Belt deicing device

A belt and de-icing wheel technology, applied in cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of belt conveyor hazards, damage to cleaner scrapers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0034] like figure 1 As shown, a belt deicing device includes a box body 6, a belt hole 63 is opened on each side of the box body 6, and the two belt holes 63 allow a belt to pass through the box body 6 horizontally. The body 6 is provided with an ice breaking wheel 1, a first elastic pressing roller 2, a deicing wheel 3, a second elastic pressing roller 5 and an ice slag cleaner 4 in sequence along the incoming direction of the belt. Two elastic pressing rollers 5 are located at the same height and are in contact with the upper surface of the belt. The cleaner 4 is located at the same height, and the deicing wheel 3 is higher than the ice breaker 1 and the ice slag cleaner 4 .

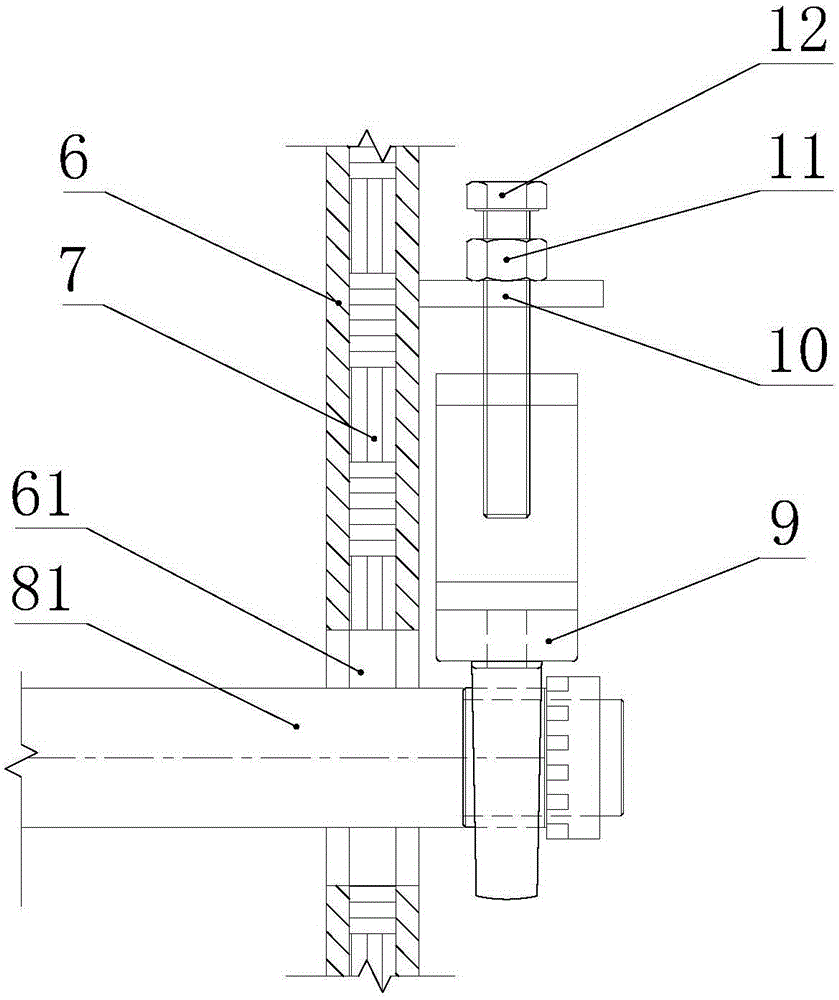

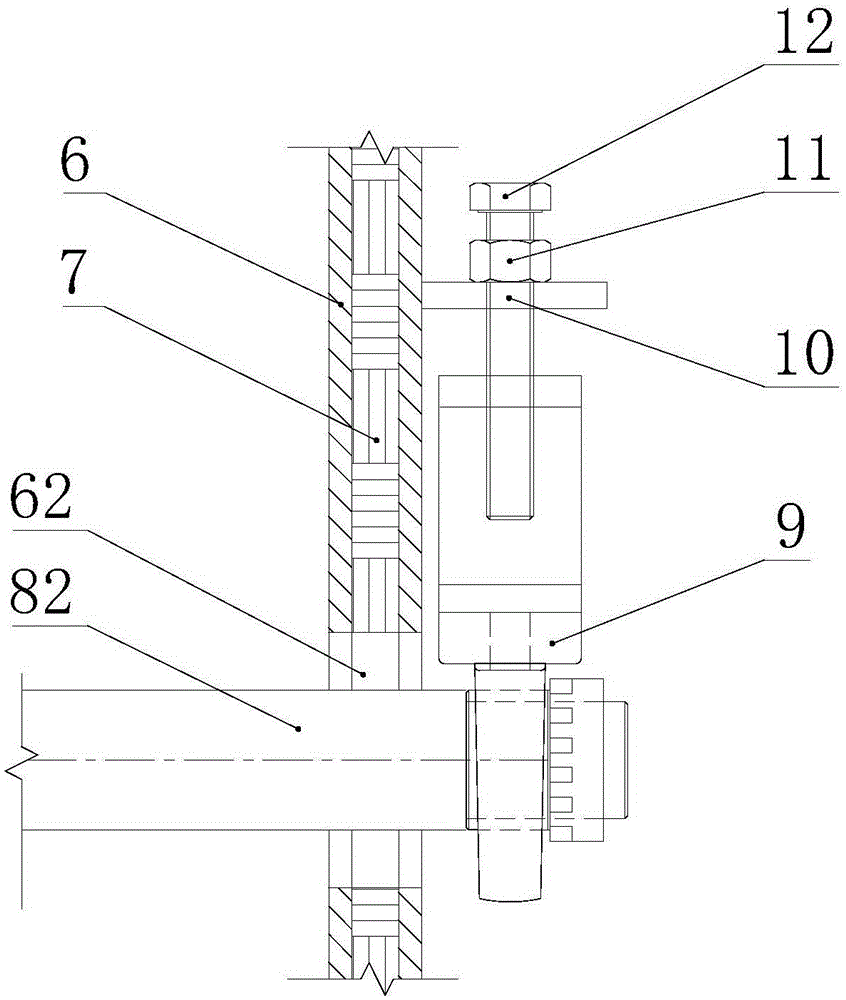

[0035] Figure 5 It is a schematic diagram of the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com