Assembling and pressure maintaining jig

A technology for jigs and fixtures, applied in the direction of fluid pressure actuation devices, servo motor assemblies, connecting components, etc., can solve the problems of complex process, high investment cost, low processing efficiency, etc., to reduce the occupied area, the degree of automation and The effect of high production efficiency and reduced development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the assembly and pressure holding jig of the present invention in detail, specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

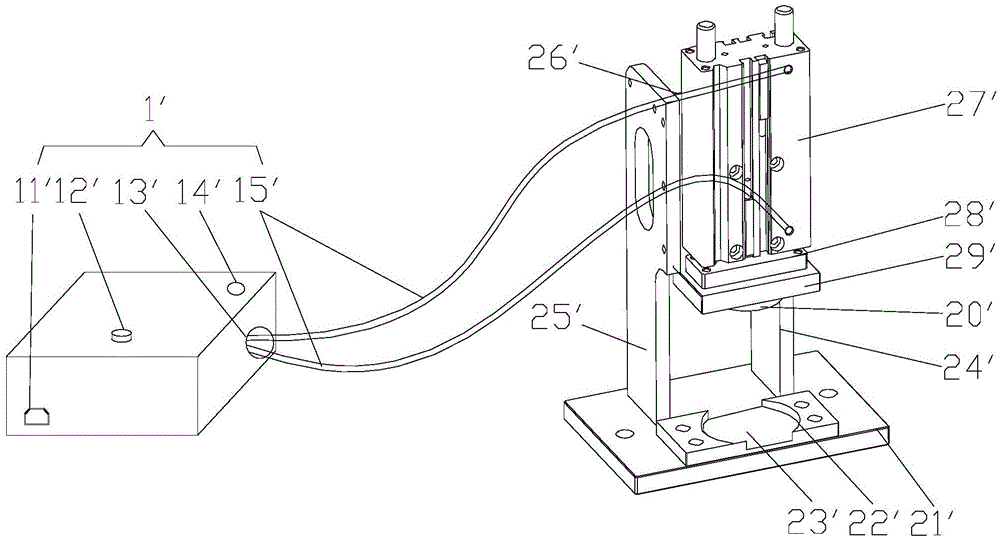

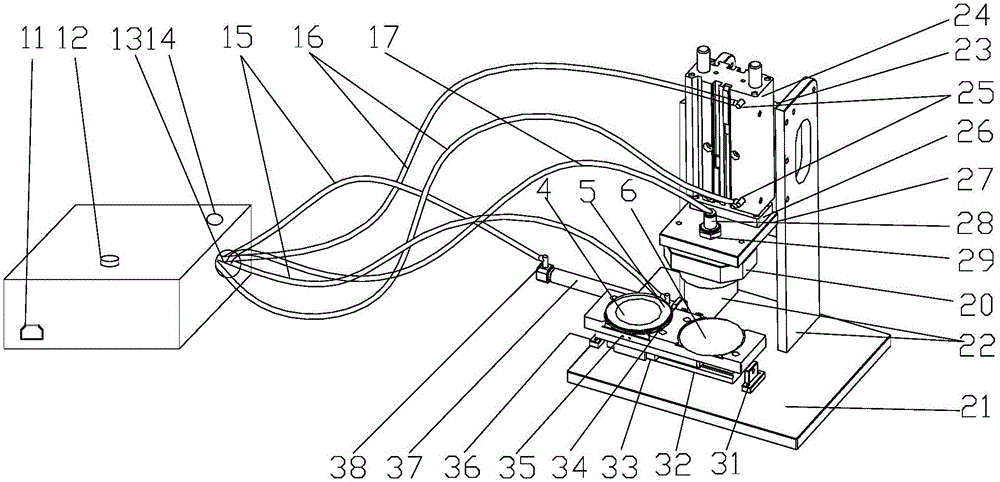

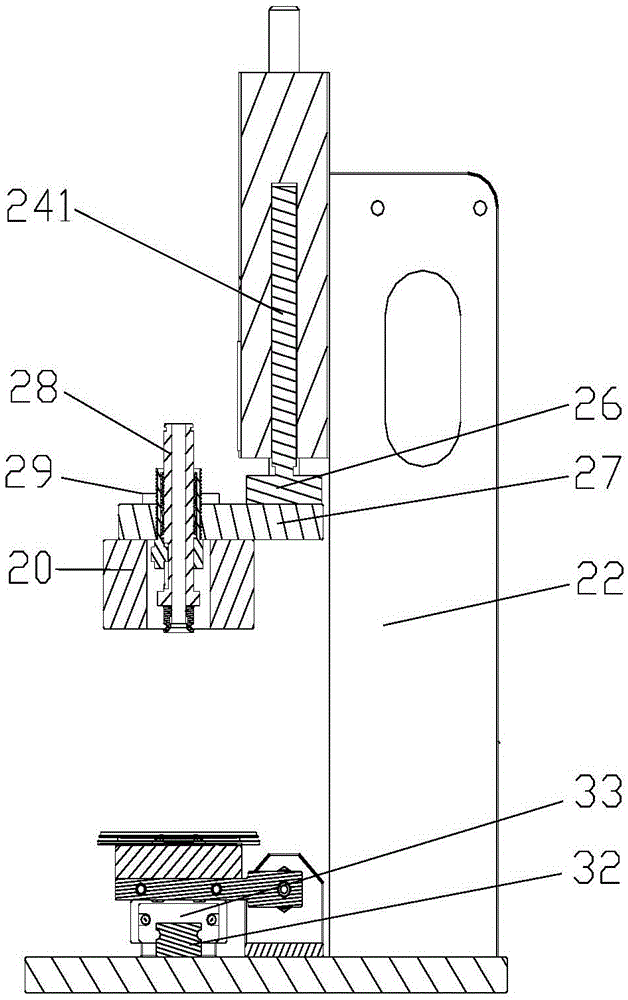

[0034] figure 2 It shows the assembly and pressure holding jig structure according to the embodiment of the present invention; image 3 The side test structure of the assembly and pressure holding fixture according to the embodiment of the present invention is shown.

[0035] Such as figure 2 and image 3 Commonly shown, the assembly and pressure-holding jig of the embodiment of the present invention includes a suction nozzle 28, a fixed tooling 35, a base plate 21, an electrical control box, and a first cylinder 24 connected to the electrical control box; There are support plates 22 (comprising the first support plate and the second support plate), connected and fixed by the cylinder connection plate 23 between each support plate 22, the first cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com