Manufacturing method of brasque used for smelting metal chromium

A manufacturing method and metal chrome technology are applied in the field of manufacturing furnace linings used for metal chrome smelting, which can solve problems such as affecting the quality of metal chrome products, damage to magnesia bricks that cannot be reused, reducing smelting recovery rate, etc. The effect of cost reduction and difficulty in running the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

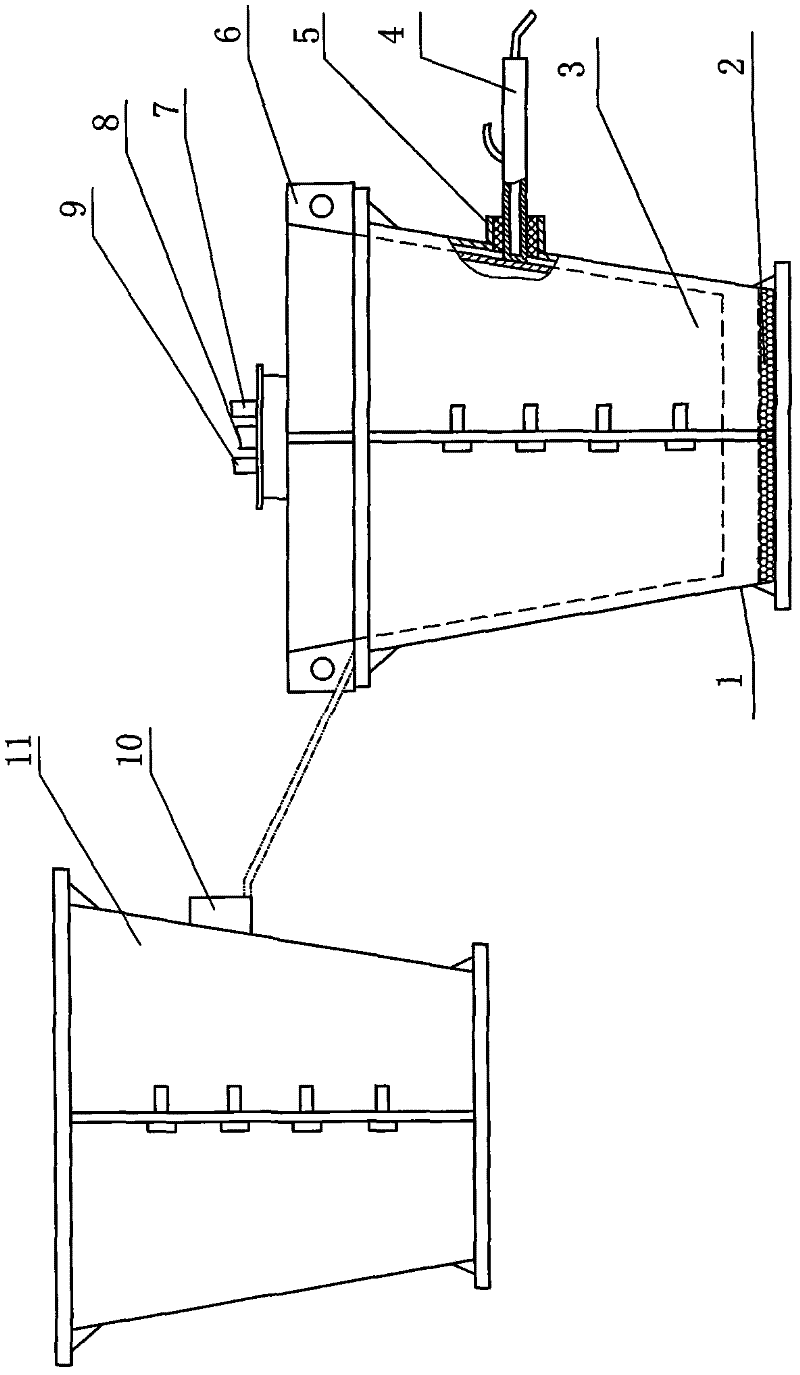

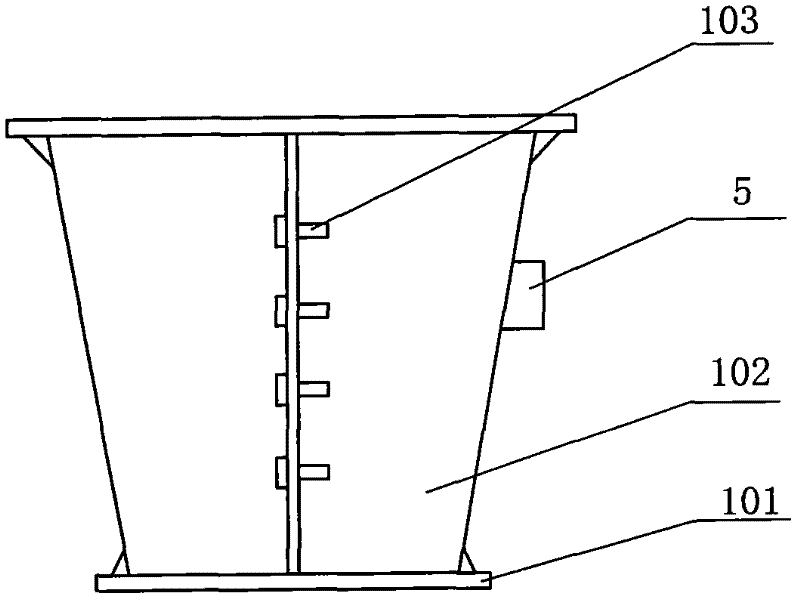

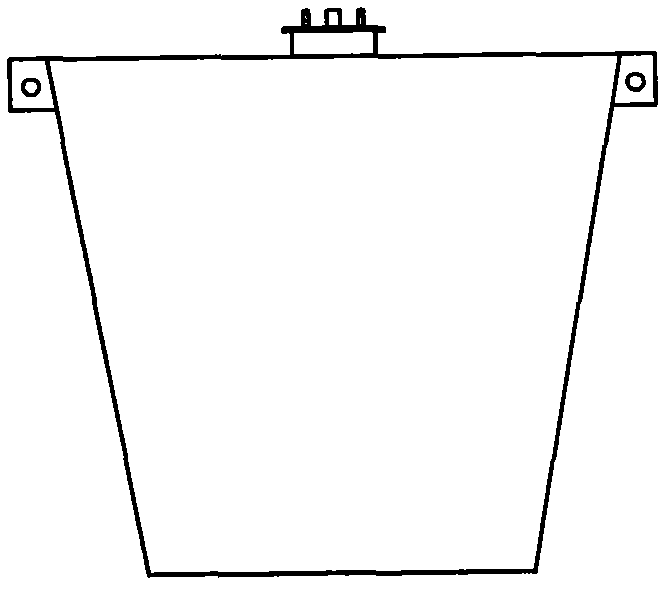

[0019] Put a pair of semicircular arc-shaped ball mill cast iron furnace pieces 102 on the metal (material can be iron plate, steel plate) chassis 101, the furnace pieces 102 are tightly aligned and sit upright, and the furnace shell 1 is formed after the pins 103 are tightened; 1. A slag outlet 5 is set at a height of 1 / 3 of the upper edge of the furnace plate 102. The cooling water jacket 4 is inserted at the slag outlet 5, and the bottom of the furnace shell 1 is supplemented with magnesia 2, and the thickness of the magnesia 2 is 100mm; The top is provided with the water inlet pipe 9, the water outlet pipe 7 and the steam outlet pipe 8, and the water tire 3 with the seat lugs 6 on both sides is seated in the middle of the furnace shell 1, so that a cavity is formed between the furnace shell 1 and the water tire 3, and Make the cooling water jacket 4 lean against the water tire 3, block the slag discharge port 5 with refractory mud, connect the water tire 3 with the external...

Embodiment 2

