System and method for valve seat injection

A valve seat and valve technology, which is applied in the direction of charging system, fuel injection device, fuel injection control, etc., can solve the problems of engine packaging, high cost of engine, and increase of engine outline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

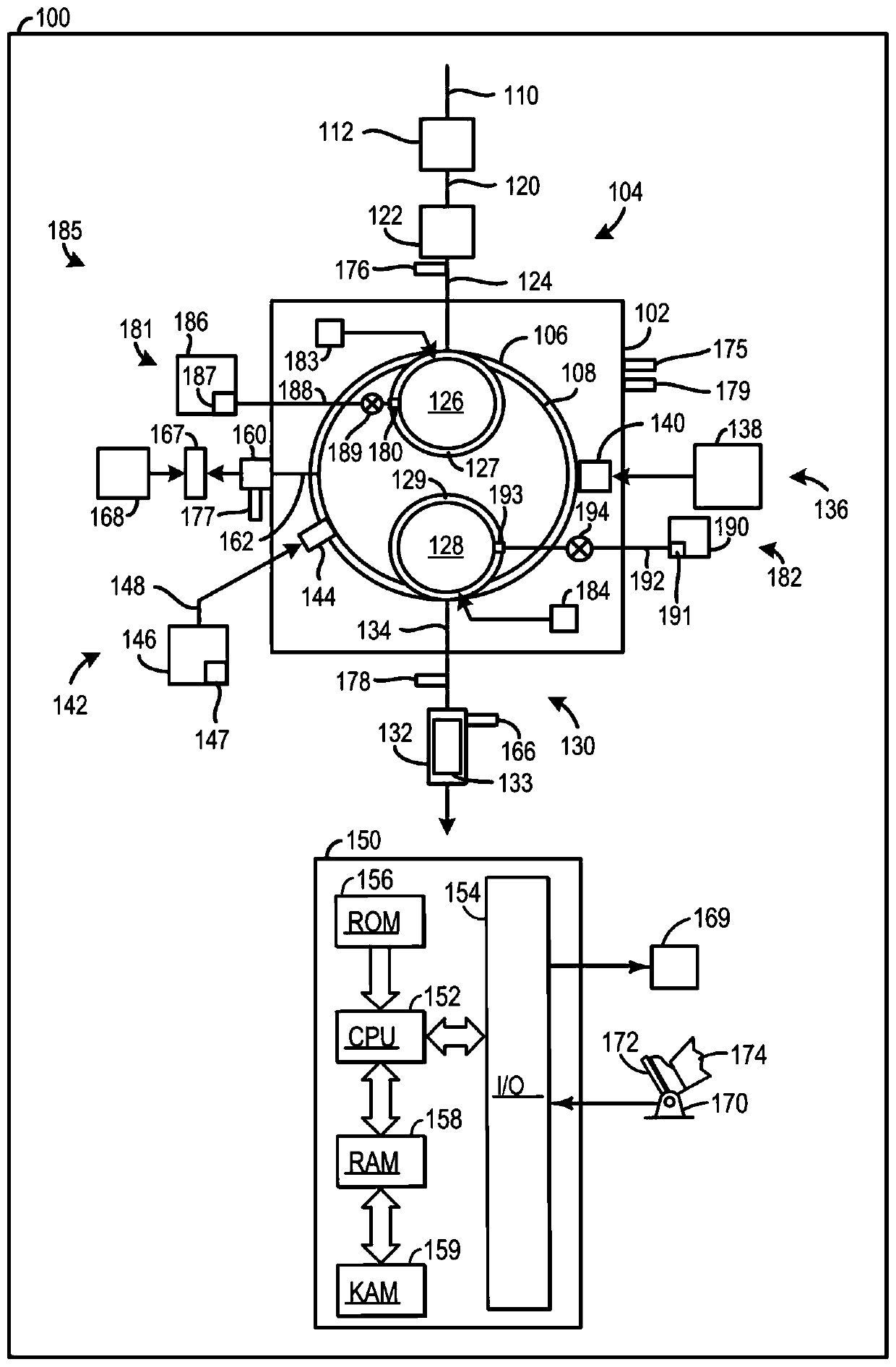

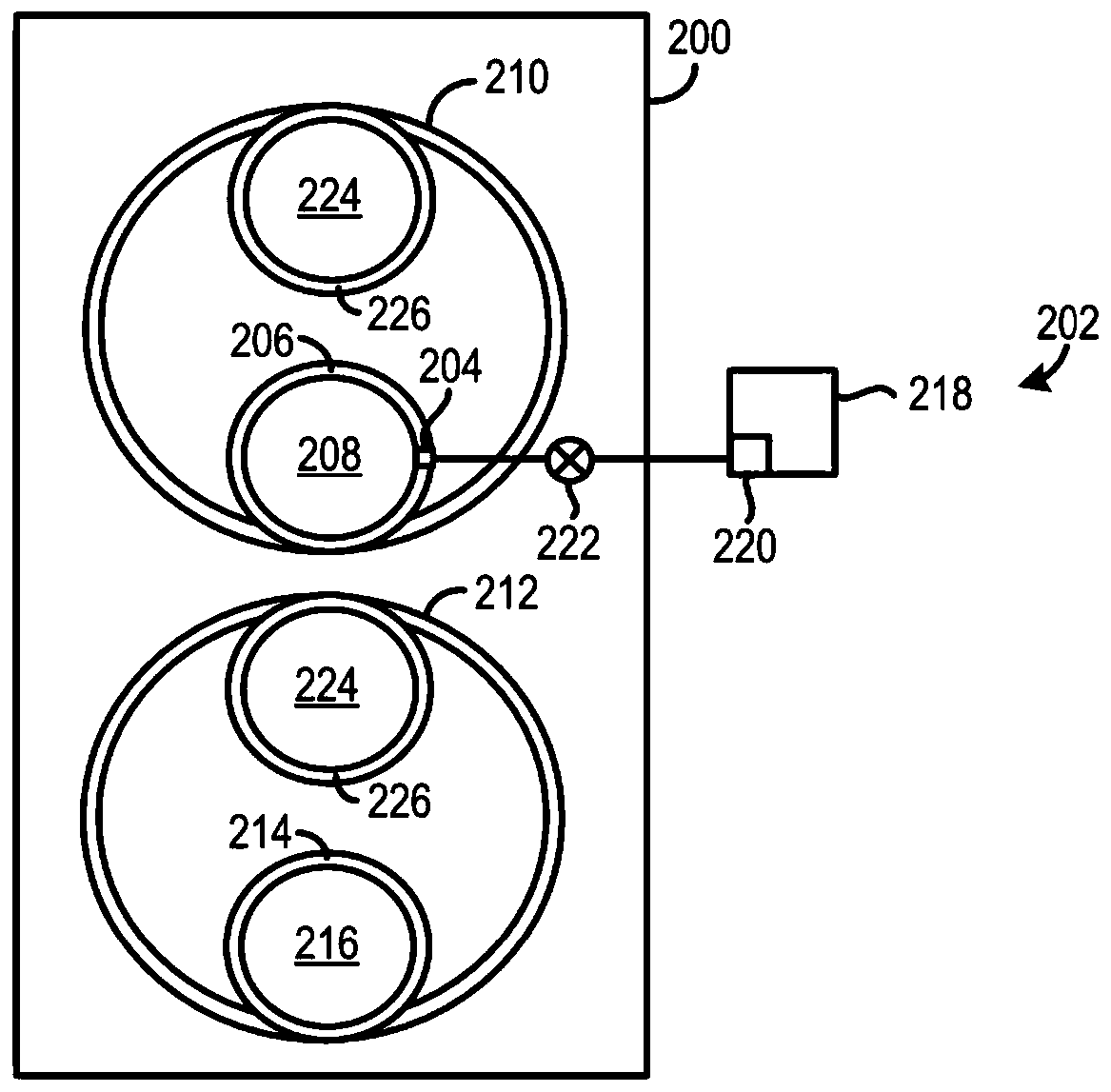

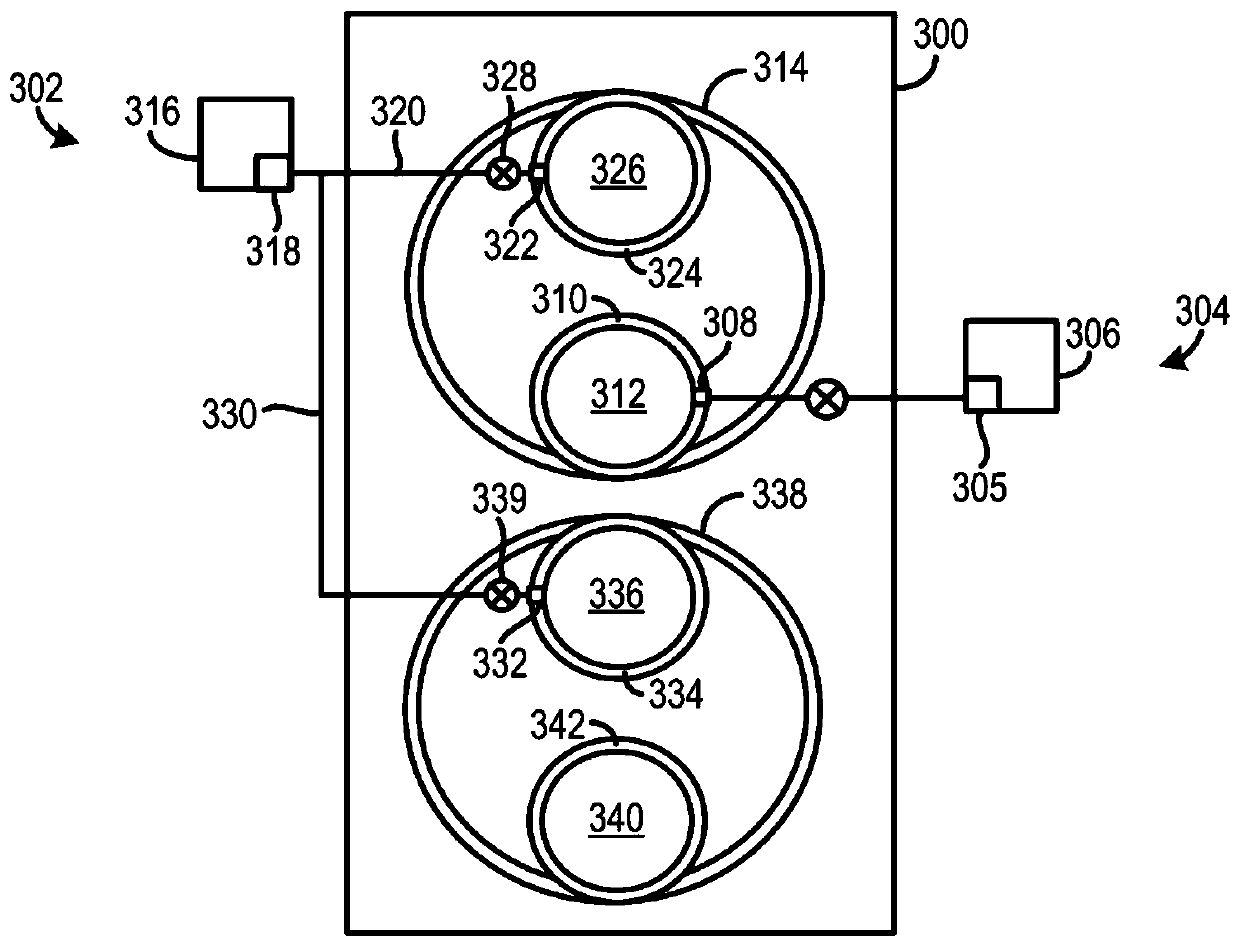

[0019] The following description relates to systems and methods for achieving fluid injection through an orifice in a valve seat. The valve seat fluid delivery assembly is used to direct fluid to the valve seat injection orifice. The fluid delivery assembly may include a fluid reservoir that stores fluid. When the injection orifice is included in the intake valve seat, the fluid may be alcohol, water, petroleum-based fuel, combinations thereof, and the like. In this way, the injection orifice can be operated to improve combustion efficiency, if desired. Conversely, when the injection orifice is included in the exhaust valve seat, the fluid may be exhaust fluid, air, combinations thereof, or the like. In this way, the injection orifice can be operated to reduce emissions, if desired.

[0020] A pump may also be included in the fluid delivery assembly and designed to generate fluid flow from the reservoir to the valve seat injection orifice. The position of the valve head de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com