Estimation method for sequence of voids in mineral aggregate of asphalt mixture

A technology of asphalt mixture and clearance ratio, applied in the field of asphalt pavement materials, can solve the problems of incorrect design results, inaccurate empirical formulas, and inability to guarantee results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

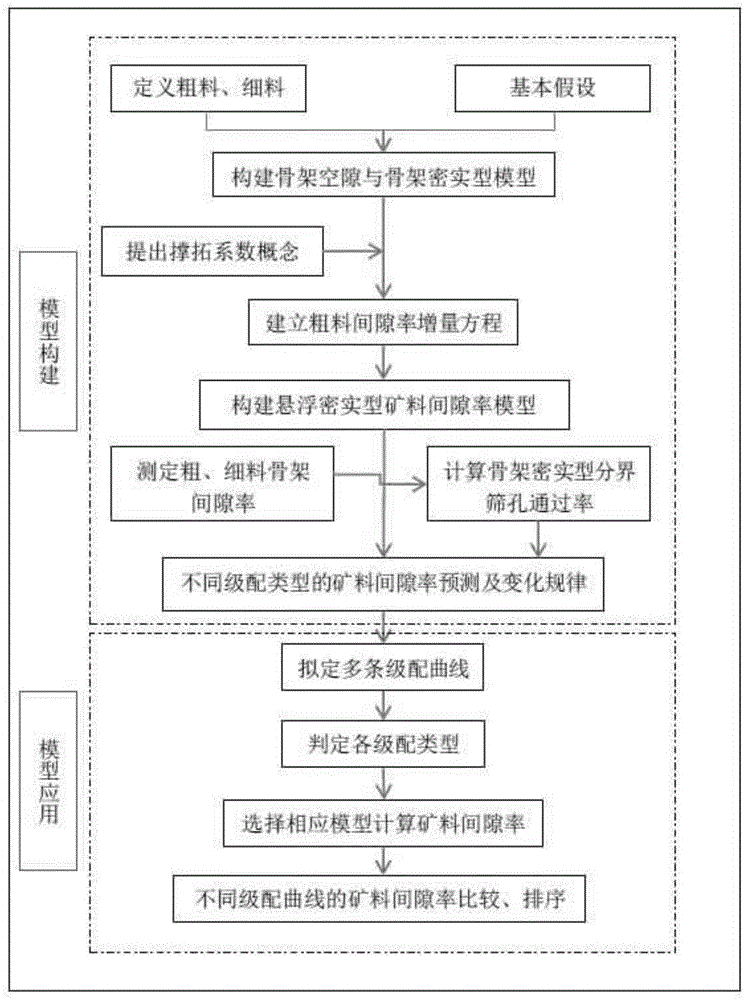

[0044] The model construction process of the present invention, such as figure 1 As shown, the specific steps are as follows:

[0045]Step 1: Basic assumption 1) There is an appropriate boundary particle size between coarse and fine materials. Coarse aggregates larger than the boundary particle size are collectively called coarse aggregates, and fine aggregates and fillers smaller than the boundary particle size are collectively called fine materials. 2) There are two stockpiles of coarse material and fine material. Coarse material is mixed from various grades of coarse aggregate according to a certain law (such as pursuing S-shaped grading curve or maximum density). Fine material It is made by mixing fine aggregate and filler according to similar laws or the mass ratio determined by engineering experience; there is no or very little fine material in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com