An automatic riveting machine

A riveting machine and automatic technology, which is applied in the direction of fasteners, buttons, buttons, etc., can solve the problems of large close-contact operation methods, poor riveting effect, and potential safety hazards, so as to achieve good riveting effect, The effect of eliminating hidden dangers and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

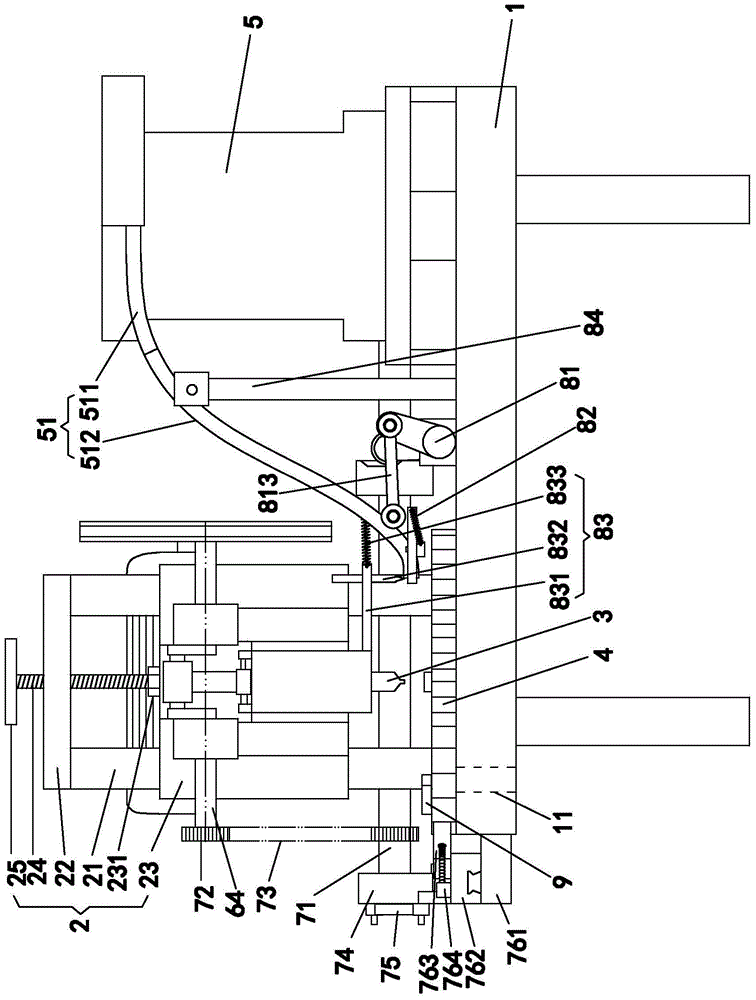

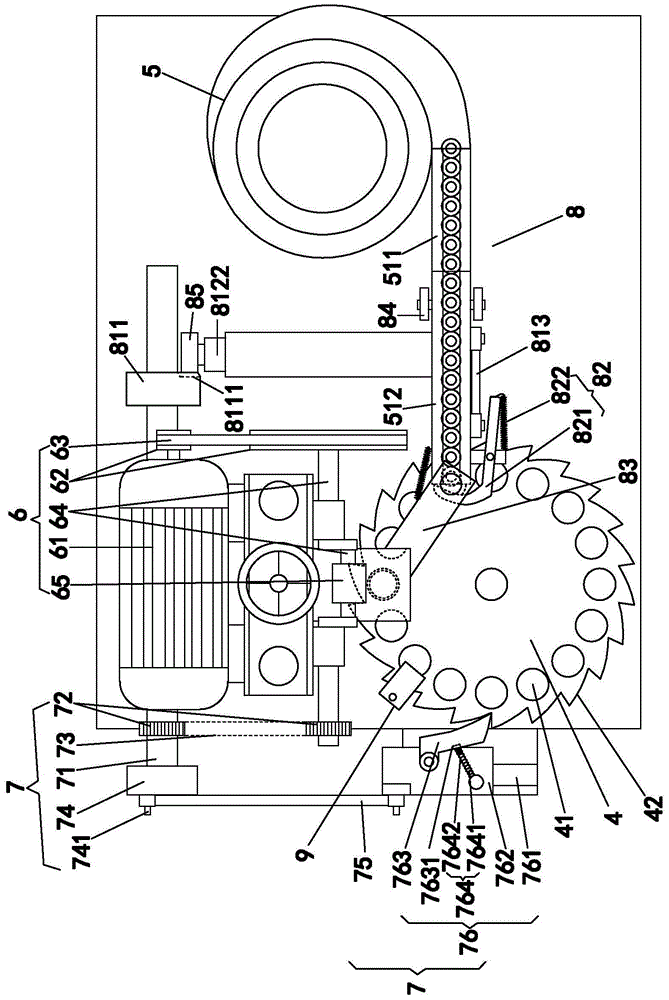

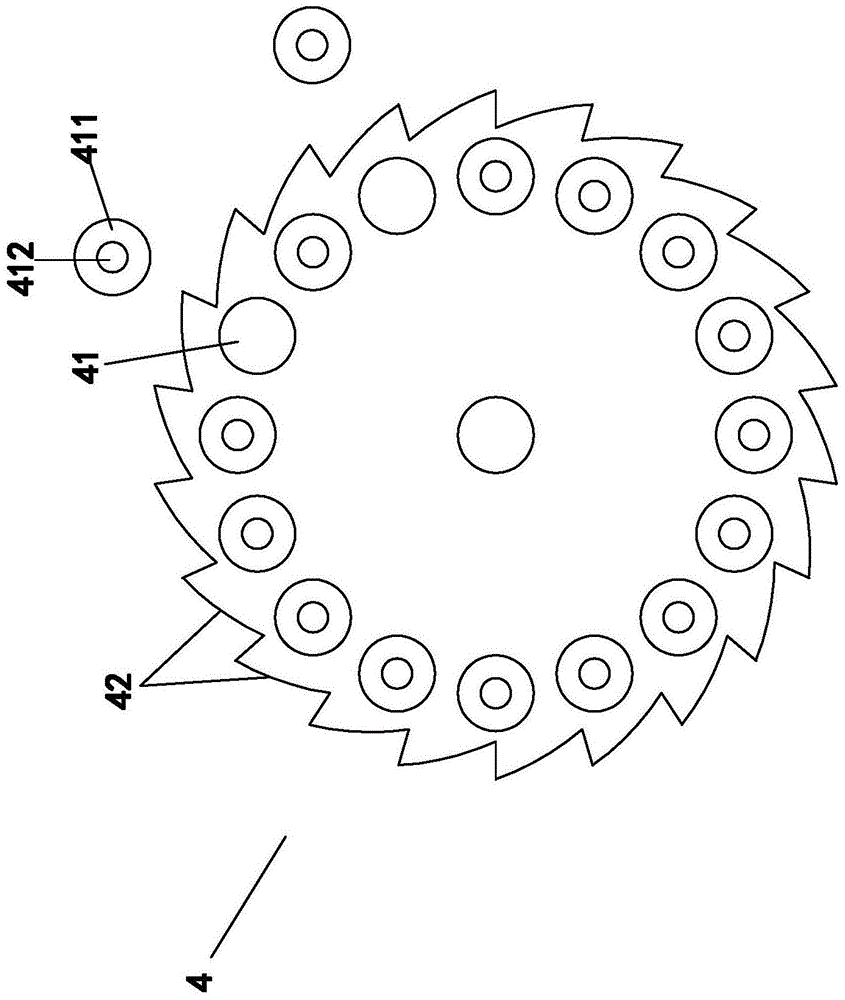

[0044] An automatic riveting machine, such as figure 1 and figure 2 Shown includes a workbench 1, a workframe 2 arranged on the workbench 1, and a stamping cutter head 3 which is arranged on the workbench 2 and can slide up and down relatively. The difference between the present invention and the prior art is that it also includes a The rotating working disk 4 set on the working table 1, the automatic discharge barrel 5 that automatically unloads the material onto the working disk 4, the driving mechanism 6 that drives the stamping cutter head 3 to slide up and down relative to the working frame 2, and the connecting driving mechanism 6 for transmission work The transmission mechanism 7 that the disk 4 rotates.

[0045] The automatic discharge barrel 5 is a well-known technical structure principle, and it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com