High-pressure pump for internal combustion engines

A technology of high-pressure pumps and internal combustion engines, applied in fuel injection pumps, mechanical equipment, engine components, etc., can solve problems such as power loss and high current, and achieve the effect of reducing energy consumption and control energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

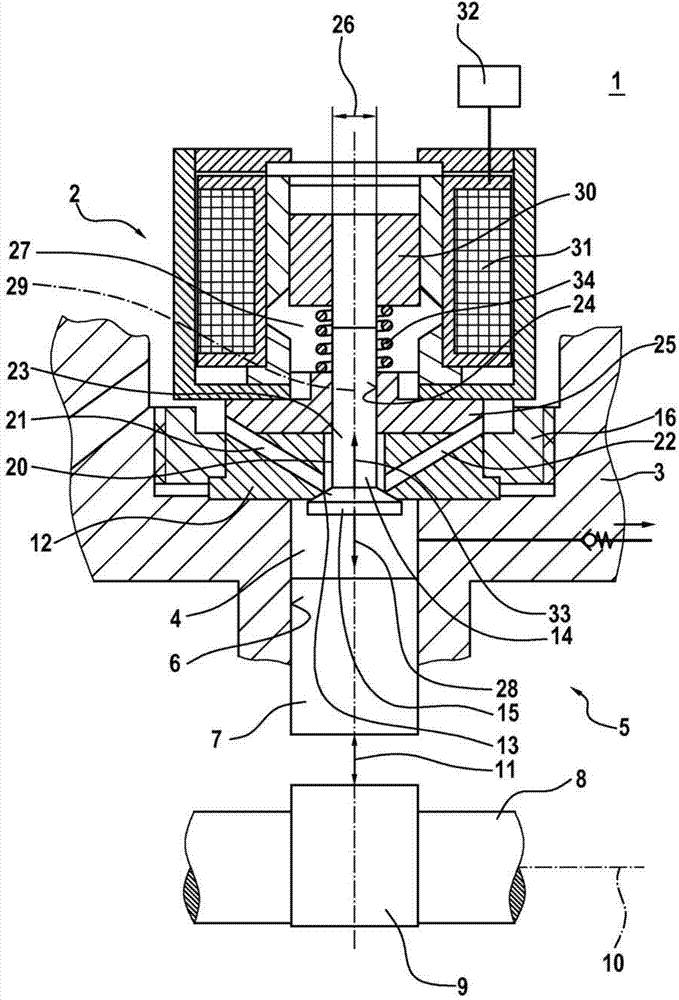

[0017] figure 1 A high-pressure pump 1 according to an exemplary embodiment of the invention is shown in a partially schematic sectional view. In particular, the high-pressure pump 1 can be designed as a radial piston pump or as a series piston pump. The high-pressure pump 1 is particularly suitable as a fuel pump for a fuel injection system of an air-compressed, self-igniting internal combustion engine. The high-pressure pump 1 has a suction valve 2 . The suction valve 2 is particularly suitable for use in such a high-pressure pump 1 . However, the suction valve 2 according to the invention is also suitable for other applications with correspondingly adapted changes.

[0018] A preferred application of the high-pressure pump 1 and the suction valve 2 is in a fuel injection system having a fuel distribution rail which stores diesel fuel under high pressure. However, other suitable fluids, ie other fluids as fuel, can also be controlled by the intake valve 2 and delivered b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com