Early-dismantling levelling jacking for concrete structure formwork

A technology of concrete structure and flat roof, which is applied to formwork/formwork/work frame, building structure, preparation of building components on site, etc. Concrete surface unevenness and other problems, to ensure the smoothness and visual quality of the concrete surface, reasonable force, and eliminate the deviation of the installation plane position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

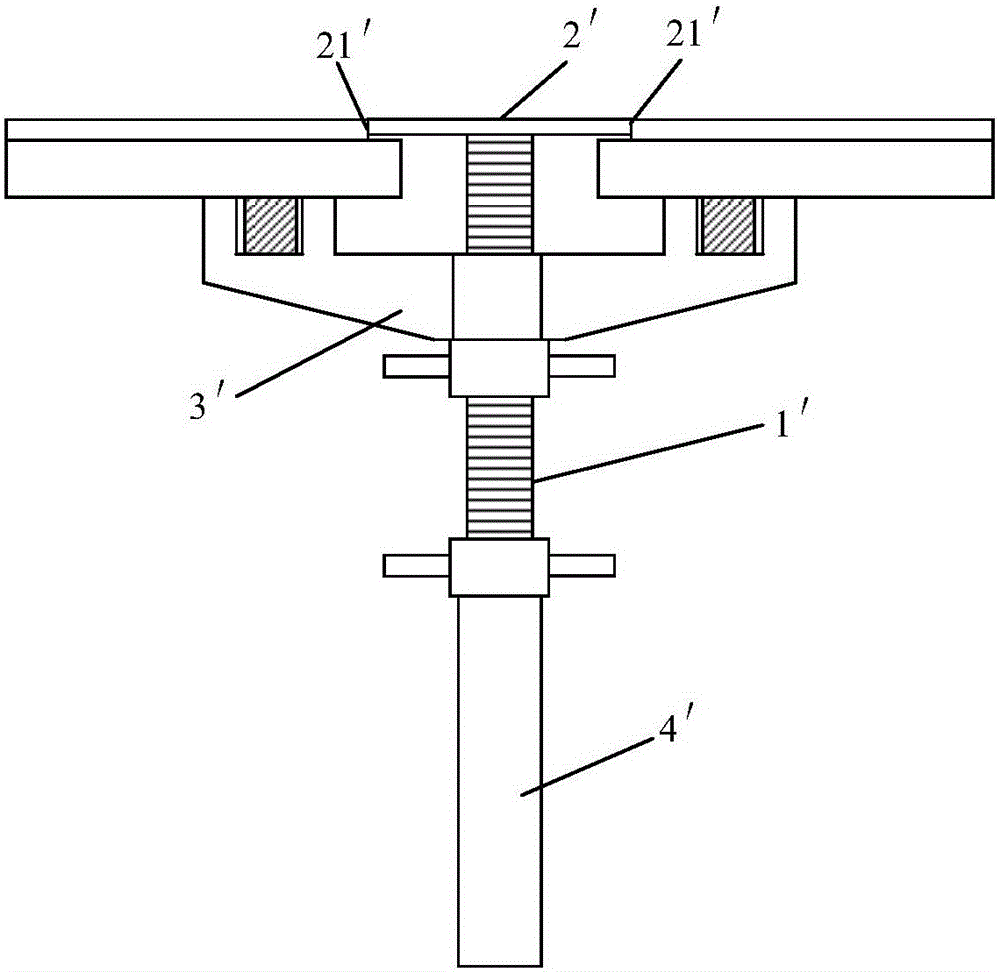

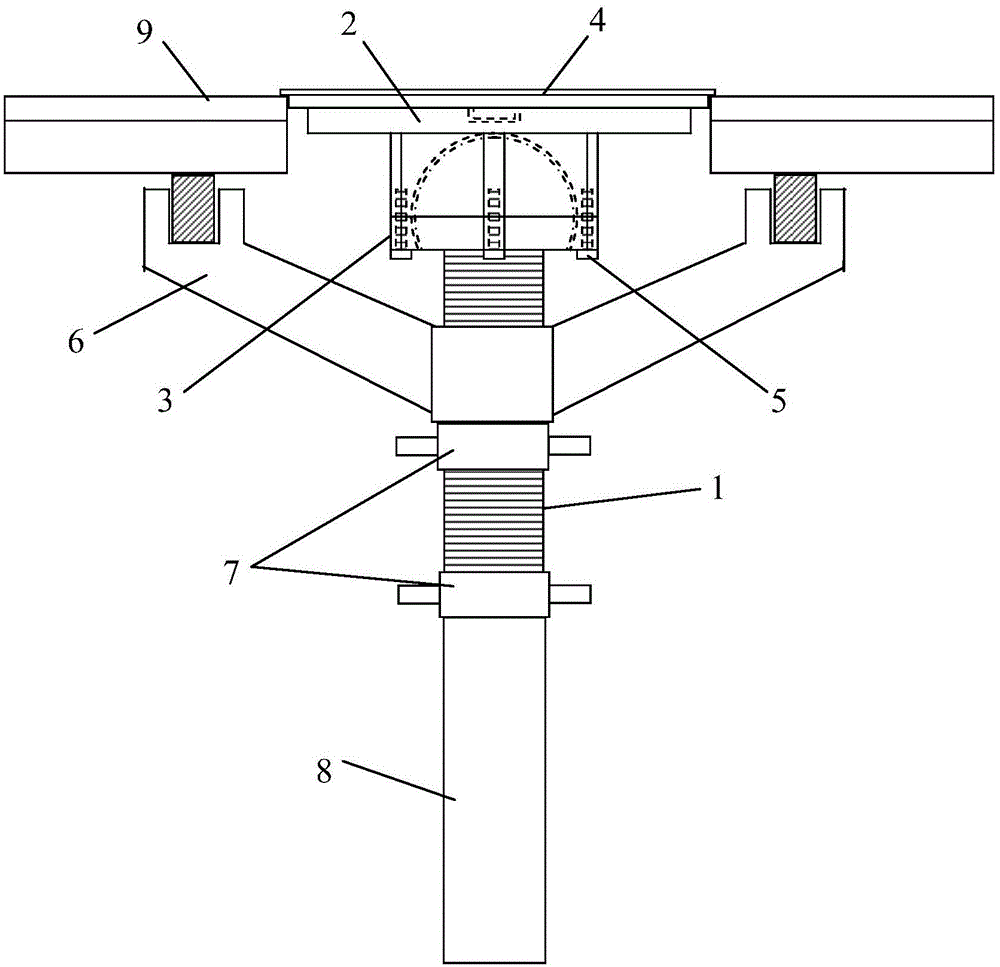

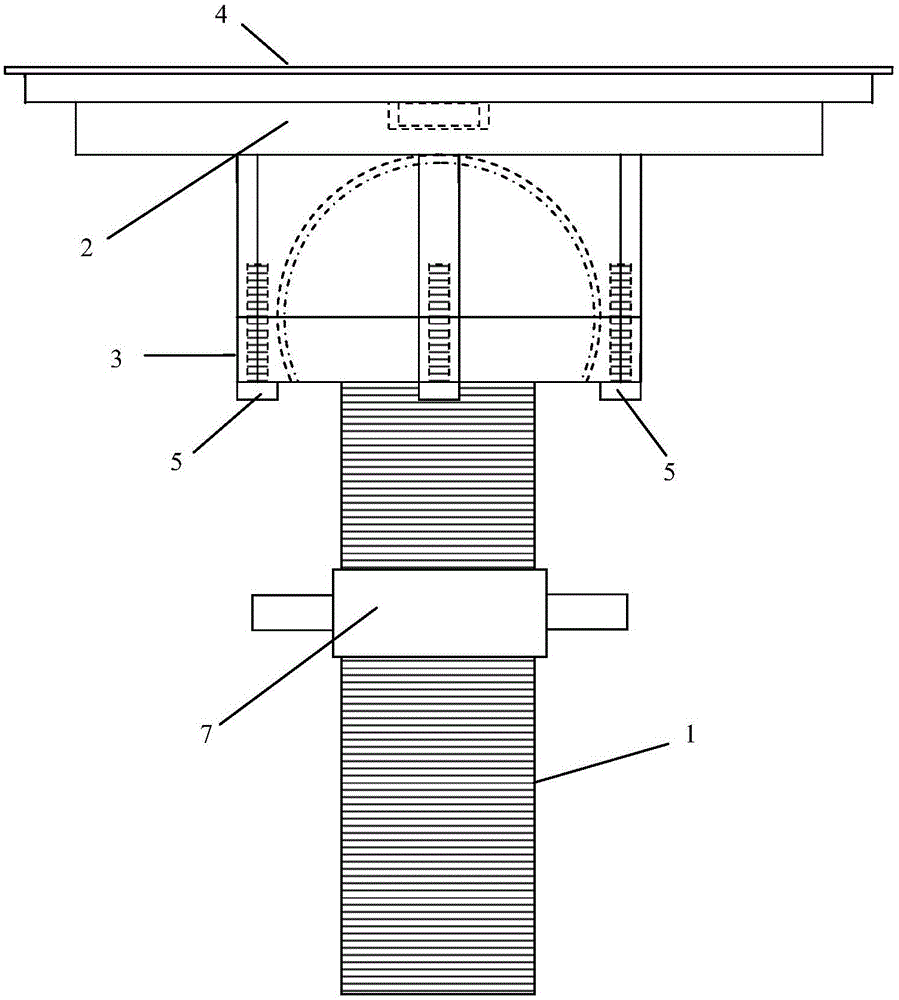

[0022] Such as Figure 2 to Figure 12 As shown, the present invention relates to a concrete structure formwork early dismantling adjustable flat top bracket, the early dismantling adjustable flat top bracket is used in conjunction with the supporting steel pipe of the formwork, and the early dismantling adjustable flat top bracket includes a screw rod 1 , a support 2, a ball ring 3, a movable plate 4, at least three bolts 5, and an early dismantling support 6; wherein, the early dismantling adjustable flat support also includes two adjustment nuts 7, and the support Holder 2 also includes a supporting plate 21 and a short cylinder 22, inside the short cylinder 22 is a hemispherical bowl surface 223, one end of the short cylinder 22 is fixedly connected with the bottom surface of the supporting plate 21, and the peripheral sides of the short cylinder 22 are at least evenly distributed Three first protrusions 221, each first protrusion 221 is provided with a first bolt hole 222,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com