Heat shrink film

A technology of heat shrinkage and heat shrinkage rate, applied in applications, household appliances, layered products, etc., can solve the problems of inability to achieve solvent bonding, peeling, and poor solvent adhesion, and achieve excellent transparency and prevent clogging , Excellent processing suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

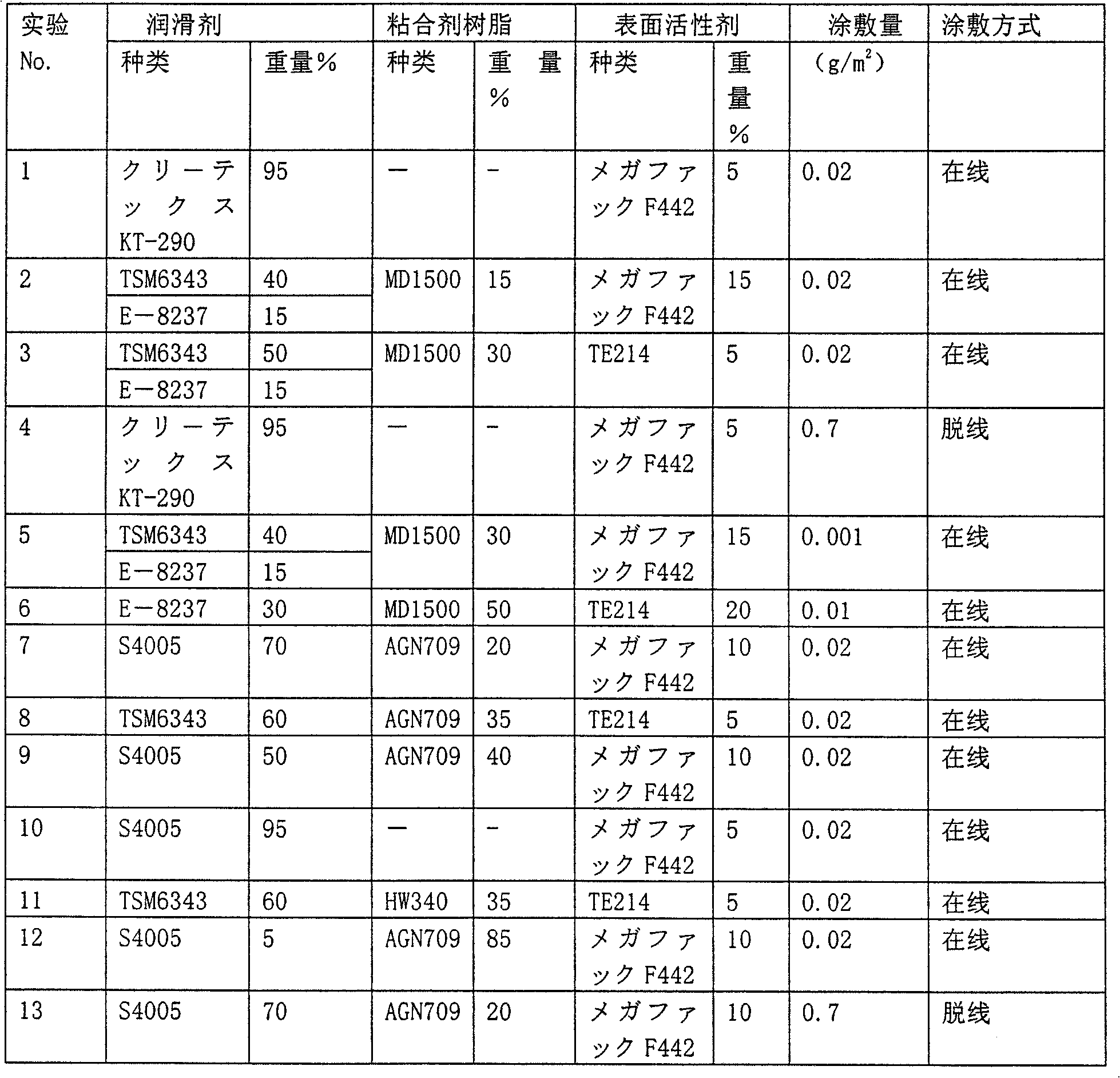

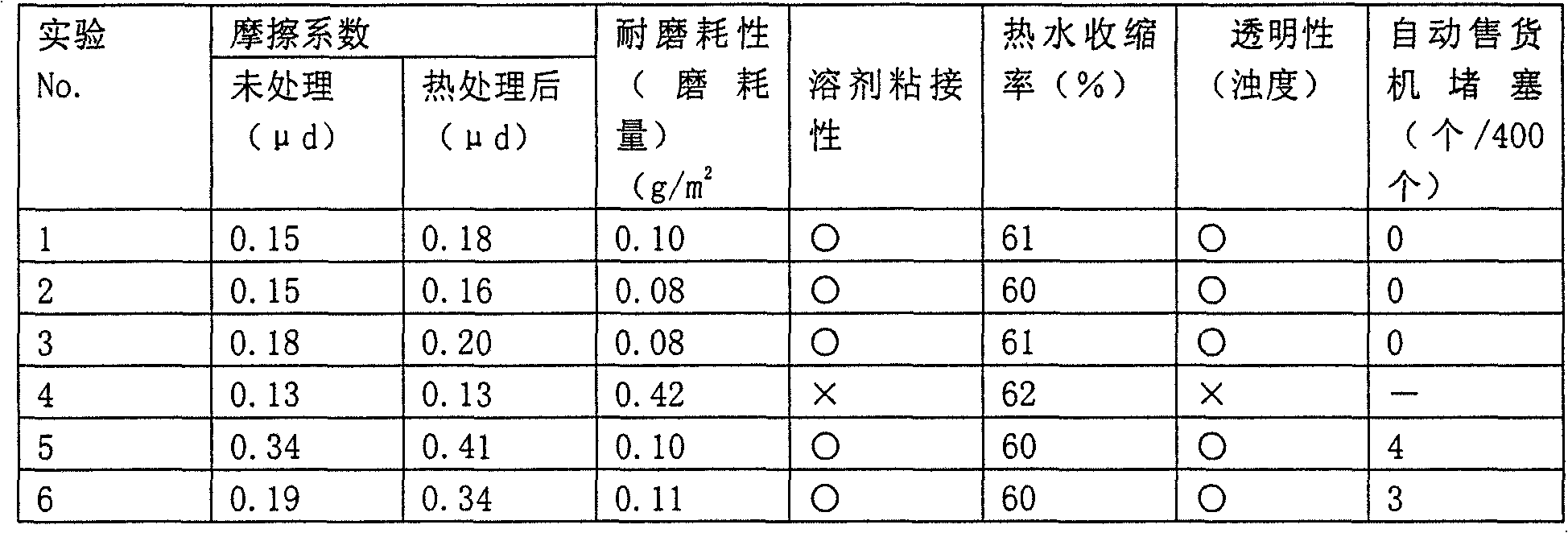

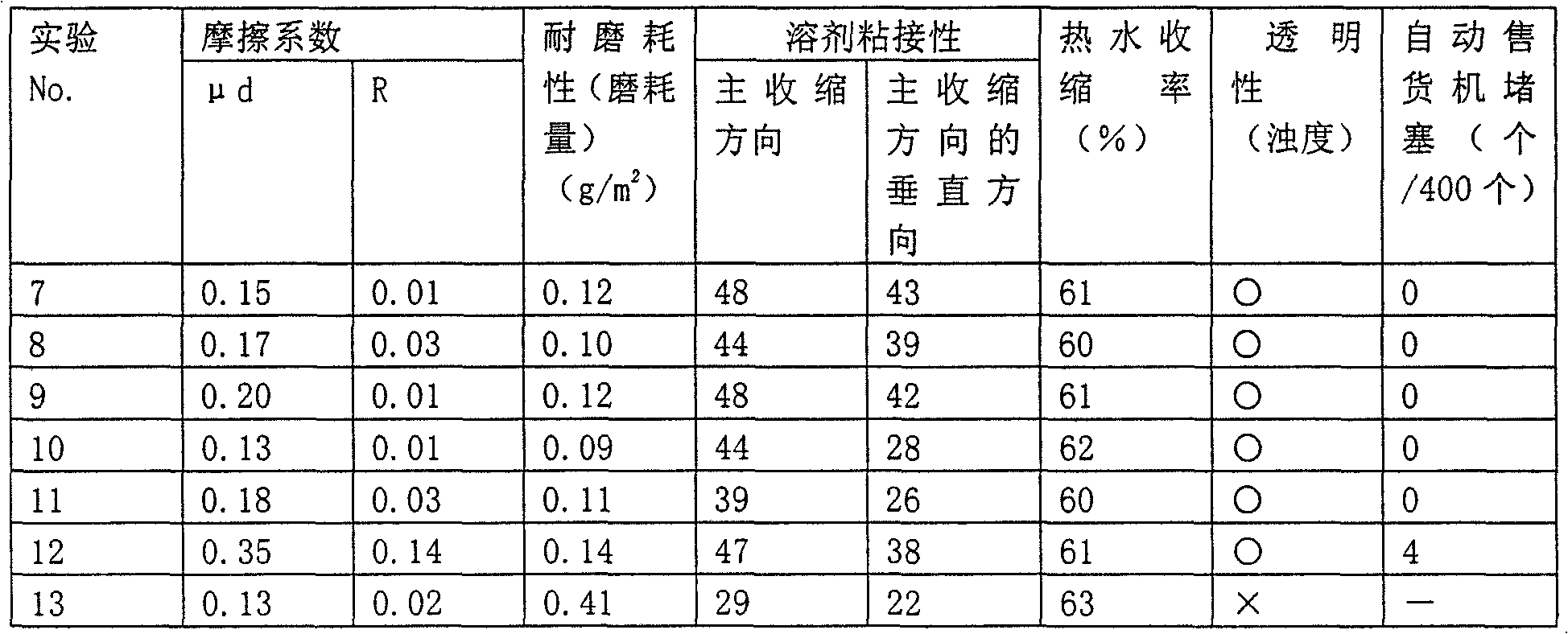

Examples

Embodiment

[0100] The present invention will be further described in detail below through the examples, but the following examples do not limit the present invention, and within the scope of not departing from the gist of the present invention, the situation of changing implementation is also included in the present invention. The methods for measuring the physical properties of the films obtained in Examples and Comparative Examples are as follows.

[0101] (1) Heat shrinkage rate

[0102] A 10 cm x 10 cm square was cut out from the stretched film so that one side thereof was parallel to the running direction of the film, and immersed in a water bath heated to 95° C. for 10 seconds. Immediately after 10 seconds, dip in a separately prepared water tank at a temperature of 23°C to 25°C for 20 seconds, then measure the length of the film in the main shrinkage direction to obtain the thermal shrinkage rate. The direction of maximum shrinkage is set as the main shrinkage direction.

[0103...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com