Mist spray sedimentation purification chamber

A clean room and settling room technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of simple structure, large water consumption, imperfect functions, etc., and achieve the effect of compact structure and uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

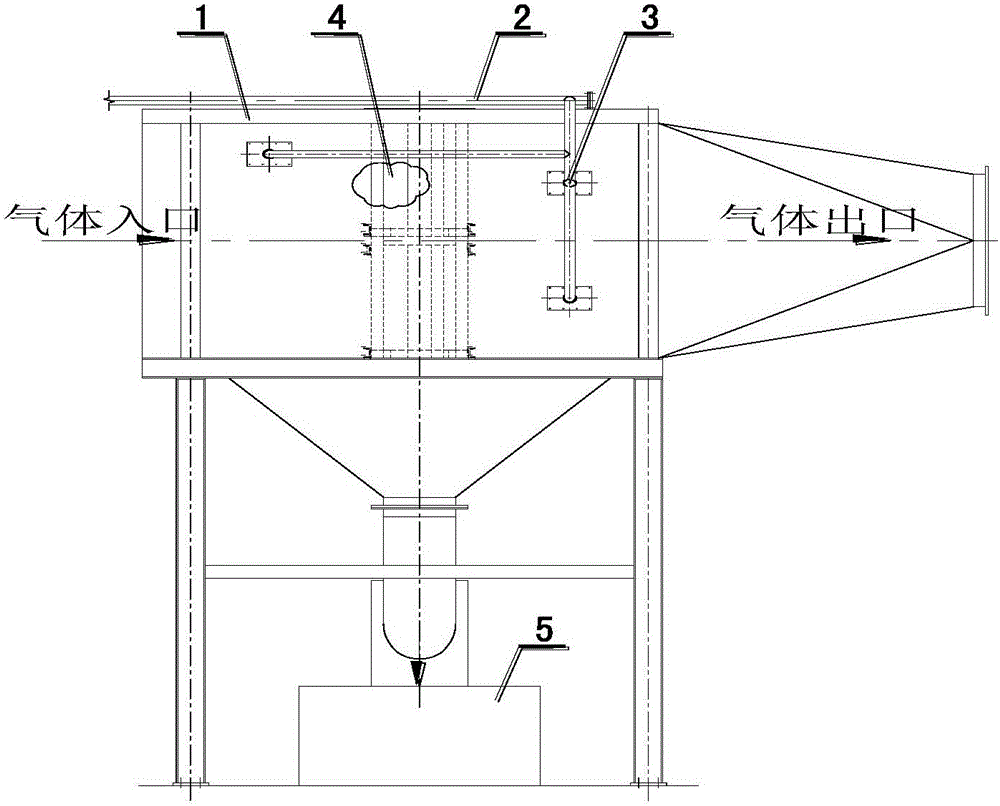

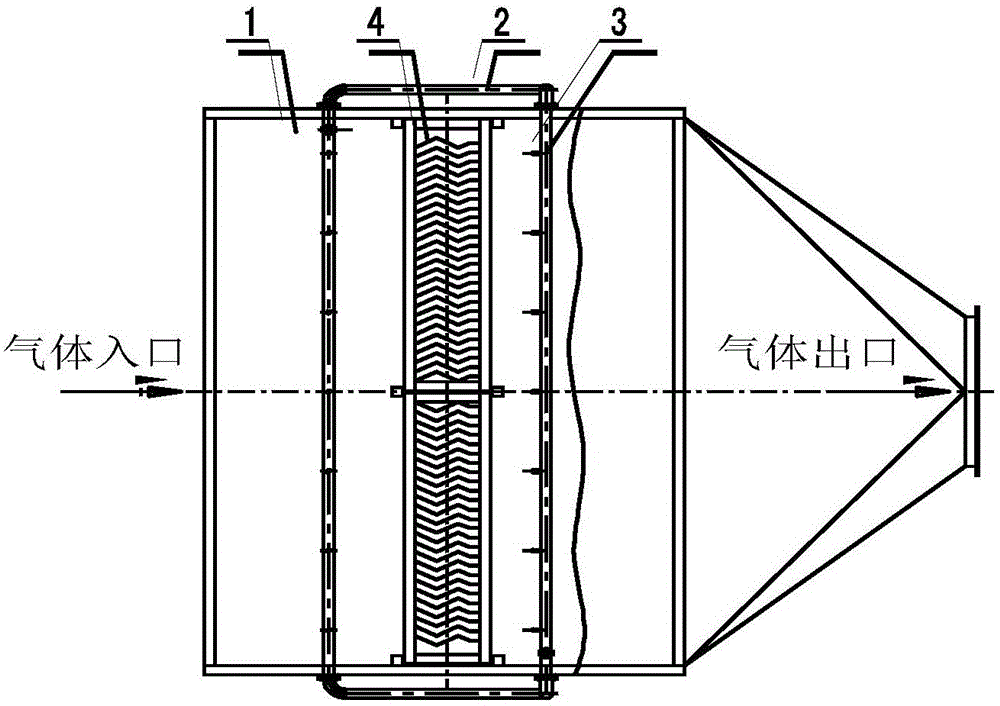

[0023] Such as figure 1 , figure 2 It is a schematic diagram of a spray sedimentation purification room equipment of the present invention, which is mainly composed of a sedimentation chamber 1, a water supply piping system 2, a water spray device 3, a dust separator 4, and a waste liquid settlement tank 5.

[0024] The spray sedimentation purification chamber includes a settling chamber 1, a water supply piping system 2, a water spray device 3, a dust separator 4 and a waste liquid settling tank 5; the settling chamber 1 includes an air inlet, an exhaust port and a liquid discharge port; the water supply pipe The system 2 is installed on the settling chamber 1, the water spray device 3 is connected with the water supply pipe system 2, the water spray device 3 and the dust separator 4 are installed inside the settling chamber 1; the water spray device 3 has several groups, which are respectively installed in the dust separator 4 in different positions, and at least one group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com