Automobile shock absorber performance test method and automobile shock absorber performance test system

A test system and test method technology, applied in the field of testing, can solve the problem that the performance test results of the shock absorber cannot accurately reflect the real performance of the shock absorber, and achieve the effect of accurate and real performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the prior art, the performance test of the vehicle shock absorber is generally carried out on a shock absorber test bench. However, this kind of vibration damping performance test can only simulate the actual working conditions of the shock absorber as much as possible, and the vibration source is artificially manufactured for vibration damping test. There is still a certain difference between the simulated working conditions and the actual working conditions of the shock absorber, so that the results of the shock absorber performance test cannot truly and accurately reflect the performance of the shock absorber.

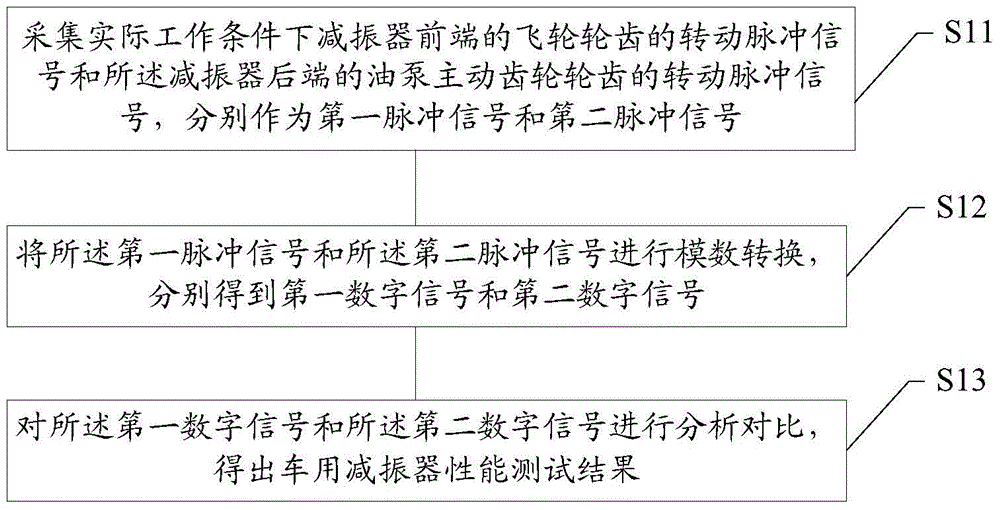

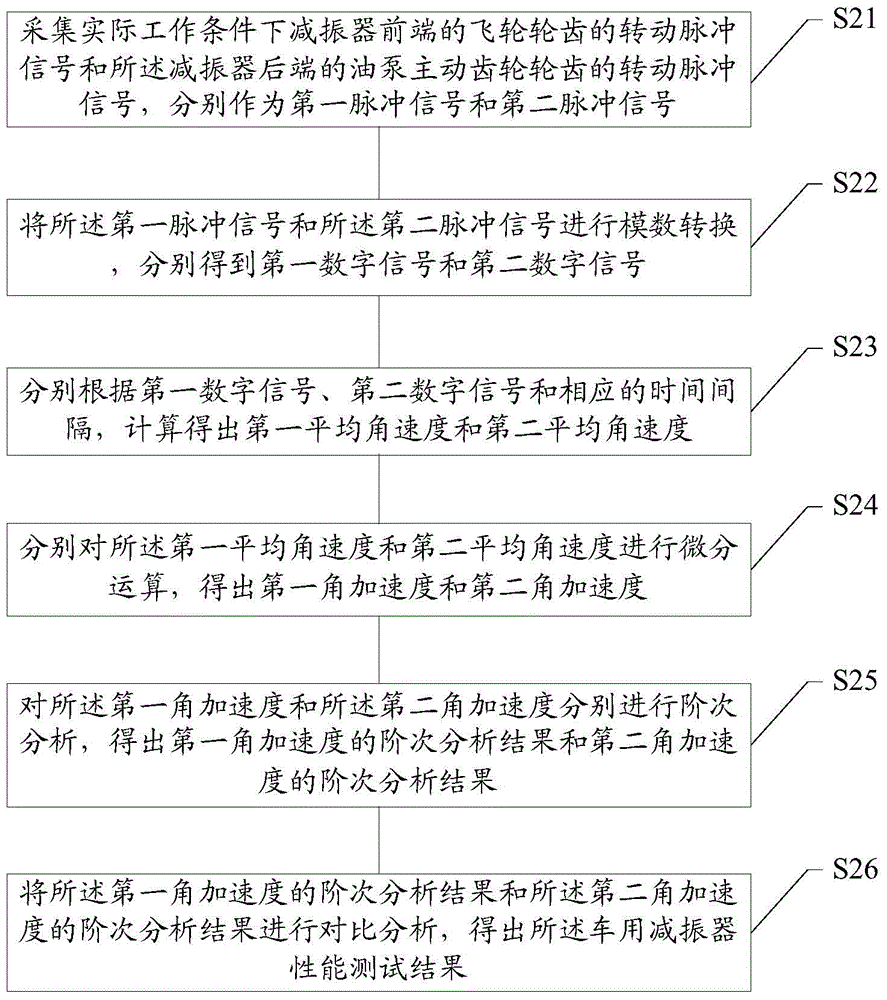

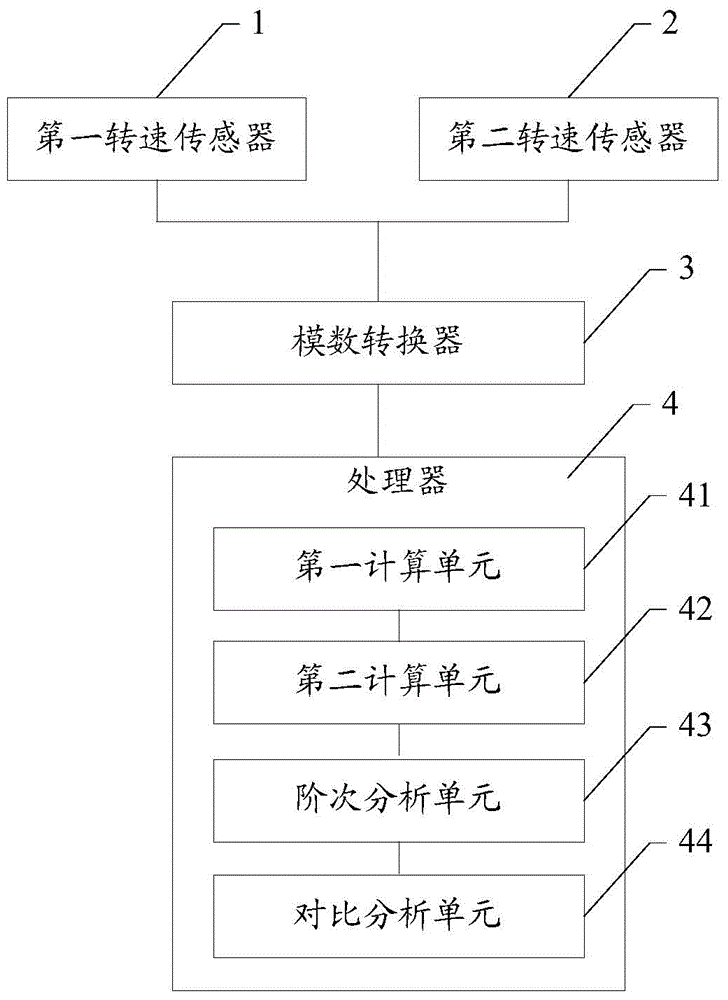

[0037] Another way is to test the performance of the shock absorber on the whole vehicle. In this way, the power transmission path of the engine is selected as the engine-flywheel-shock absorber-clutch driving disc-clutch driven disc-gearbox input shaft, and the aforementioned The rotation pulse signal of the gear teeth at the front and rear ends of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com