Prefabricated wall preformed hole self-sealing waterproof jacket and implementation method

A reserved hole and assembled technology, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of poor expansion effect, hidden danger of leakage, and unfavorable pipeline expansion, so as to facilitate later expansion, save maintenance costs, and improve The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

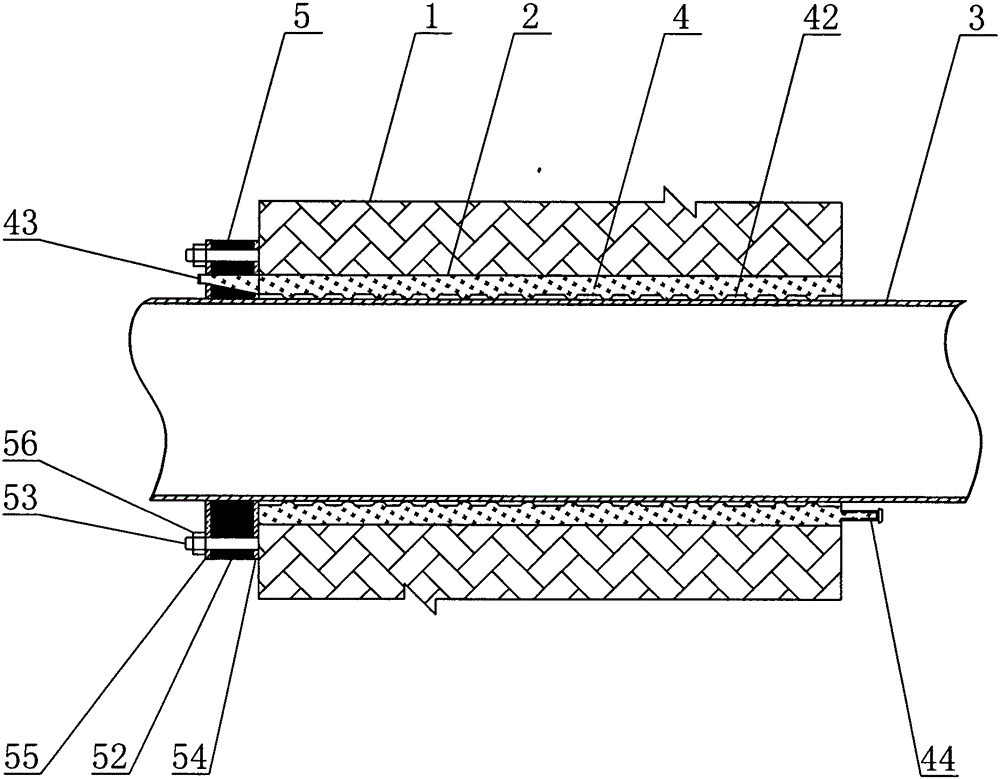

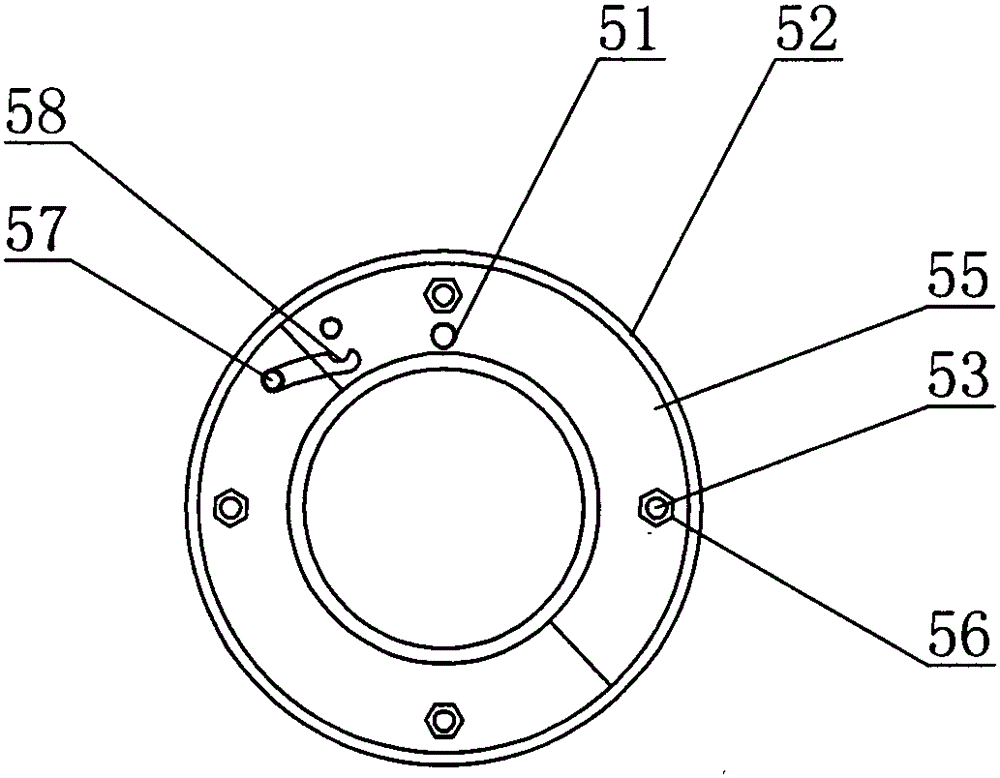

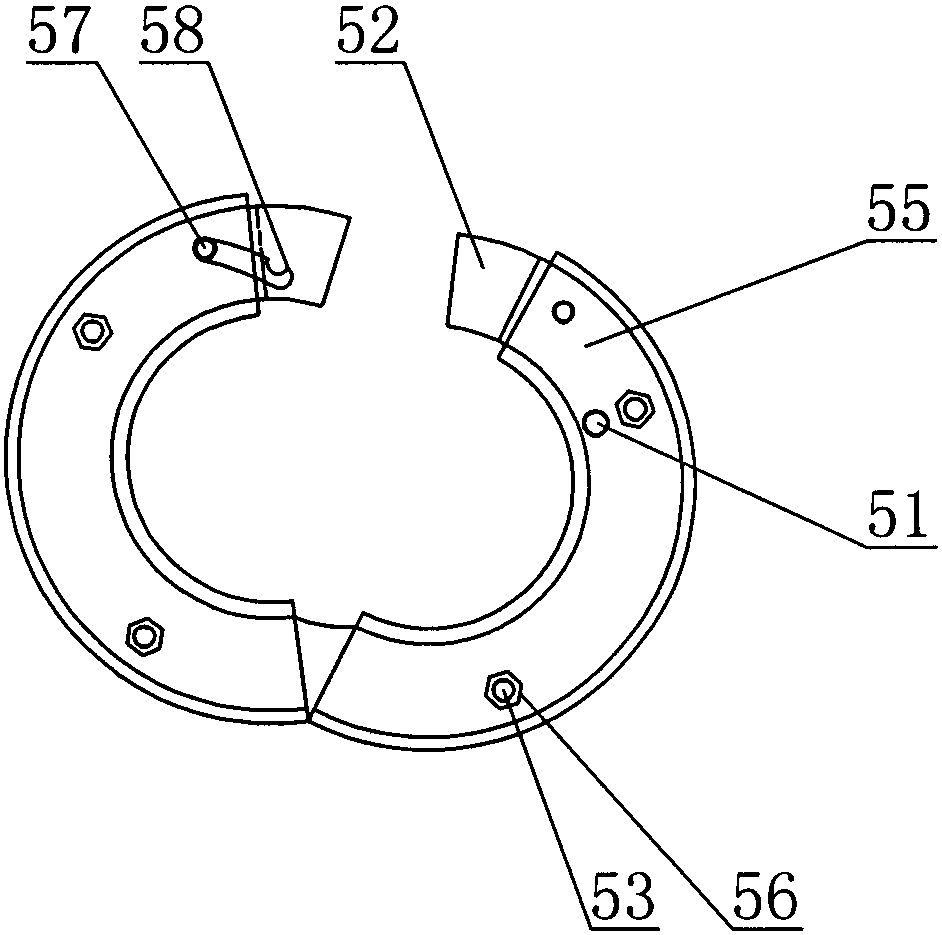

[0056] Embodiment 1: The present invention is a prefabricated wall self-sealing waterproof cover with reserved holes, including a wall, a reserved hole is set on the wall, a pipe is arranged in the reserved hole, and a flexible pipe is arranged on the pipe. Liquid-filled self-sealing capsule, the liquid-filled self-sealing capsule is flat and covers the outer wall of the pipe. The liquid-filled self-sealing capsule is filled with antifreeze liquid and then expands to fill the gap between the inner wall of the reserved hole and the pipe, which can seal the reserved hole. The gap between the inner wall and the pipe is effectively sealed, which can achieve the purpose of waterproof and moisture-proof. The liquid-filled self-sealing capsule is provided with a long strip of Velcro, which can fix the liquid-filled self-sealing capsule. Protrusions are provided on the side of the liquid-filled self-sealing capsule close to the pipeline, and the protrusions are a plurality of strip-sh...

Embodiment 2

[0067]Embodiment 2: The present invention is a prefabricated wall self-sealing waterproof cover with reserved holes, including a wall, a reserved hole is arranged on the wall, a pipe is arranged in the reserved hole, and a flexible pipe is arranged on the pipe. Liquid-filled self-sealing capsule, the liquid-filled self-sealing capsule is flat and covers the outer wall of the pipe. The liquid-filled self-sealing capsule is filled with antifreeze liquid and then expands to fill the gap between the inner wall of the reserved hole and the pipe, which can seal the reserved hole. The gap between the inner wall and the pipe is effectively sealed, which can achieve the purpose of waterproof and moisture-proof. The material of the liquid-filled self-sealing capsule is rubber, which has the characteristics of good elasticity and acid and alkali resistance, which can make the use of the present invention not be affected by the acid and alkali environment, and has the characteristics of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com