Heat recovery fresh air machine

A new fan, heat recovery technology, applied in space heating and ventilation, space heating and ventilation details, ventilation and heating energy recovery systems, etc., can solve energy waste, poor ventilation, short heat exchange time, etc. To improve the utilization rate of waste heat, eliminate dead ends of heat exchange, and achieve good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be described in detail below with reference to the drawings, but the invention is not limited to the following examples.

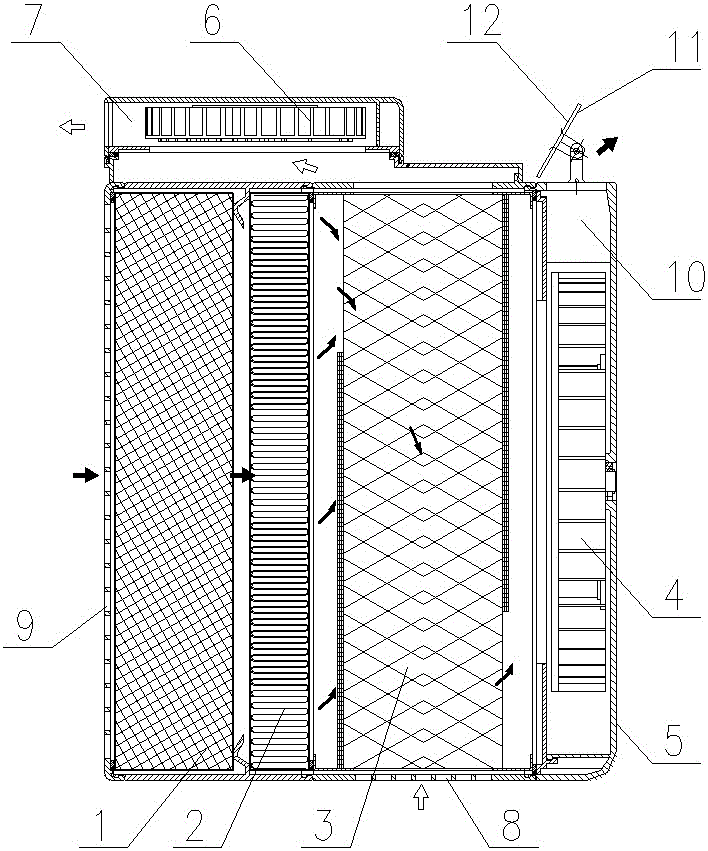

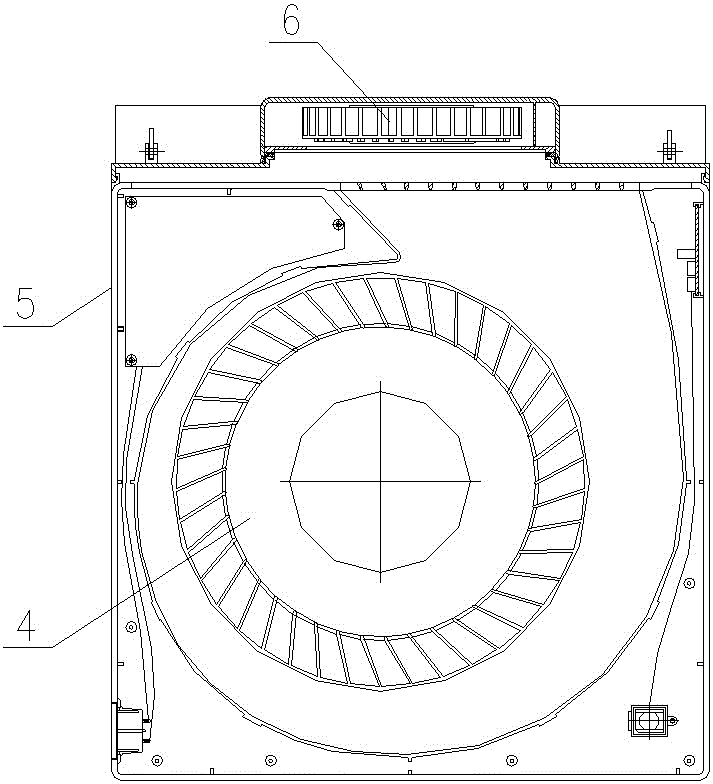

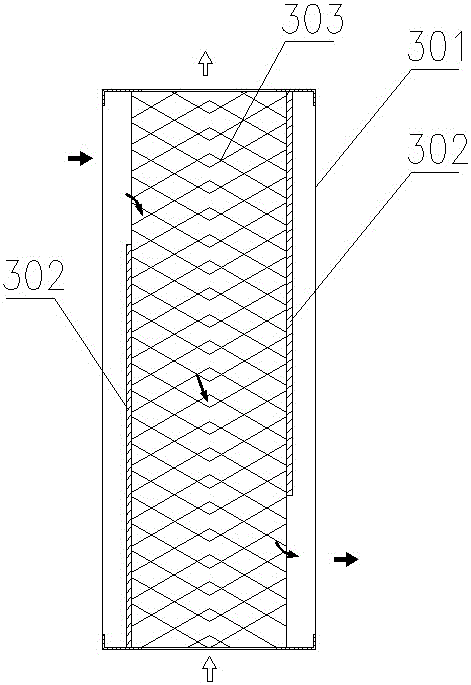

[0018] Such as figure 1 , figure 2 As shown, a fresh heat recovery fan includes a casing 5, a primary filter 1, a high efficiency filter 2, a plate heat exchanger 3, a blower 4, and an exhaust fan 6. The casing 5 is made of non-metallic materials such as metal or plastic, artificial board, etc., and the primary filter 1, the high efficiency filter 2, the plate heat exchanger 3, and the blower 4 are installed in the casing 5 in parallel in turn. After the fresh air enters from the fresh air inlet 9 of the casing 5, it passes through the primary filter 1, the high-efficiency filter 2, the plate heat exchanger 3, and the blower 4 arranged in parallel successively, and then sends out from the fresh air outlet 7. The outlet of the air blower 4 is also provided with an air regulating frame 11, and the air regulating frame 11 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com