Pile foundation length testing method based on thermal response

A detection method and thermal response technology, which are applied in the testing of infrastructure, infrastructure engineering, construction, etc., can solve the problems of error in test results, high economic cost, inaccuracy of test results, etc., and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

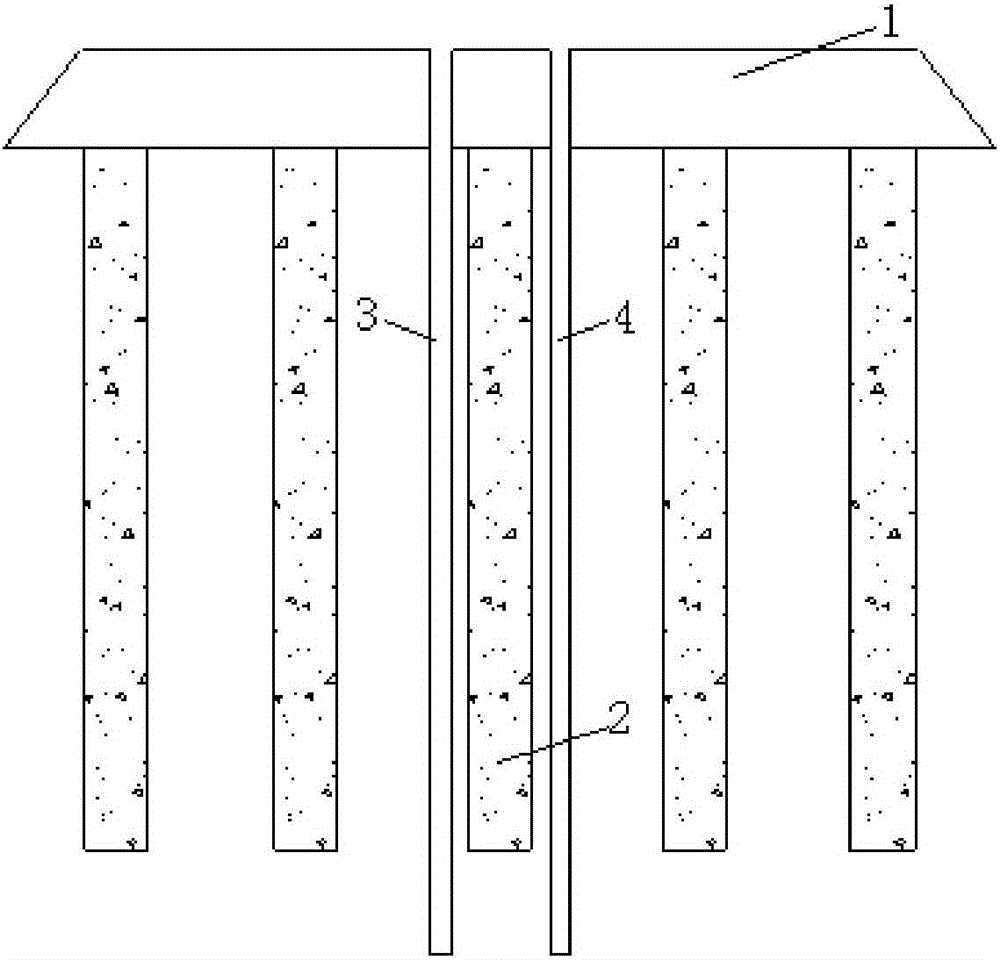

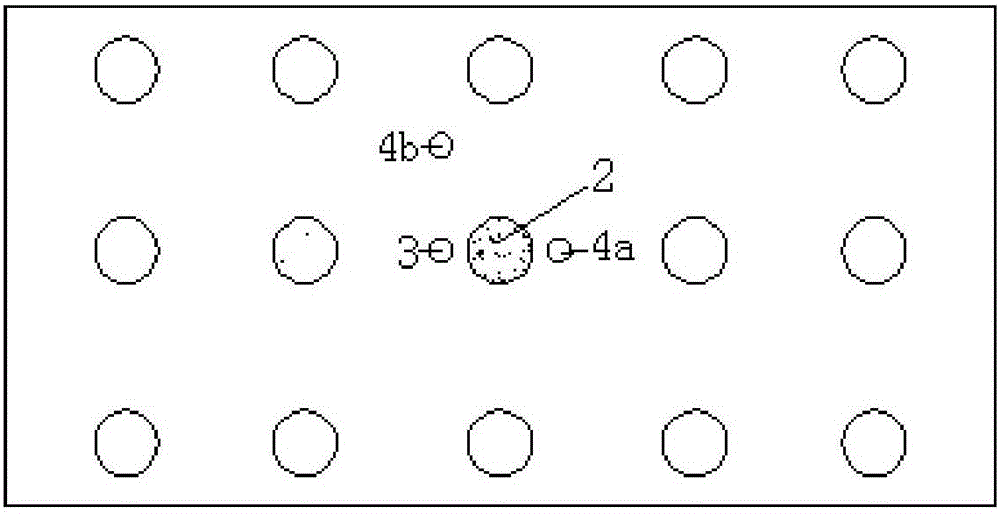

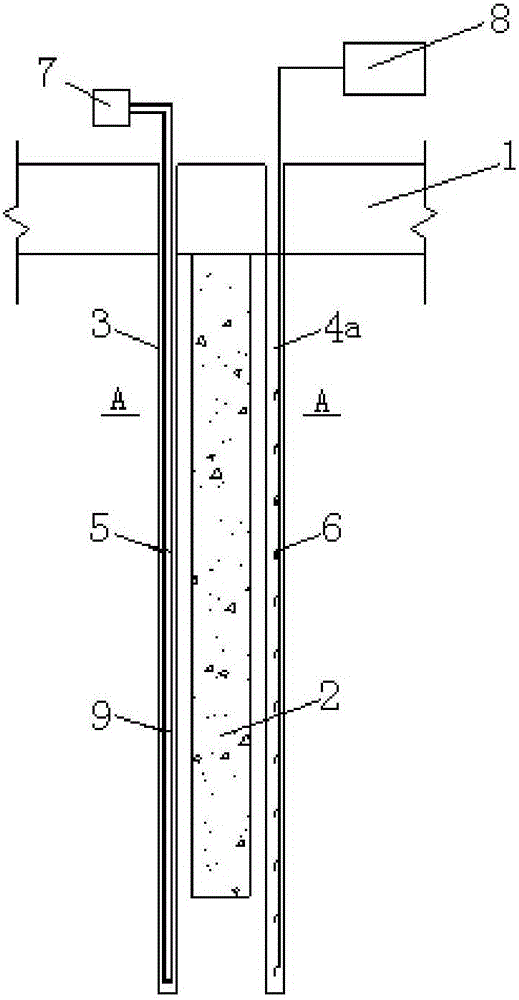

[0027] like Figure 1a to Figure 2b As shown, a pile length detection method based on thermal response, in Fig. 1 and Fig. 2, holes are drilled from the superstructure 1 to the test depth, respectively heat source hole 3, first temperature measurement hole 4a, second temperature measurement hole In the hole 4b, the heat transfer tube 5 is tied to the steel bar 9 and placed in the heat source hole 3 and connected to the upper water collector and the pump 7. The temperature measuring probe 6 is placed in the temperature measuring hole 4 equidistantly along the pile depth and connected to the upper information collection system. connected. Utilize the heat transfer pipe 5 to transfer heat to the two temperature measuring holes 4; due to the difference in the thermophysical properties of the pile body material and the underground soil, the temperature at the same depth of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com