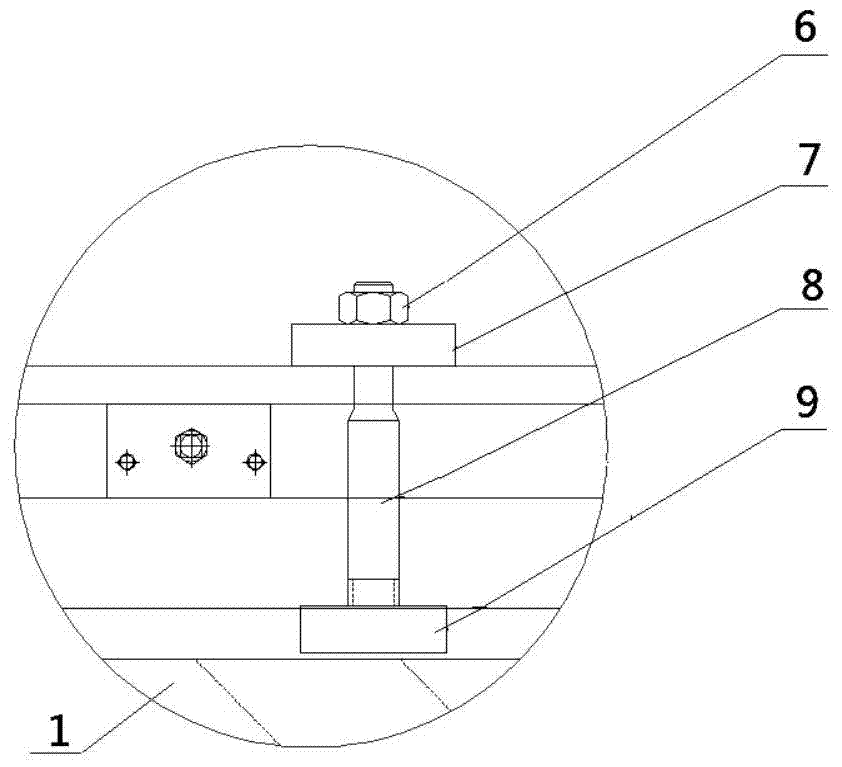

[0037] The test run iron bench 1 is a general test run iron bench, and its structure is determined according to the production plan and in combination with the actual platform layout. The general test run iron bench 1 is provided with a plurality of inverted T-shaped grooves.

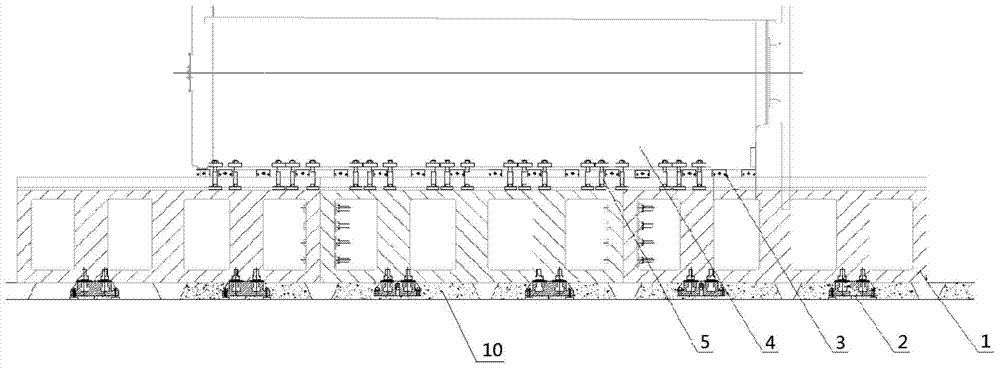

[0038] see figure 1 According to the iron bench layout diagram of the test bench, a number of iron benches 1 are laid out flatly on the test bench 10. The several iron benches 1 are fixedly connected to each other on the sides, and the bottom surface thereof is fastened to the table surface of the test bench 10 through fasteners 2. superior.

[0039] 2. Arrange the position of the anchor bolts of the marine diesel engine.

[0040] Firstly, process digestion of the shafting arrangement of the main engine of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com