A five-station equipment for processing file boxes

A five-station, file box technology, applied in metal processing equipment, metal processing, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

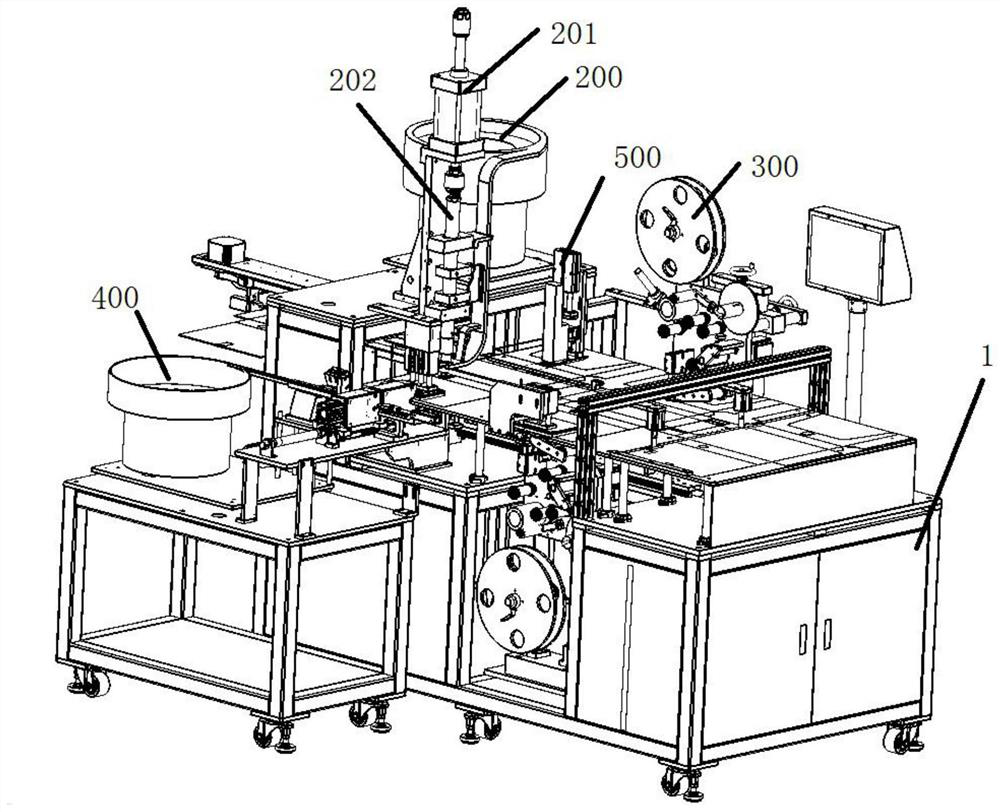

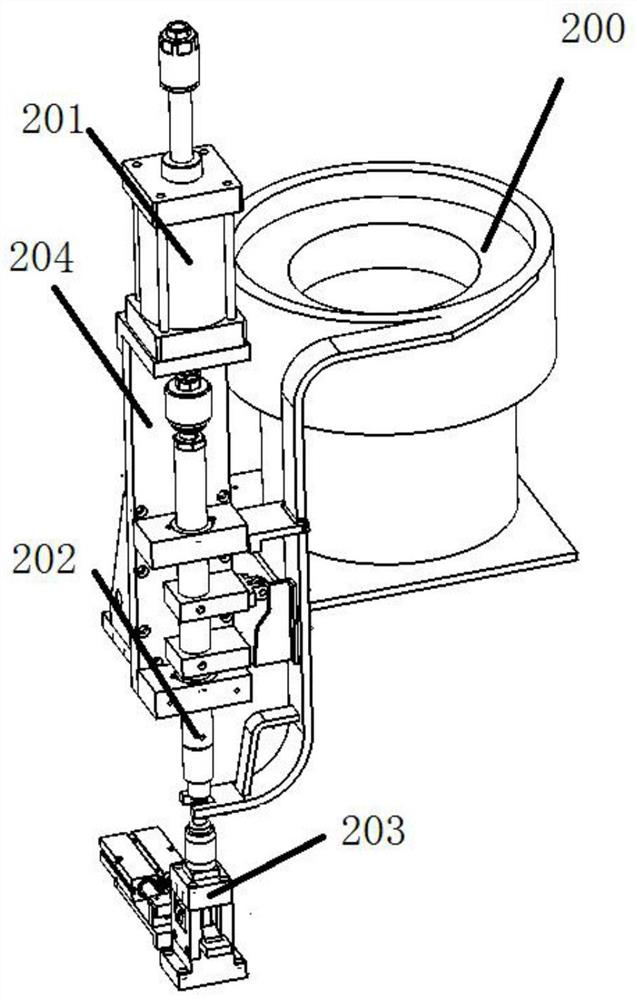

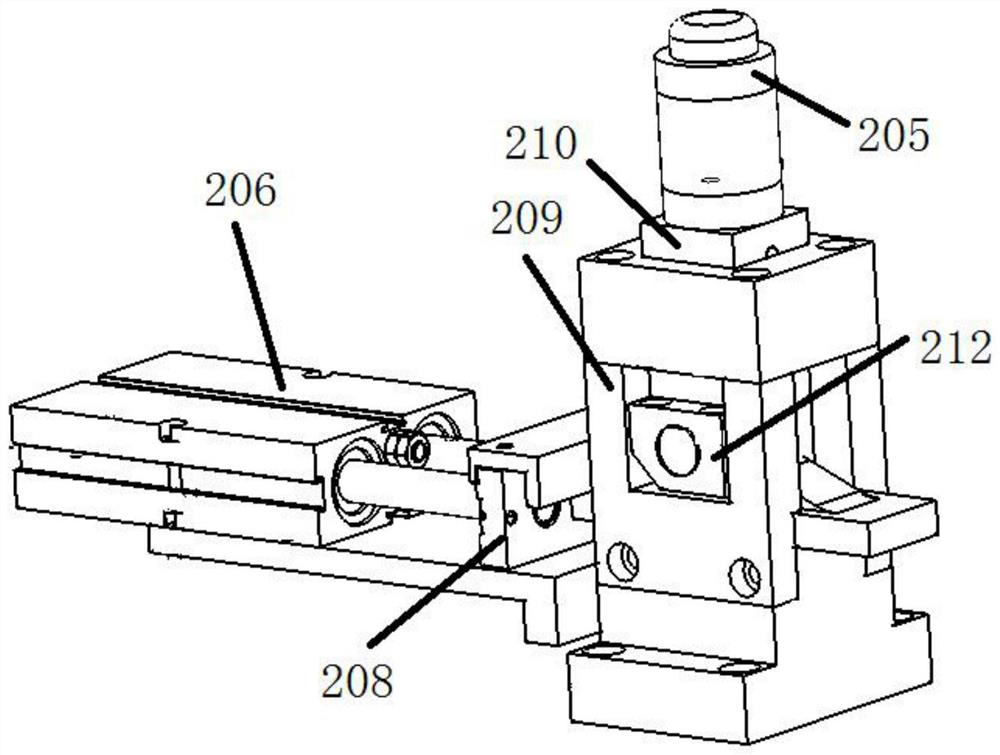

[0051] see figure 1 As shown, the present invention relates to a five-station equipment for processing file boxes, which includes an organic platform 1, and the surface of the machine platform 1 is provided with a pulling module for clamping materials and moving along the axial direction of the machine platform 1, for The labeling module is used to paste the label paper on the material, the saddle stitching module to bind the label attached to the material, the feeding module to provide the LOGO to the material, and the LOGO to be pressed on the surface of the material. The pressing module is a stamping module that stores the ring buckle and presses the ring buckle on the surface of the material.

[0052] Specifically, in the five-station equipment of the embodiment of the present invention, under the action of the pulling module, the material passes through the labeling module and correspondingly enters the saddle stitching module, the pressing module, and the stamping module. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com