Method for predicting green brick tea raw material pile fermentation degree through near infrared spectrometer scanning

A near-infrared spectrometer and near-infrared spectroscopy technology, which is applied in the direction of material analysis, instruments, and measuring devices through optical means, can solve the problems of large subjectivity and randomness, and achieve non-destructive identification, improve detection accuracy, and accurate identification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0032] (1) Selection of green brick tea raw materials

[0033] Select green brick tea raw materials of 0 days, 2 days, 4 days, 7 days, 10 days, 13 days, 16 days, 19 days, 22 days and 25 days respectively, and use a pulverizer to crush the samples, and then scan the near-infrared spectrum .

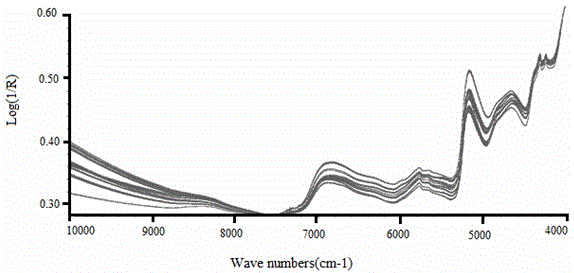

[0034] (2) Near-infrared spectrum scanning of green brick tea raw material samples

[0035] First, place the near-infrared spectrometer indoors, keep the indoor temperature at 20-25°, and keep the humidity at 30%-50%, and preheat the near-infrared spectrometer for more than 1 h. Specifically, the American Thermo Fisherman Antaris II Fourier near-infrared spectrometer was used, and an integrating sphere diffuse reflectance optical platform was used for the measurement. The spectral scanning range of the near-infrared spectrometer is 4000 cm -1 ~ 10000cm -1 , the resolution is 8cm -1 , the detector is InGaAs.

[0036] see figure 1 , and then use the near-infrared spectrometer to scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com