Paver advancing, steering and supporting device

A support device and paver technology, which is applied to fluid steering mechanisms, roads, road repairs, etc., can solve the problems of unobstructed 360° rotation, uneven force on steering support devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

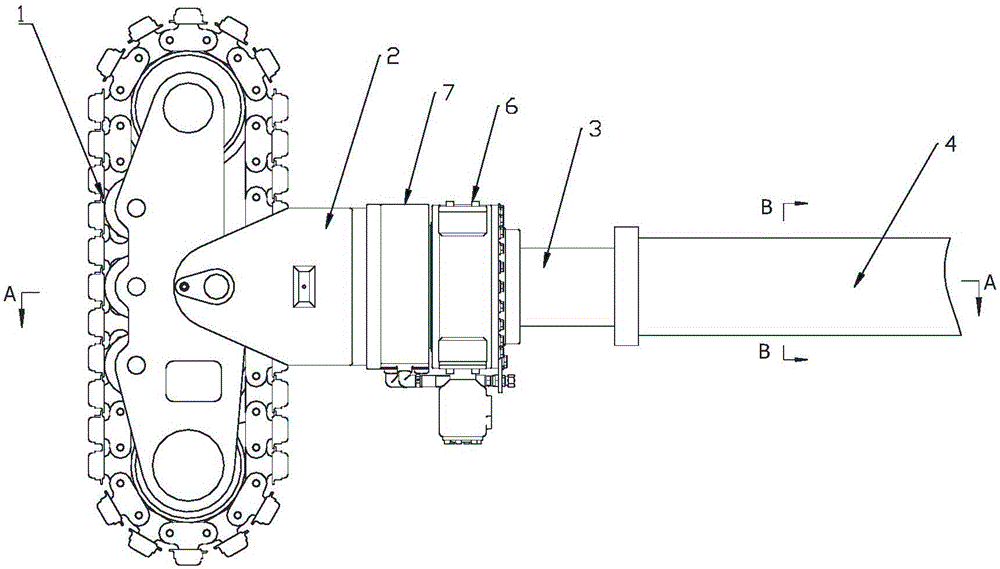

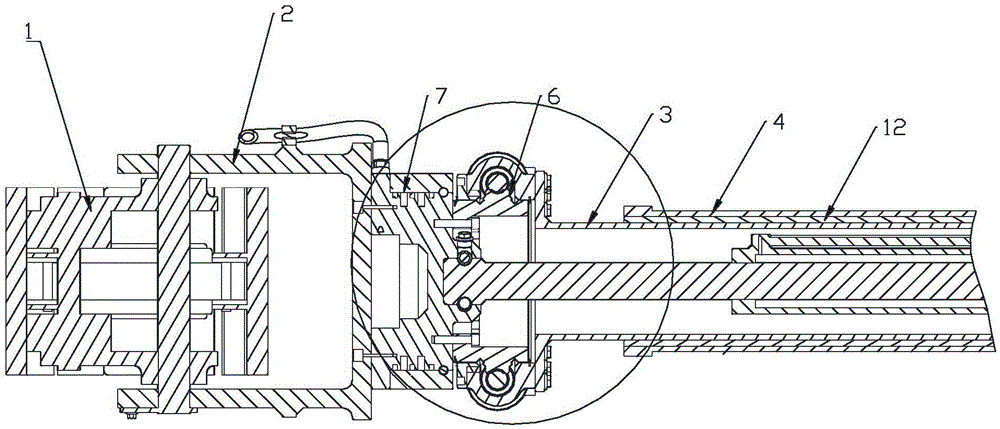

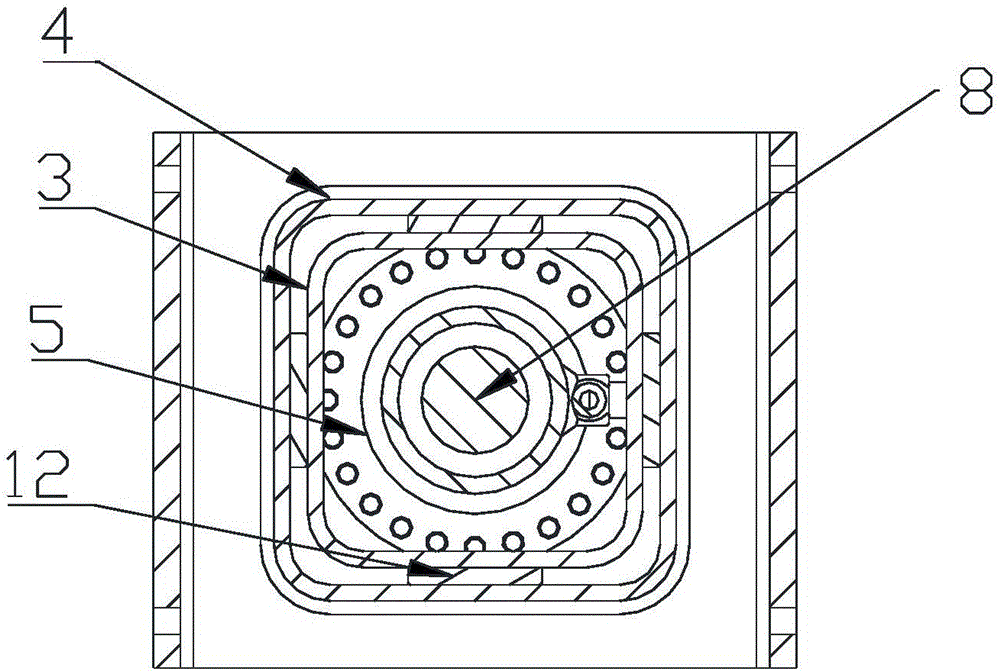

[0024] like Figure 1-Figure 6 As shown in , a paver travel steering support device, which includes a travel device 1, a fixed bracket 2, a lifting column 3, a support body 4, a thrust cylinder 5, a rotary drive device 6 and an oil circuit rotary joint 7, wherein the travel device 1. The traveling device can specifically be a tire or a crawler belt. A fixed bracket 2 is fixed above the traveling device 1. An oil circuit rotary joint 7 is fixed above the fixed bracket 2. A rotary drive device 6 is fixed on the upper end of the oil circuit rotary joint 7. The upper end of the slewing drive device 6 is vertically fixed with a lifting column 3. The lifting column 3 and the support body 4 are hollow square prisms with the same shape inside and outside. The lifting column 3 is covered with a support body 4. A slide bar 12 is provided between the opposite surfaces of the outer walls of the column 3, the top of the inner cavity of the support body 4 is fixedly connected with the top o...

Embodiment 2

[0028] like Figure 7-Figure 9 A paver driving steering support device shown in , the overall structure of this embodiment 2 is the same as that of embodiment 1, the difference is that the lifting column 3 and the support body 4 are hollow cylinders with the same shape, and the lifting column jacket There is a support body 4, and a lifting column positioning device 29 is also provided on the lifting column. The relative chute 13 is fixedly fitted with a positioning ring 14 on the outer wall at the bottom of the lifting column 3, and slides the set lifting positioning disc 15 on the outer wall of the lifting column 3 above the positioning ring 14, and is fixedly installed on the inner wall of the lifting positioning disc 15. There are two sliders 16, the sliders 16 slide up and down and are clamped on the chute 13, a support body 4 is fixed above the lifting positioning plate 15, and a reciprocating motion bearing 17 is arranged between the support body 4 and the lifting column, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com