Removing and drying device for water spots on glass surface

A glass surface and drying device technology, applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of uneven coating, reduce coating quality, coating mottled, etc., achieve high cleaning efficiency, easy operation, Cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

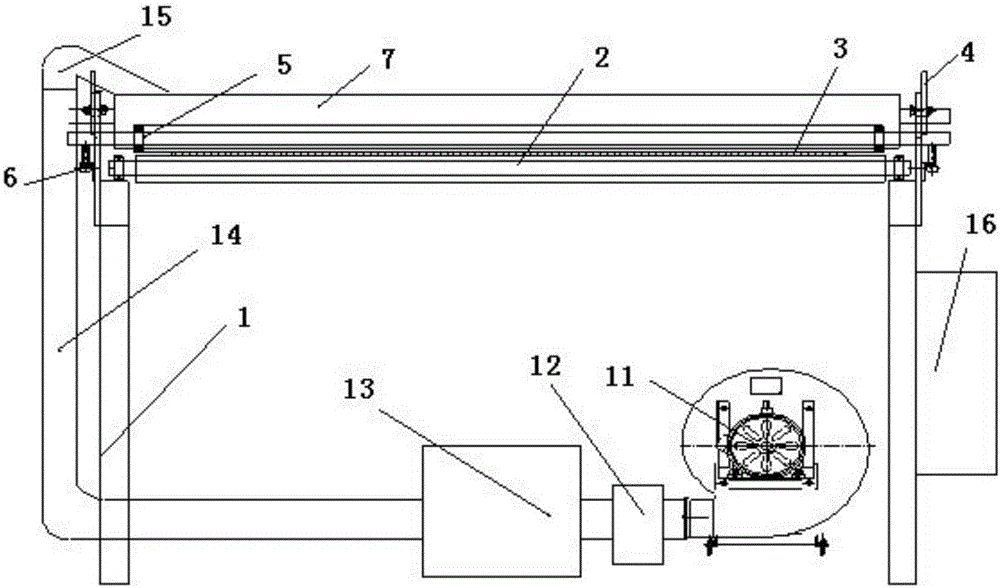

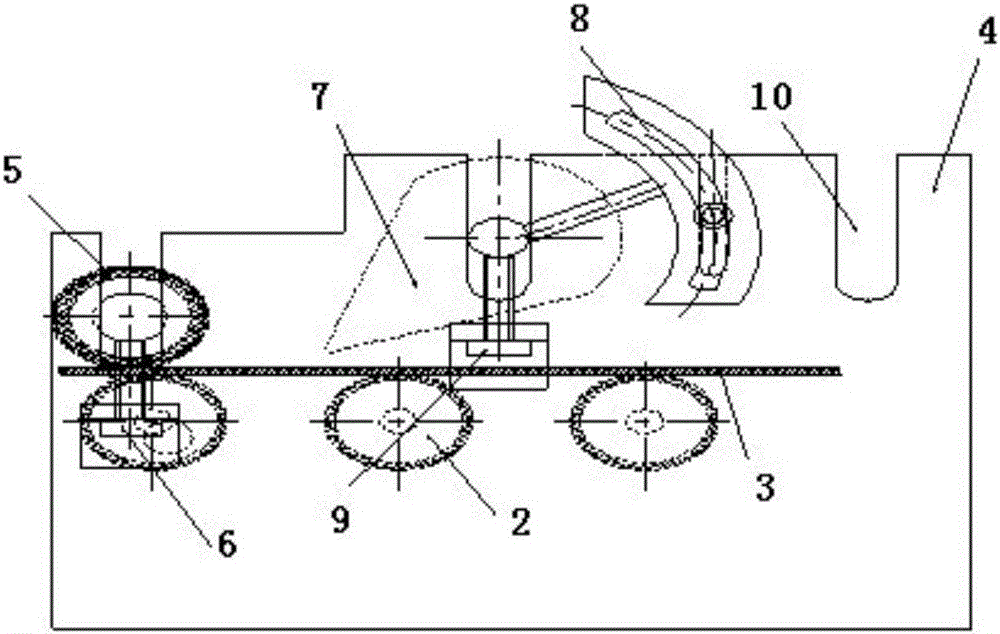

[0030] see figure 1 , figure 2 , the invention is a glass surface water spot removal and drying device,

[0031] It includes a transmission roller frame 1, on which a glass transmission roller 2 is arranged, and a flat glass 3 is placed on the glass transmission roller 2, and the glass transmission roller 2 can rotate, and drives the flat glass 3 from forward to After moving horizontally,

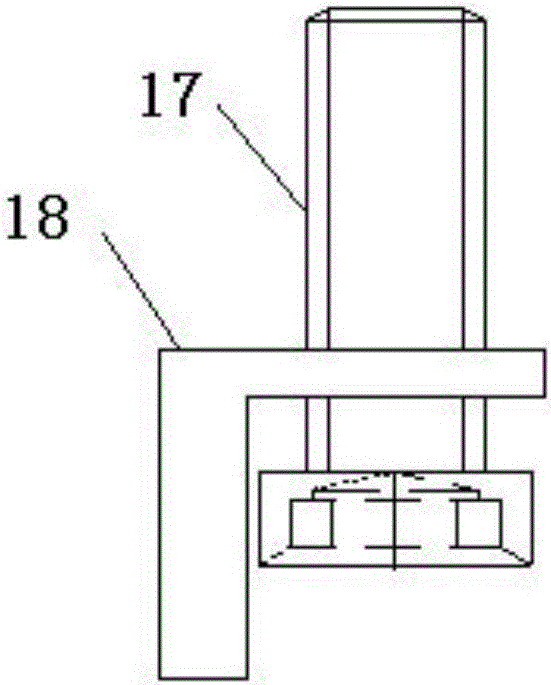

[0032] The top of the conveying roller frame 1 is provided with a fixed bracket 4, and the front end of the fixed bracket 4 is equipped with a cloth-wrapped rubber roller 5 through a rubber roller up-and-down adjustment mechanism 6, and the cloth-wrapped rubber roller 5 is located above the flat glass 3 and can be fixed Free rotation on the support 4, the rubber roller up and down adjustment mechanism 6 can adjust the height between the cloth rubber roller 5 and the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com