Precise and efficient capsule filling machine

A technology for filling machines and capsules, which is applied in capsule delivery, drug delivery, and pharmaceutical formulations, etc. It can solve the problems of inaccurate drug dosage and low capsule filling quality, and achieve high production efficiency and reduced labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

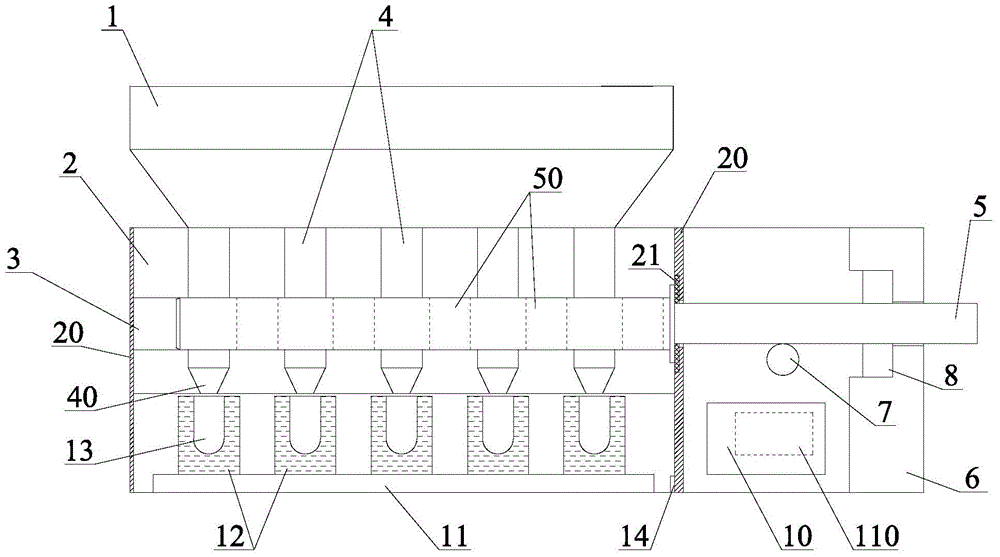

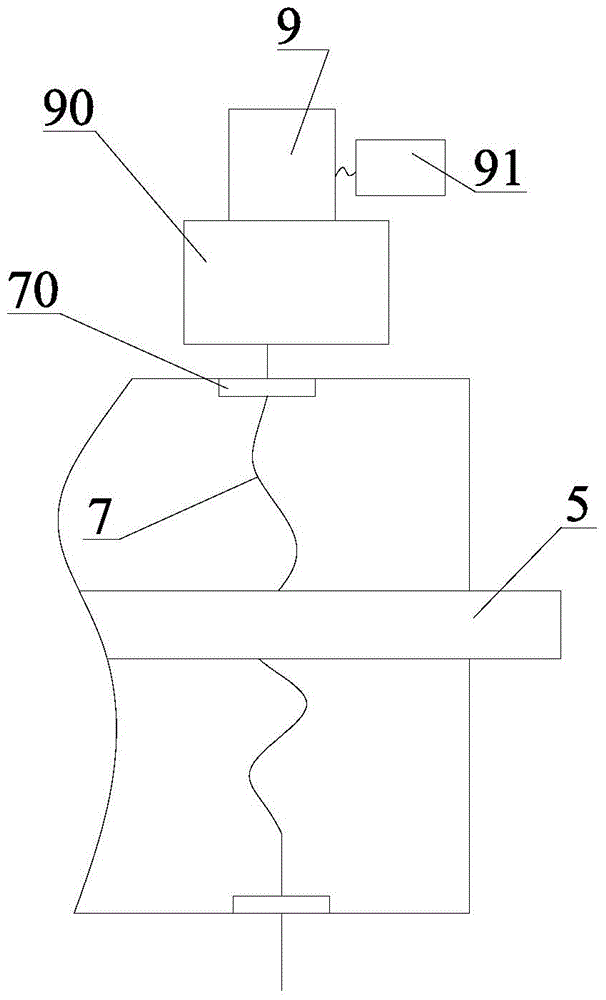

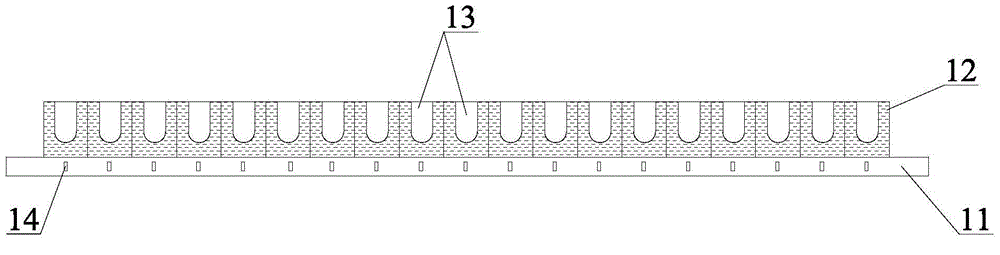

[0016] refer to figure 1 , figure 2 and image 3 , a precision and high-efficiency capsule filling machine of the present invention, comprising a feeding hopper 1, a machine base 2, a feeding channel 4, a transmission shaft 5, a ball screw 7, a motor 9, and a slide rail 11, and the feeding hopper 1 is installed on the machine base 2, a blanking channel 4 is provided on the vertical direction of the base 2, and a transmission channel 3 is provided on the horizontal direction of the base 2, and the transmission channel 3 is installed in cooperation with the transmission shaft 5, and the transmission A channel opening 50 is provided on the shaft 5, and the right end of the transmission shaft 5 is installed in cooperation with the sliding block 8. The sliding block 8 is installed on the machine base 2, and the transmission shaft 5 is engaged with the ball screw 7 for transmission. The ball screw 7 passes through the machine base 2, and is fixedly installed by the bearings 70 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com