A kind of microcapsule and preparation method thereof

A technology of microcapsules and capsule walls, which is applied in the field of protein microcapsules and its preparation, can solve the problems of cumbersome preparation process, microcapsule perforation, breaking, etc., and achieve the effects of increasing application value, good stress resistance, and enhancing insecticidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A) Preparation of core material

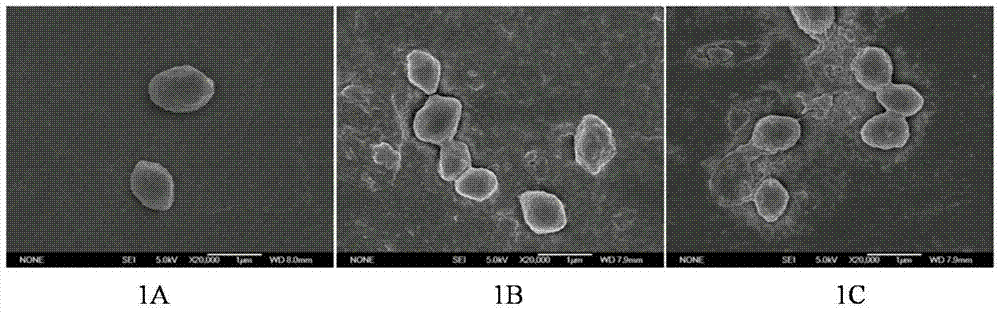

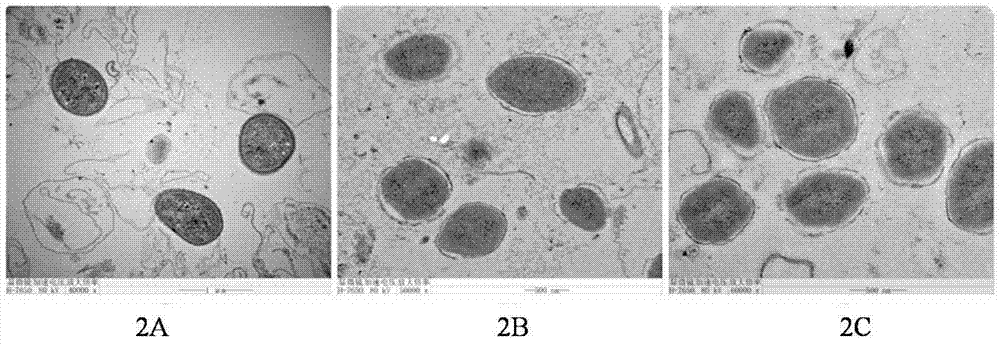

[0036] Cry8Ca2 spherical crystal protein and spore mixture extraction process or refer to Ke Luo, DavidBanks, Michael J. Adang.Toxicity, binding, and permeability analyses of fourBacillus thuringiensis Cry1 delta-endotoxins using brush border membranevesicles of Spodoptera exigua and Spodoptera frugiperda.Appl Environ Microb, 1999, 65: 457–464. It should be noted that this method extracts a mixture of crystal protein and spores. Because the spores can also play an insecticidal effect after germination, and they have strong resistance to stress, and at the same time, it does not affect the protein crystals as the core material to be wrapped by the wall material, so there is no need to remove the spores before preparing the microcapsules with crystal protein. However, in this embodiment, spores are removed and pure protein crystals are used as the core material to be wrapped.

[0037] The separation process of crystal protein and spores or r...

Embodiment 2

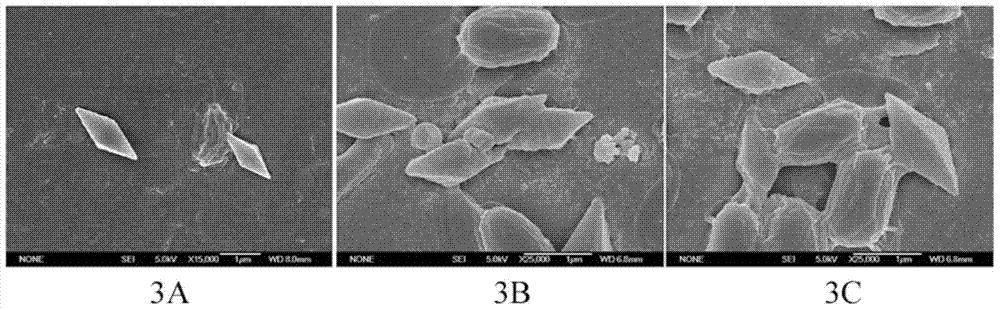

[0049] Preparation of core material: the process of extracting the mixture of Cry1Ac three-dimensional rhombic crystal protein and spores or refer to KeLuo, David Banks, Michael J. Adang. Toxicity, binding, and permeability analyses of four Bacillus thuringiensis Cry1 delta-endotoxins using brush border membranevesicles of Spodoptera exigua and Spodoptera frugiperda. Appl Environ Microb, 1999, 65:457-464.

[0050] 1.0mg / ml Cry1Ac three-dimensional rhombohedral crystal protein and spore mixture: 50mg Cry1Ac crystal protein and spore mixture was dissolved in 50ml of distilled water. The concentration is the concentration of the protein, and the method for determining the concentration is the protein concentration measured after protein electrophoresis using SDS-PAGE.

[0051] Take 10 ml of the 1.0 mg / ml Cry1Ac crystal protein and spore mixture solution prepared above, centrifuge at 6000 rpm for 20 minutes (min), and discard the supernatant. The precipitate was washed with water and ...

Embodiment 3

[0056] Use 95% DD chitosan and sodium alginate as wall materials, and the others are the same as in Example 2.

[0057] In the end, Cry1Ac crystal protein is used as the core material, and the inner-out (chitosan-sodium carboxymethyl cellulose) 5 The sequence of assembled protein microcapsules. The capsule wall of the protein microcapsule is 10 layers. And the prepared protein microcapsules are doped with spores or spore microcapsules wrapped by wall materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com