[0021] Put a pair of semicircular arc-shaped ball mill cast iron furnace pieces 102 on the metal (material can be iron plate, steel plate) chassis 101, the furnace pieces 102 are tightly aligned and sit upright, and the furnace shell 1 is formed after the pins 103 are tightened; 1. A slag outlet 5 is set at a height of 1 / 3 of the upper edge of the furnace 102, and a cooling water jacket 4 is inserted at the slag outlet 5, and the bottom of the furnace shell 1 is supplemented with magnesia 2, and the thickness of the magnesia 2 is 130mm; The top is provided with the water inlet pipe 9, the water outlet pipe 7 and the steam outlet pipe 8, and the water tire 3 with the seat lugs 6 on both sides is seated in the middle of the furnace shell 1, so that a cavity is formed between the furnace shell 1 and the water tire 3, and Make the cooling water jacket 4 lean against the water tire 3, block the slag outlet 5 with refractory mud, connect the water tire 3 with the external pool throug...

Embodiment 3

[0023] Put a pair of semicircular arc-shaped ball mill cast iron furnace pieces 102 on the metal (material can be iron plate, steel plate) chassis 101, the furnace pieces 102 are tightly aligned and sit upright, and the furnace shell 1 is formed after the pins 103 are tightened; 1. A slag outlet 5 is set at a height of 1 / 3 of the upper edge of the furnace plate 102, and a cooling water jacket 4 is inserted at the slag outlet 5, and the bottom of the furnace shell 1 is supplemented with magnesia 2, and the thickness of the magnesia 2 is 150mm; The top is provided with the water inlet pipe 9, the water outlet pipe 7 and the steam outlet pipe 8, and the water tire 3 with the seat lugs 6 on both sides is seated in the middle of the furnace shell 1, so that a cavity is formed between the furnace shell 1 and the water tire 3, and Make the cooling water jacket 4 lean against the water tire 3, block the slag discharge port 5 with refractory mud, connect the water tire 3 with the extern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com