General test device

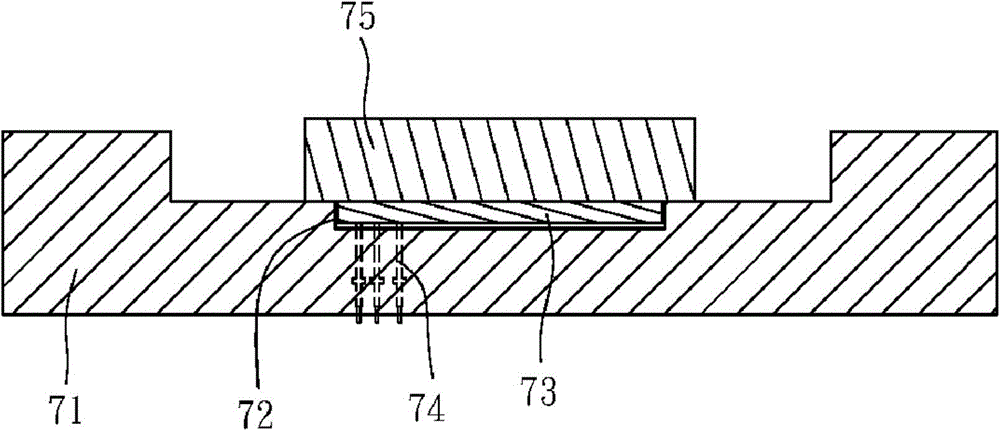

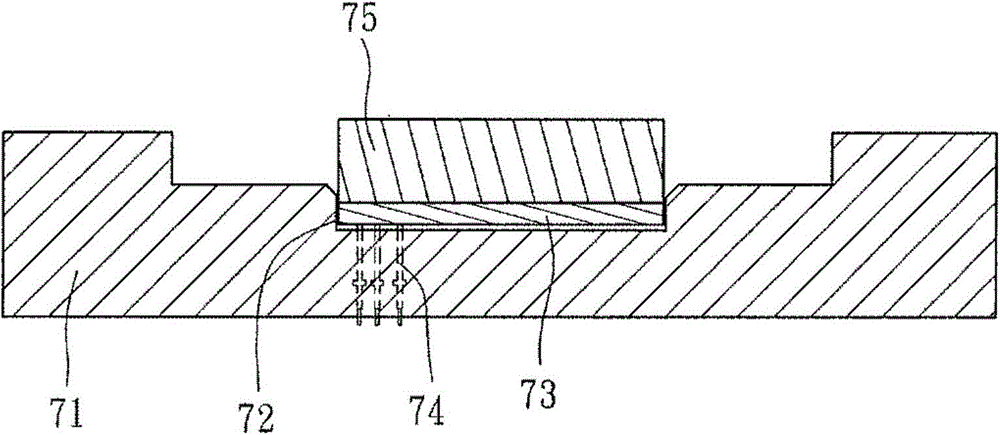

A general-purpose test and test slot technology, applied in the direction of the measuring device casing, etc., can solve the problems that the size and weight of the pressure block 75 cannot be integrated, excessive pressure, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

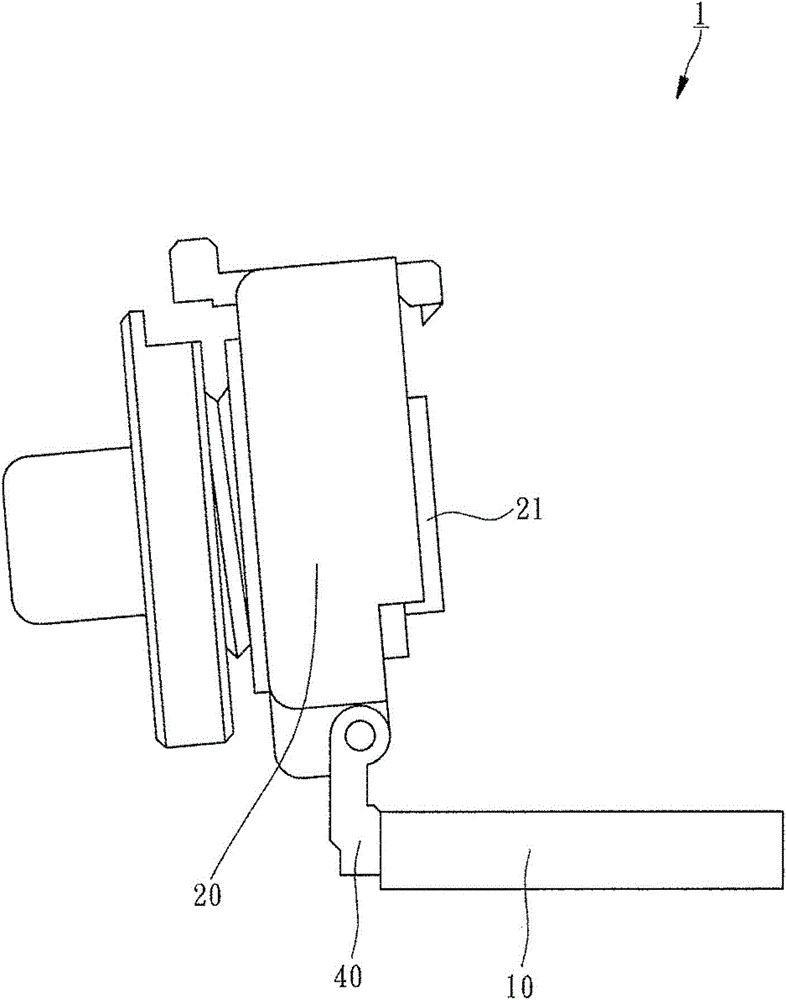

[0032] In order to better understand the characteristics of the present invention, the present invention provides a preferred embodiment, which is described as follows in conjunction with the accompanying drawings, please refer to Figure 3 to Figure 5 .

[0033] Universal testing device 1 of the present invention is used for testing object under test, and object under test is SiP module (System in Package, system-in-package module) in the present embodiment, and it also can be SoC module (System on Chip, system chip) ) or other forms of analytes, but not limited to this embodiment. The main components of the universal testing device 1 of the present invention include a carrier plate 10, a pressure head 20 and a plurality of elastic positioning members 30 (six in this embodiment), the structure of each component and the relationship between them are described in detail as follows.

[0034] Please refer to Figure 4 1, the central recess of the carrier plate 10 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com