Combine harvester

The technology of a combine harvester and a harvesting device is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., and can solve the unbalanced lifting force of the left and right ends of the second lawn mower and the tendency of the second lawn mower to move to the left and right Tilting and other issues can be improved to achieve the effect of improving maintenance workability and balancing lifting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

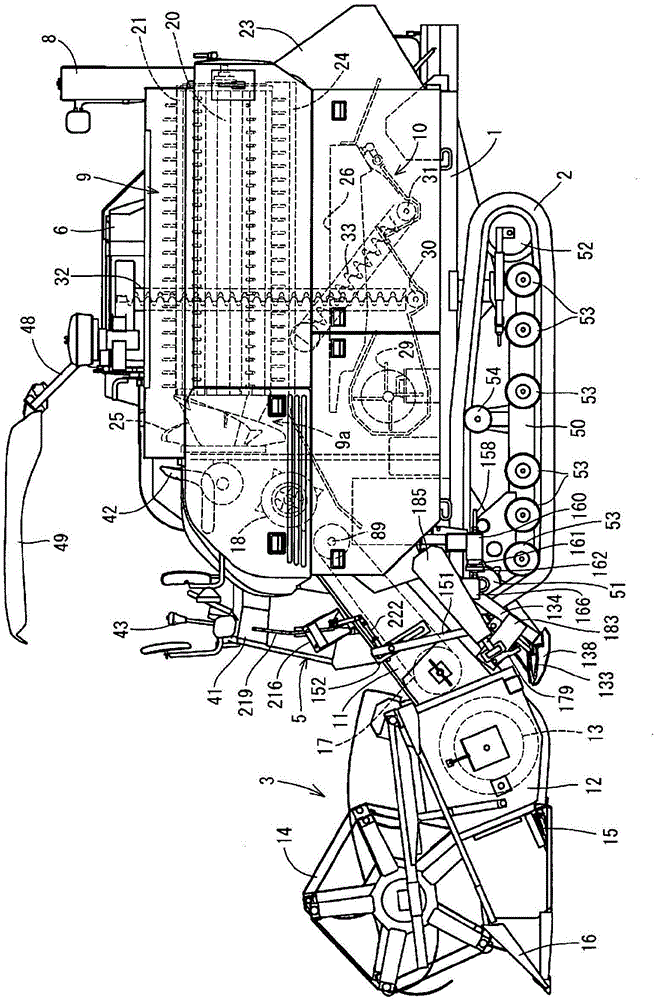

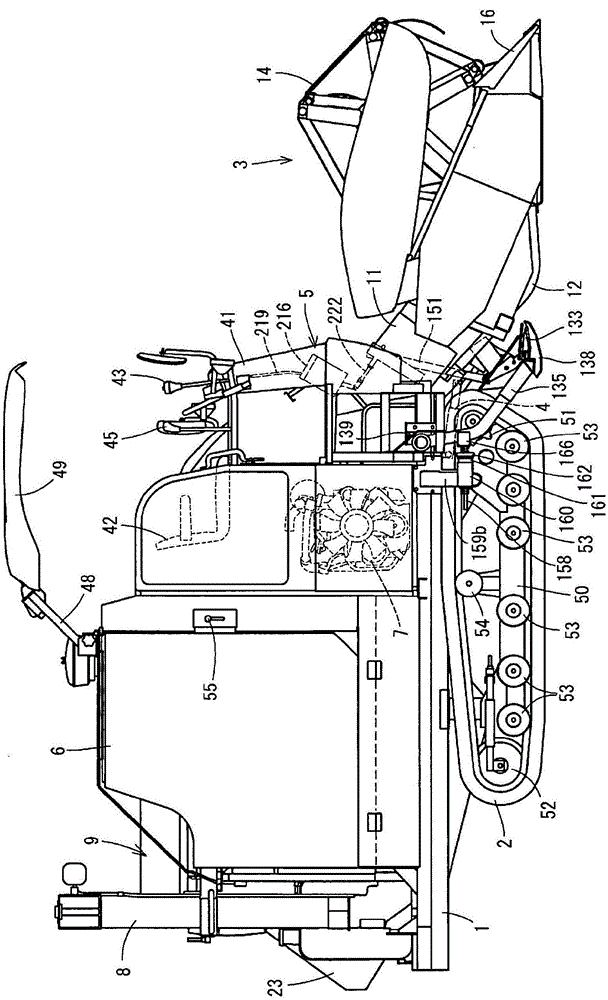

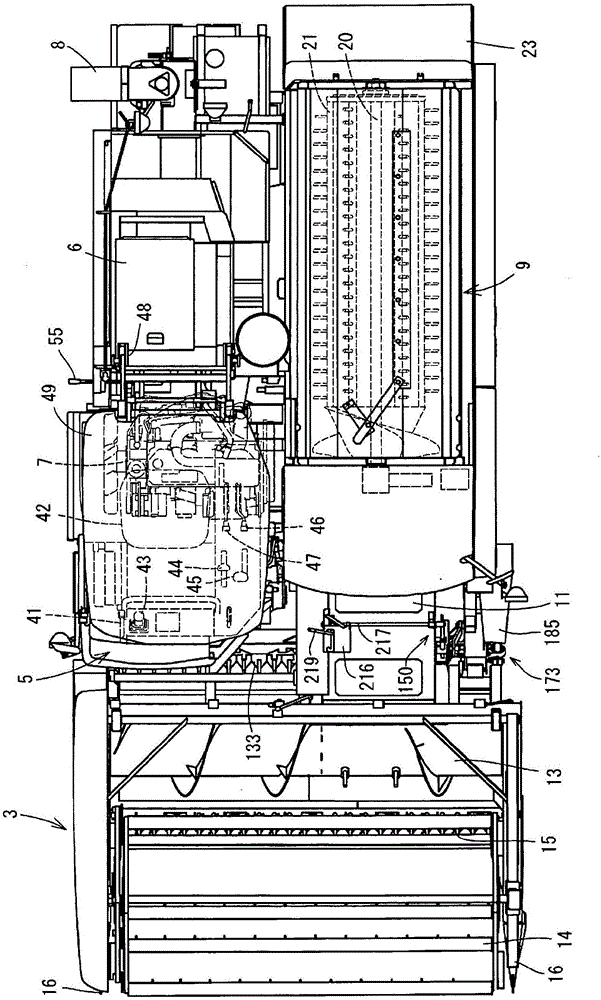

[0053] Below, based on the graph for a common type combine ( Figure 1 to Figure 4 ) to describe the embodiment of the present invention. figure 1 is the left side view of the combine harvester, figure 2 is the right side view of the combine harvester, image 3 is a top view of the combine harvester, Figure 4 It is the left perspective view of the combine harvester. First, refer to Figure 1 ~ Figure 3 The schematic structure of a combine harvester is demonstrated. In addition, in the following description, the left side when facing the advancing direction of the traveling body 1 is simply called the left side, and the right side when facing the advancing direction of the traveling body 1 is simply called the right side.

[0054] like Figure 1 ~ Figure 3 As shown, the common type combine harvester of embodiment is provided with the traveling body 1 supported by the right and left pair of crawlers 2 made of the rubber crawler which is a traveling part. On the front po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com