Sinker cap

A technology of smock hood and smock hood, applied in the field of smock hood, can solve the problems of uncontrollable tightness of socks, unstable structure, easy damage, etc., and achieve the effect of stable structure, long service life and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be clearly and completely described below through specific embodiments in conjunction with the accompanying drawings.

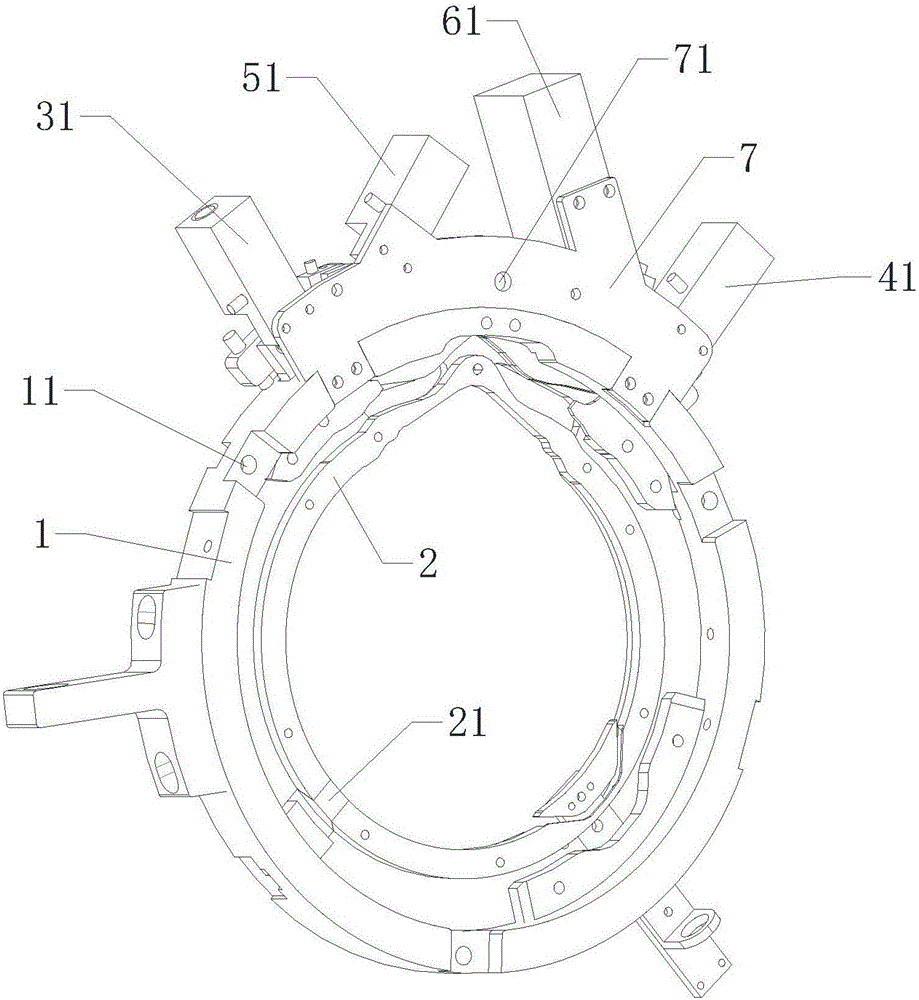

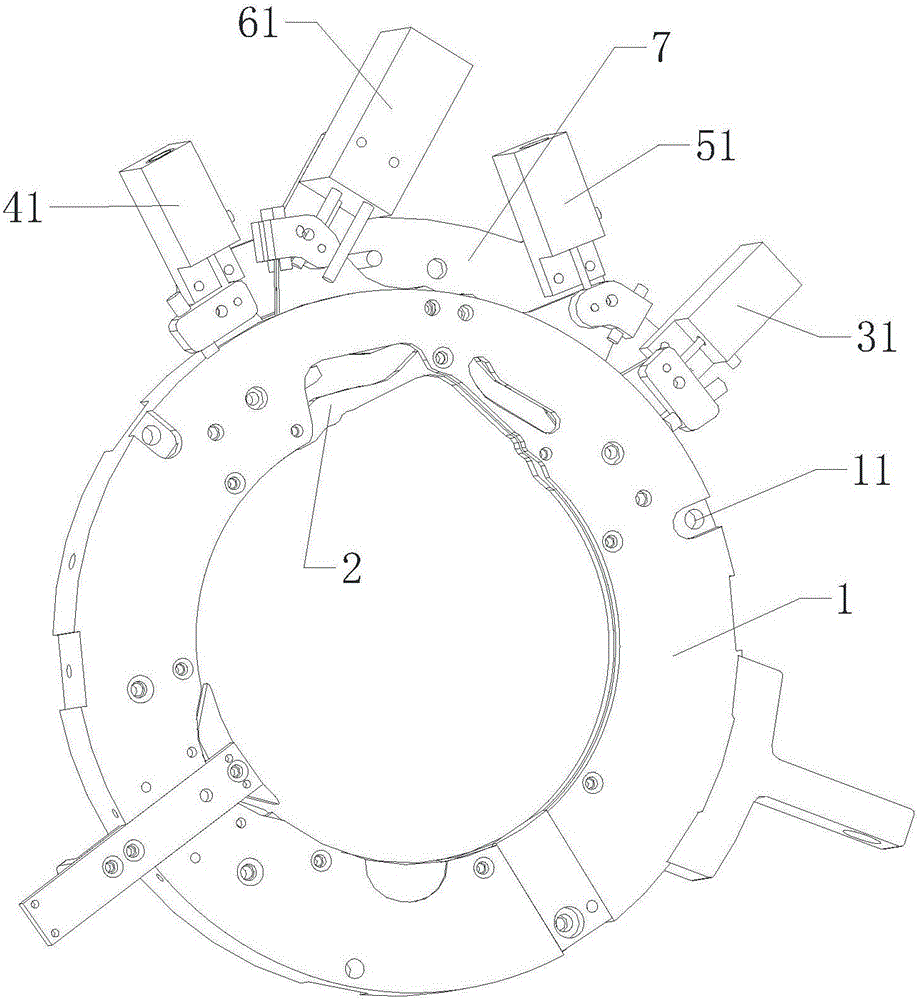

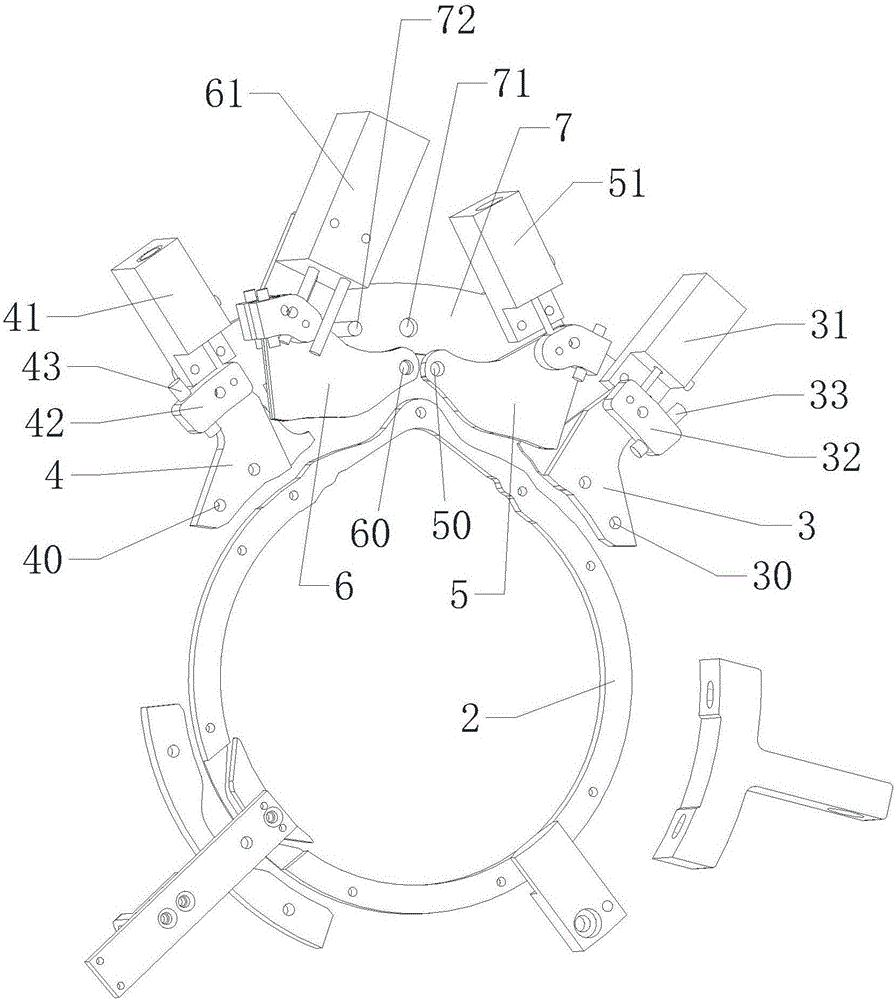

[0022] see Figure 1-5 As shown, the present invention provides a kind of Sheng Ke cover, comprises Sheng Ke cover body 1, middle eyebrow 2, left eyebrow 3, right eyebrow 4, left raising knife 5 and right raising knife 6, described middle eyebrow 2, left eyebrow 3 , the right eyebrow 4, the left raising knife 5 and the right raising knife 6 are all installed on the Shengke cover body 1, and the middle eyebrow 2 is an integral ring structure. The middle eyebrow 2 of the formula has no interface, the structure is more stable, not easy to be damaged, and the service life is long. The middle eyebrow 2 is provided with a notch 21, which is convenient for replacing raw grams. The left and right eyebrows 3,4 are provided with fulcrum holes 30,40, and pin shafts (not shown) are installed at the fulcrum ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com