Package box physical structure capable of reducing object breakage

A technology of physical structure and packaging box, which is applied in the direction of transportation and packaging, containers and containers to prevent mechanical damage, etc. It can solve the problems of instrument wear, uneven instrument placement, difficulty in instrument placement and removal, and achieve the effect of slowing up and down vibrations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

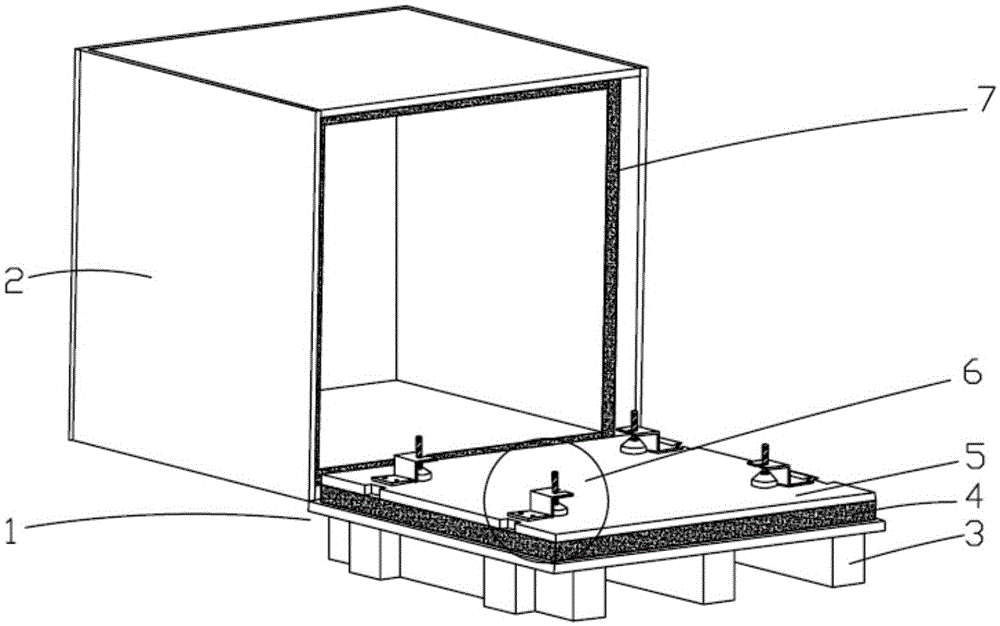

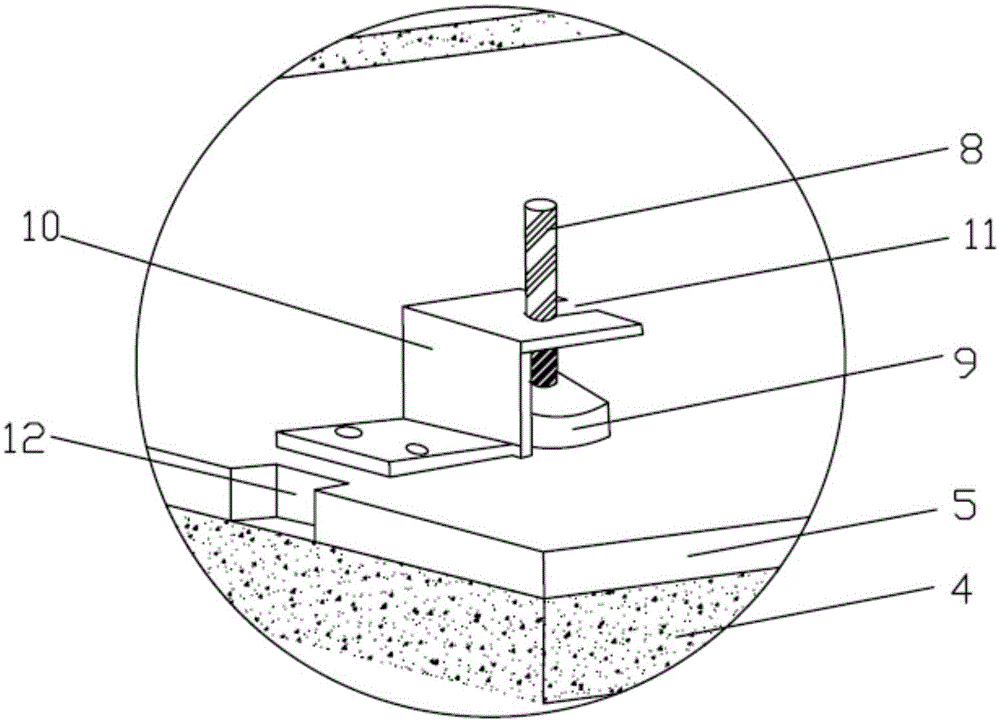

[0017] figure 1 with figure 2 It is a schematic diagram of the present invention.

[0018] The reference signs are: base 1, box cover 2, base 3, buffer bottom layer 4, buffer plate 5, load-bearing component 6, buffer layer 7, load-bearing column 8, load-bearing shoe foot 9, fixing member 10, load-bearing column gap 11. Loading and unloading gap 12.

[0019] The present invention will be described in detail and concretely below through specific embodiments, so as to better understand the present invention, but the following embodiments do not limit the scope of the present invention.

[0020] Taking the transportation of a digital pathological slice scanner as an example, the physical structure of a packaging box that can reduce object damage includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com